Original Article

, Volume: 14( 4)Identification and Evaluation of Heterophobic Phosphate-Solubilizing Potential Metal Resistant Bacterium Isolated from Linz-Donawitz Slag

- *Correspondence:

- Subarna Bhattacharyya, School of Environmental Studies, Jadavpur University, 188 Raja S. C. Mullick Road, Kolkata, India, E-Mail: barna_kol@yahoo.com

Received: August 08, 2018; Accepted: August 25, 2018; Published: August 30, 2018

Citation: Banerjee S, Bose R, Sudarshan M. et al. Identification and Evaluation of Heterophobic Phosphate-Solubilizing Potential Metal Resistant Bacterium Isolated from Linz-Donawitz Slag. Biotechnol Ind J. 2018;14(4):170.

Abstract

Linz-Donawitz (LD) slag which is a waste product of steel industry causes great disposal problem. The high concentration of calcium oxide (CaO) in the slag can partially substitute the use of limestone as a flux material in blast furnace, provided that the phosphorous (P) content of the slag can be reduced below 0.5 %. Here an attempt was made to study the phosphate solubilizing property of a bacterium, isolated from 30 days old LD slag enriched with vermi-compost (VC-1) which could solubilize 79.5% of phosphorous at 5% (w/v). Micro X-Ray Fluorescence Spectrophotometer (ED-XRF) study revealed that the isolated Bacillus sp. reduced 67.5% of total chromium, maintaining concentration of CaO, indicating that the treated LD slag could be re-used in steel processing industry. As the supernatant generated after phosphate removal was useful for seed germination which indicate that VC-1 was an effective strain in waste management in steel industry.

Keywords

Linz-Donawitz slag; Phosphorus solubilization; Bacillus sp.; Micro ED-XRF; Waste management

Introduction

Steel production in an integrated plant requires many factors, like raw materials in the form of iron ore, limestone, air, water, power, and fuel etc. During the steel making process, a substantial amount of solid waste is produced in the steel making units such as Linz–Donawitz (LD) furnace, blast furnace, Basic Oxygen Furnace (BOF), in the form of slag. Slag is a glass-like the product, which is a mixture of metal oxides and Silicon di-oxide (SiO2) and also contains certain elemental metals and sulphides of metals. In integrated steel plants, molten iron formed from the blast furnace is charged in basic oxygen furnaces along with steels craps. Usually, the BOF charge consists mainly of about 80–90 % of molten iron and around 10–20% of steel scrap (Schoenberger 2001; Brandt and Warner 2005). The main intention in using LD process is to produce high-quality steel by converting the steel scraps and molten pig iron. The production of steel melting slag in India is around 2 Metric Ton (MT) per annum. The amount of steel slag from various industries varies from 150 kg/ton to 200 kg/ton of steel production [1].

Due to its mineralogical, chemical and physical properties, it can be applied as a replacement for aggregates in civil engineering projects like road construction (TABLE 1), but the use of LD slag is restricted due to the presence of unwanted magnesium and free lime content [2]. LD slag has two useful components like CaO and magnesium oxide (MgO) for maintaining the basic quality of slag. This basic LD slag has high flux potential and can be charged into a blast furnace for better calcium utilization and eases the melting process [1]. Around 30 % of such slag is re-cycled in a blast furnace in European countries. The most unwanted components in the LD slag are phosphorous (P) and sulfur (S) which are to be removed before it can be used either in sintering plant or blast furnace. As a result, LD slag re-use in blast furnace in Bhilai Steel Plant, India was abolished due to the high concentration of phosphorous [3].

| Serial Number | Characteristics | Applications | % usage | Disadvantages |

|---|---|---|---|---|

| 1 | Hard, wear resistance, tough and rough | Can be used for road construction replacing asphalt | 48 | Restriction due to free lime content and magnesium. Heavier compared to natural rocks. |

| 2 | CaO, basicity, binding property | Cement production | 6 | Rapid shrinkage and pore formation. |

| 3 | CaO, MgO, porosity | Wastewater treatment | - | Uptake limited due to the pH of slag. |

| 4 | CaO, FeO, SiO2, MgO etc. | Reflux for sinter plant | 10 | Limited due to the presence of phosphorous. |

| 5 | Soluble P2O5, CaO, MgO, basicity | Fertilizer or soil conditioner | 3 | Leaching of heavy metals is a possibility. |

TABLE 1. Applications and limitations of LD slag [2,6].

