Research

, Volume: 18( 1)A Study of Occupational Noise Exposure among Gold Miners at Anglo Gold Ashanti Limited (Obuasi)

- *Correspondence:

- Bernard Kwame EssandohGhana Prisons Service, Kumasi, Ghana Tel: +233552777504; E-Mail: attoquamena@yahoo.co.uk

Received: December 29, 2021, Manuscript No. TSES-21-46962; Editor assigned: January 03