It is also inapt for cement making due to the high percentage of iron oxide, and in a blast furnace or sintering plants due to its high phosphorous content. LD slag can be re-used as a substitute for limestone due to its high CaO content as fluxing material to reduce the steelmaking cost provided its phosphorous content is reduced below < 0.5% [4-6].

Reduction of phosphorus content from LD slag through microbial pathway needs to be explored, to maintain the sustainability of the process. Earlier studies with bacteria Frateuria aurantia has been reported by Pradhan [7]. The studies were conducted at 10 % (v/v) inoculation, which removed around 72.17 % phosphorous from the LD slag [7]. The bacterium Burkholderia caribensis FeGL03, isolated from a Brazilian iron ore containing a high level of phosphorous, was also used to mobilize the phosphorous content in the ore [8]. Specific microorganisms such as Aspergillus niger, Hyphomicrobium, and Bacillus mucilaginosus are routinely being used for the removal of phosphate from ores, sludge, etc. Their efficiency in phosphorous solubilization was initially studied with tri-calcium phosphate as a model source of insoluble phosphate compound at various sugar concentrations, NaCl concentrations and at varying pH of the medium. About 35 % of phosphorous could be solubilized from LD slag by Pseudomonas aeruginosa at 2 % solid content [5].

In our study, an effort was made to study the phosphate solubilizing and metal resistance of a bacterium isolated from the 30 days old enriched LD slag collected from Tata Steel yard, Jamshedpur, India. Our results may afford a potential microbial resource for phosphate removal from LD slag containing toxic heavy metal, and it may also be beneficial to clarify the mechanisms of heterotrophic phosphate solubilization by the bacteria Bacillus sp.

Materials and Methods

Characterization of slag

The 30 days old slag used for the experiment was collected from Tata Steel yard and the 6-7 years old slag was collected from the dumping yard at Mahulia (22°39′0″N 86°24′0″E, 93m MSL) which is around 30 km from Jamshedpur, Jharkhand, India. Moisture content, organic carbon content, available nitrogen and phosphorus content were studied for the collected sample (TABLE 1).

Enrichment of LD slag

30 days old LD slag (diameter <0.15 mm) was enriched with an easily available commercial fertilizer, vermicompost in a ratio of 1:1 under laboratory conditions and incubated at 37° C. It was periodically moistened with water and was tested for physicochemical parameters (viz. Moisture content, organic carbon content, available nitrogen and phosphorus content) on a weekly basis up to 4 weeks (TABLE 2), beyond which no noticeable difference was observed. After a 30 days interval, it was analyzed for the same physicochemical parameters.

| Parameters | 30 days old slag | 6-7 years old slag | 30 days old slag enriched with vermicompost |

|---|---|---|---|

| Moisture | 11.66 | 4.19 | 57.49 |

| Organic carbon | 0.23 | 0.33 | 4.3 |

| Available Nitrogen (ppm) | BDL** | BDL** | 0.15 |

| Available Phosphorus | 1.07 | 0.64 | 0.03 |

| Magnesium | 6.84 | 5.55 | 5.84 |

| Silicon | 28.86 | 28.36 | 29.4 |

| Phosphorus | 4.88 | 4.67 | 5.08 |

| Sulfur | 2.48 | 2.17 | 2.8 |

| Calcium | 39.11 | 38.52 | 38.15 |

| Chromium | 0.47 | 0.47 | 0.47 |

| Manganese | 0.5 | 0.3 | 0.3 |

| Iron | 18.45 | 18.26 | 18.46 |

| pH | 12±0.4 | 12±0.4 | 12.5±0.2 |

*Except available Nitrogen all values are shown in % (w/w). **BDL = Below Detection Level.

TABLE 2. Characterization of LD slag before and after enrichment with vermicompost.

Isolation of true phosphate solubilizer from enriched slag

Bacteria were isolated on nutrient agar plates from both enriched and non-enriched 30 days old slag. After 24 hours of growth, the individual colonies were grown on petridishes containing Pikovskaya Agar (PVK Agar) (Pikovskaya 1948), which consists of yeast extract (0.500 g/L), dextrose (10 g/L), calcium phosphate (5 g/L), ammonium sulphate (0.500 g/L), potassium chloride (0.200 g/L), magnesium sulphate (0.100 g/L), manganese sulphate (0.0001 g/L), ferrous sulphate (0.0001 g/L) and agar (15 g/L) and modified PVK Agar (US6638730B2) [9], containing bromophenol blue indicator and incubated at 37° C for 24-48 hours for detecting their phosphate solubilization potential.

Individual colonies were isolated and named. It was found that bacterium vermicompost-1 (VC-1) was the most effective phosphate solubilizer and thus selected for further experiments.

Biochemical Characterization of isolated strain

The growth characteristics of the bacterium were studied first. After which the optimum growth condition of the bacteria was studied under the influence of different pH, temperature, glucose, and sodium chloride. Also, their biochemical responses were studied in accordance with Bergey’s Manual of Determinative Bacteriology [10].

DNA extraction and PCR amplification

DNA was isolated from the culture of the bacterium VC-1, as it yielded better phosphorous solubilization efficiency and its quality was assessed in 1.2 % agarose gel. The 16S rRNA of the isolated DNA was amplified with a universal primer (8F and 1492R) using Veriti® 99 well Thermal Cycler (Model No. 9902). The PCR amplicon was eluted enzymatically and sequenced further using Sanger’s chain termination method. Also, the bi-directional DNA sequencing reaction of the PCR amplicon was carried out using BDT v3.1 Cycle sequencing kit on ABI 3730*l Genetic Analyzer with 704F and 907R universal primers. Basic Local Alignment Search Tool (BLAST) analysis was then carried out for the amplified 16S rDNA sequence for phylogenetic analysis taking the aid of NCBI GenBank database. Based on the maximum identity score, the first fifteen sequences were selected and the alignment was performed using multiple alignment software program Clustal-W. Distance matrix was then generated using RDP database and the phylogenetic tree was generated employing MEGA5.

Assessment of de-phosphorylation of LD Slag

The phosphorous removal efficiency was tested for three different weights of slag i.e. 2%, 5% and 10% (w/v). 24 hours old culture of each bacterium was used as inoculum at 10% (v/v) ratio for this experiment.

Estimation of phosphate reduction: Solid and liquid state analysis

The amount of phosphate reduction was measured as a percentage of residual phosphorus in the liquid media which was sampled out daily for 7 days. At the end of 7th day, the slag was collected, filtered and washed with distilled water thrice and dried in a hot air oven, after which it was analyzed by micro X-Ray fluorescence spectrophotometer (Horiba Scientific, XGT-7200) to detect the amount of phosphorus remaining in the slag. The concentration of inorganic phosphorus released in the medium as phosphate (PO4) was analyzed using vanado-ammonium molybdate method [11].

Seed germination study using supernatant of the treated LD slag

Two seed varieties, Chickpea (Cicer arietinum), a dicot species and Wheat (Triticum aestivum), a monocot species were chosen. Their germination rate was studied using the liquid broth which was collected after separating the 7 days treated solid slag. This study was done to check the suitability of the liquid broth left after phosphorous removal from LD Slag (which can be re-used as a flux material in the furnace) for agricultural purposes. A control was maintained using autoclaved distilled water.

Results and Discussion

Characterization of LD slag

Elemental analysis of LD slag was done using micro XRF to find out the probable presence of elements like carbon, phosphorus, nitrogen, sulfur etc. The surface constituents of LD slag was non-homogenous and rough (FIG. 1) and the presence of carbon and nitrogen in the slag was negligible.

The pH of the untreated LD slag was found to be 12 (TABLE 2). The main composition of the slag was calcium, silicon, iron, manganese, magnesium, aluminum, sulfur, and phosphorus as was analyzed using ED-XRF, which usually exists in oxides forms. A similar result was reported by Chand et al. [6] for different slag samples where the major constituents in weight percent are calcium oxide (CaO-47.88%) followed by ferrous oxide (FeO-26.30%) and silicon dioxide (SiO2-12.6%). In the present study, the total elemental phosphorous content of the LD slag between 3.60-5.43 weight percent. The composition of phosphorus-rich LD slag as indicated by micro XRF study was in concordance with a previous study by [12] where the phosphorous content was found in between 3-7 weight percent.

The phosphorous content (as analyzed by the electron probe micro analyzer, EPMA) varied from 0.67-3.56 weight percent for different samples of LD slag collected from two different dumping sites across India as reported in the study conducted by Das et al. [1]. Slag collected from Bokaro Steel Plant, India consisted of higher percentage of calcium (Ca), silicon (Si) and iron (Fe) [13] and were similar to the slag sample used in this study collected from Tata Steel dumping ground at Mahulia, India in terms of mineral composition. Both the freshly generated slag and 30 days old slag sample, however, had zero or very little organic carbon and nitrogen residue. In general, for plant growth, carbon, nitrogen, phosphorous and potassium are considered as the macro-nutrients. Typically for plant growth the nutrient requirements are 1.25% - 4% (w/w) nitrogen, 0.15% - 0.8% (w/w) phosphorous and 1% - 5% (w/w) potassium; carbon can be fixed from the atmosphere as CO2 and an optimum pH of 5.5-7.0. From the analysis, we can see that LD slag contains all nutrients except for nitrogen and organic carbon in sufficient quantity (TABLE 2), and can be used as a soil conditioner for acidic soils which lacks an adequate amount of phosphorous.

Active phosphate solubilizing microorganisms could not be isolated from the untreated slag, so the 30 days old slag was enriched with easily available vermicompost and incubated at an ambient temperature of 37° C for one month for isolating phosphate solubilizing bacteria. Except organic carbon, available nitrogen and phosphorous, the other elemental concentrations remained almost the same for both enriched and non-enriched LD slag (TABLE 2). The increase in available phosphate content during composting can be attributed to the breakdown of organic matter as is also explained by some previous studies where enrichment of compost and vermicompost in rocky soil increased the availability of phosphorus [14,15] and nitrogen [16]. Also, the active microorganisms and organic matters in the vermicompost increased the level of organic carbon and other nutrients in the enriched slag.

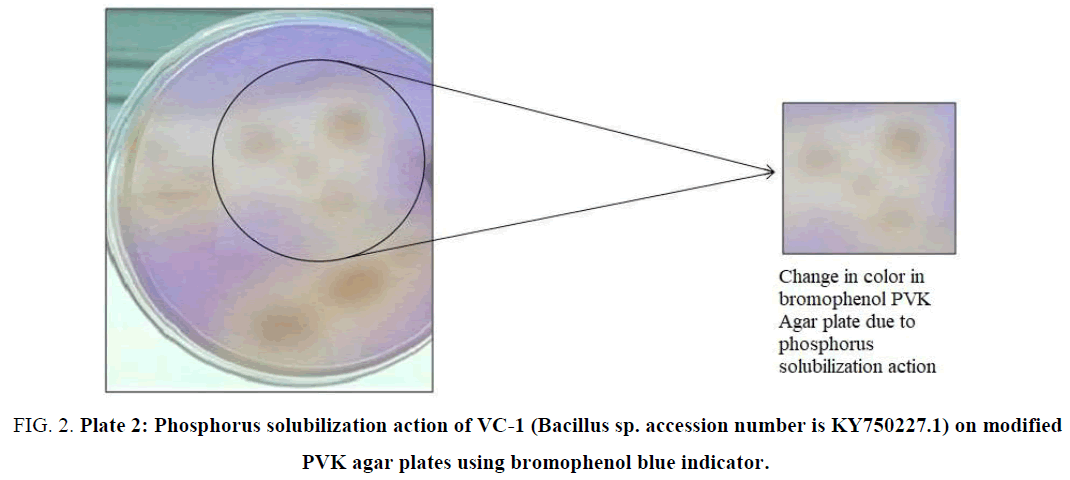

Isolation and characterization of bacterial strain

Microbes that were directly isolated from the 30 days old slag and 6-7 years old slag, did not fulfill the criteria of true phosphate solubilizers in the PVK media. After enrichment with vermicompost, five different individual bacterial colonies were isolated in our primary screening step which was further subjected to modified PVK media (which had bromophenol blue indicator) for isolation of true phosphate solubilizers (FIG. 2).

FIG. 2. Plate 2: Phosphorus solubilization action of VC-1 (Bacillus sp. accession number is KY750227.1) on modified PVK agar plates using bromophenol blue indicator.

Among the isolates, the most potential phosphate solubilizer was then selected and designated as VC-1 (for the bacterium isolated from enrichment with vermicompost) due to the de-colorization effect on bromophenol blue as a result of a reduction in pH. The colony morphology of the isolate was irregular and lobate, with a flat and smooth surface. The growth cycle of the bacterium was about 27 hours (log phase was from 2.5-18 hours, and a brief stationary phase). The optimal temperature for growth was 37° C and the favorable pH was 7; however, the organism grows well at higher pH ( 8-10) also. The ability of the bacterium to survive at higher pH is beneficial for its exploitation as a phosphorous scavenger in an alkaline environment like that of LD slag (pH = 11-12). The bacterium can also tolerate as high as 8% (w/v) NaCl and 5% (w/v) sugar concentrations.

The biochemical analysis of the bacterium VC-1 showed that it was a Gram-positive, rod-shaped bacillus.

Molecular identification of the bacterium VC-1

The DNA of bacterium VC-1 was isolated and its 16S rRNA was amplified using polymerase chain reaction and was subjected to Sanger sequencing. A single discrete PCR amplicon band of 1500 bps was detected. A consensus sequence of 1413 bps 16S rDNA was generated from forward and reverse sequence data using Aligner software. The sequence was submitted to GenBank database (Accession Number is KY750227.1) and a sequence homology using BLAST indicated that the strain VC-1 was most closely related to Bacillus sp., WJ12 (Accession Number: HM045836.1) with 99% sequence similarity. A phylogenetic tree was constructed using Neighbor-Joining method based on the partial 16S rRNA sequence of the isolate VC-1 and related organisms.

Heavy metal tolerance of the isolated strain

The heavy metal tolerance capacity of the isolated Bacillus sp. VC-1 was checked under laboratory conditions after phosphorous solubilization study of LD slag which was largely laden with heavy metals. VC-1 could tolerate 40 μg/mL, 36 μg/mL, 400 μg/mL, 500 μg/mL and 360 μg/mL each of mercury (Hg), silver (Ag), lead (Pb [II]), chromium (Cr [VI]) and arsenic (As [III]) respectively. It was in concordance with the work done by Pandey et al. [17] where they isolated and characterized arsenic and lead tolerant bacteria AsSP9 and PbSP6 from Burnpur steel plant dumping ground. These strains could tolerate between 20-800 μg/mL of each metal.

The results indicate that these bacteria can survive in a heavy metal contaminated environment like that found in LD slag and can, therefore, be used to study the phosphorous solubilization action when grown under suitable conditions.

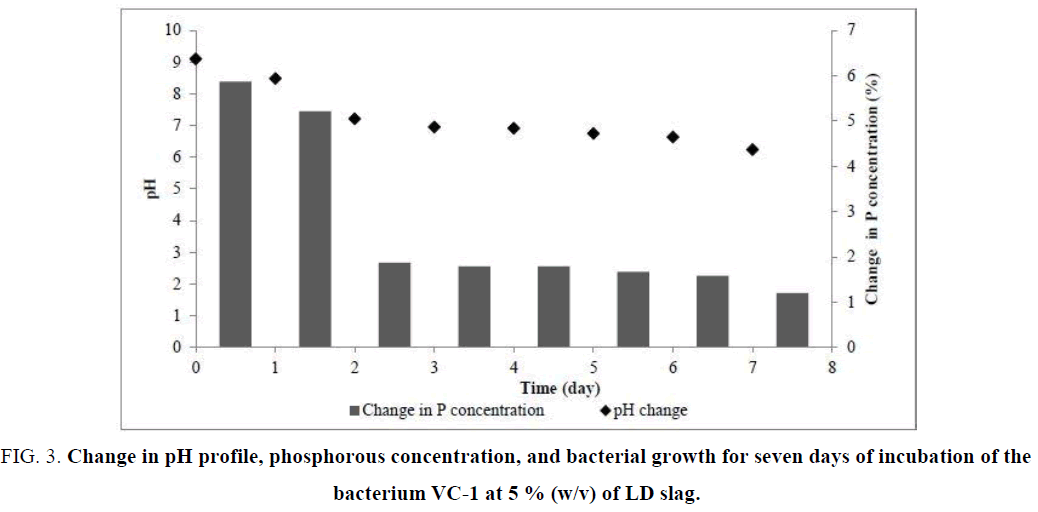

Change in pH

A linear decrease in pH was observed with respect to time during the phosphorous solubilization experiment. The final pH after 7 days of the study was 6.24 ± 0.05 for VC-1 at 5% (w/v) of LD slag containing media (FIG. 3). The decrease in pH was synchronous with the growth of bacteria, reaching the value of pH of 6.24 ± 0.5 after 168 hours due to the release of organic acids by the bacteria during their growth (Plate 2). The phosphate solubilization process by microbes releases organic acids like butyric acid, citric acid, gluconic acid, malic acid etc. [18] which convert the unavailable phosphate to available form [7].

FIG. 3. Change in pH profile, phosphorous concentration, and bacterial growth for seven days of incubation of the bacterium VC-1 at 5 % (w/v) of LD slag.

Phosphorus solubilization by Bacillus sp. VC-1

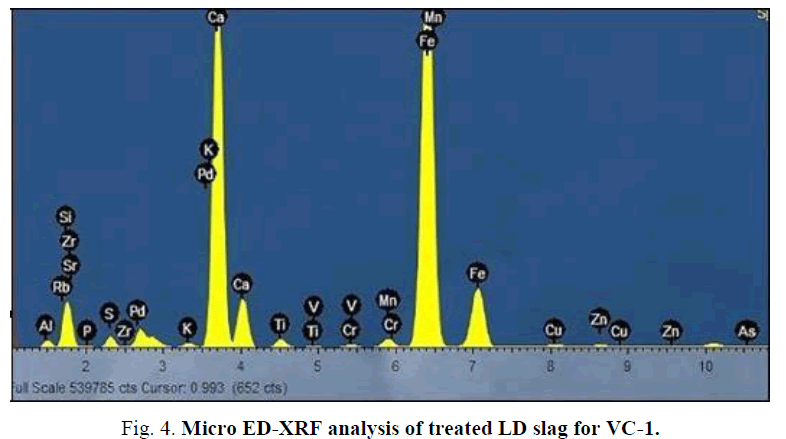

A considerable amount of reduction in phosphorous concentration was observed when LD slag was treated using the isolated Bacillus sp. VC-1 grown in PVK media. There was 40.04% reduction in the phosphorous concentration when measured in terms of residual phosphate concentration using vanado-ammonium molybdate method as described by Vogel (1978), when LD slag was used at 2% (w/v) ratio. The reductions in phosphorous content were 71.03% and 17.80% when LD slag was used at 5% (w/v) and 10% (w/v) respectively. A maximum reduction of 79.5% at 5% (w/v) solid content of LD slag (solid state analysis by ED-XRF) was achieved (FIG. 1) using Bacillus sp. VC-1 (TABLE 3). The reduction decreased when 10% (w/v) LD slag was used. This may be due to the toxicity of material, increased alkalinity, nutrient, and oxygen limitation as suggested by Marhual et al. [5].

| Trace elements | Concentration (%) before treatment | Concentration (%) after treatment with VC-1 |

|---|---|---|

| Si | 23.53 | 23.46 |

| P | 5.87 | 1.2 |

| S | 1.41 | 1.39 |

| Ca | 34.27 | 33.82 |

| Ti | 0.77 | 0.77 |

| Cr | 0.4 | 0.13 |

| Mn | 0.33 | 0.33 |

| Fe | 18.26 | 18.13 |

Table 3. Elemental analysis of LD slag after treatment with bacterium VC-1 [Slag at 5 % (w/v)].

Micro XRF analysis (FIG. 4) also suggested that the calcium, iron, aluminum and silicon levels remained unchanged, but the levels of phosphorus and chromium reduced after treatment with VC- 1 significantly (TABLE 3).

The organic acids produced by many phosphate solubilizers in a natural environment or in-vitro studies, led to the pH decline of the medium to almost 4.5 [5]. Phosphorus solubilizing microorganisms are reported to convert insoluble phosphates into a soluble form, by the production of organic or inorganic acids, leading to a subsequent reduction in pH. Simultaneous production of various organic acids by Bacillus sp. VC-1 may have contributed towards the decrease in pH which in turn leads to a greater potential for solubilization of insoluble phosphates [19].

Utilization of treated slag residue in seed germination

Seed germination had 20% enhancement when grown in slag supernatant as compared to germination in distilled water, reflecting that the liquid portion after the phosphorous solubilization activity could be used for agricultural purpose and soil improvement because the slag contains CaO, SiO2, MgO, FeO which are known fertilizer components [20,21].

Conclusion

Phosphate solubilizing microorganisms which include Actinomycetes, bacteria, yeast and many fungi solubilize phosphorous mainly by the production of organic acids which act as a source of protons and are also chelators leading to a decrease in pH of the solution. The isolated bacterial strain VC-1 belonging to Bacillus group (Accession Number is KY750227.1), was best suited for phosphorous solubilization which could thrive and flourish in the highly alkaline LD slag.

About 79.5% of phosphorous could be removed from LD slag through solubilization at 5% (w/v) solid content which was more economically viable as compared to the previous work done so far (TABLE 4). The de-phosphorized LD slag can, therefore, be reused as a flux material in iron and steel making processes thus reducing the solid waste generated in the process.

| Serial Number | Slag content | Reduction (%) | Experiment duration (days) | Organism used | Inoculation volume (% v/v) | Reference |

|---|---|---|---|---|---|---|

| 1 | 2 % solid content | 35 | 7 | Pseudomonas aeruginosa | 10 | Marhual et al., 2011 |

| 2 | - | 72 | 13 | Frateuria aurentia | 10 | Pradhan et al., 2004 |

| 3 | 5 % (w/v) solid content | 79.5 | 7 | Bacillus sp. VC-1 | 10 | Current study |

Table 4. Comparison of phosphorous solubilization using different bacteria.

Acknowledgment

This research work was supported by Jadavpur University, India. We express our sincere thanks to Trace Element Laboratory, UGC-DAE CSR Kolkata for Micro ED-XRF sample preparation and image generation.

References

- Das B, Prakash S, Reddy PS, et al. An overview of utilization of slag and sludge from steel industries. Resources, conservation and recycling. 2007;50(1):40-57.

- Lim JW, Chew LH, Choong TS, et al. Utilizing steel slag in environmental application-An overview. InIOP Conference Series: Earth Environ Sci. 2016;36(1).

- Romano LA, Sampaio LA, Tesser MB. Micobacteriosis by Mycobacterium marinum in Brazilian flounder Paralichthys orbignyanus and barber goby Elacatinus figaro: histopathological and imunohistochemical diagnosis. Pesquisa Veterinária Brasileira. 2012;32(3):254-8.

- Umadevi T, Rao SR, Roy P, et al. Influence of LD slag on iron ore sinter properties and productivity. In proceedings of the XI International Seminar on Mineral Processing Technology (MPT-2010) 2010; 2(10);747-57.

- Marhual NP, Pradhan N, Mohanta NC, et al. Dephosphorization of LD slag by phosphorus solubilising bacteria. "Int Biodeterior Biodegradation. 2011;65(3):404-9.

- Chand S, Paul B, Kumar M. Sustainable approaches for LD slag waste management in steel industries: a review. Metallurgist. 2016;60(1-2):116-28.

- Pradhan N, Das B, Acharya S, et al. Removal of phosphorus from LD slag using heterotrophic bacteria. Miner. Metall. Process.. 2004;21(3):149-52.

- Delvasto P, Ballester A, Muñoz JA, et al. Mobilization of phosphorus from iron ore by the bacterium Burkholderia caribensis FeGL03. Miner. Eng. 2009;22(1):1-9.

- Nautiyal, C. S., Mehta S., Pushpangadan, P.U.S. Patent No. 6,638,730. Washington, DC: U.S. Patent and Trademark Office.2003.

- Samal S, Mohapatra BK, Mukherjee PS, et al. Integrated XRD, EPMA and XRF study of ilmenite and titania slag used in pigment production. J Alloys Compd. 2009;474(1-2):484-9.

- Vogel I. A Text-Book of Quantitative inorganic analysis including elementary instrumental analysis: the english language book society and longmans, Green & Co. Ltd. pp. 1961;358.

- Schoenberger H. Final draft: best available techniques reference document on the production of iron and steel. Publications of EC: European Commission, Joint Research Centre, IPTS, European IPPC Bureau. 2001.

- Singh R, Gorai AK, Segaran RG. Characterisation of LD slag of Bokaro Steel Plant and its feasibility study of manufacturing commercial ‘fly ash–LD slag’bricks. Int. J. Environ Technol Manage. 2013;16(1-2):129-45.

- Busato JG, Lima LS, Aguiar NO, et al. Changes in labile phosphorus forms during maturation of vermicompost enriched with phosphorus-solubilizing and diazotrophic bacteria. Bioresour Technol.. 2012;110:390-5.

- Bustamante MA, Ceglie FG, Aly A, et al. Phosphorus availability from rock phosphate: combined effect of green waste composting and sulfur addition. J Environ Manage.. 2016;182:557-63.

- Awasthi MK, Pandey AK, Bundela PS, et al. Co-composting of gelatin industry sludge combined with organic fraction of municipal solid waste and poultry waste employing zeolite mixed with enriched nitrifying bacterial consortium. Bioresour Technol. 2016;213:181-9.

- Pandey S, Saha P, Biswas S, et al. Characterization of two metal resistant Bacillus strains isolated from slag disposal site at Burnpur, India. J Environ Biol. 2011;32(6):773.

- Yadav H, Gothwal RK, Nigam VK, et al. Optimization of culture conditions for phosphate solubilization by a thermo-tolerant phosphate-solubilizing bacterium Brevibacillus sp. BISR-HY65 isolated from phosphate mines. Biocatal Agric Biotechnol. 2013;2(3):217-25.

- Marra LM, Soares CR, de Oliveira SM, et al. Biological nitrogen fixation and phosphate solubilization by bacteria isolated from tropical soils. Plant Soil. 2012;357(1-2):289-307.

- Navarro C, Di?az M, Villa-Garci?a MA. Physico-chemical characterization of steel slag. Study of its behavior under simulated environmental conditions. Environ Sci Technol. 2010;44(14):5383-8.

- Pikovskaya RI. Mobilization of phosphorus in soil in connection with vital activity of some microbial species. Mikrobiologiya. 1948;17:362-70.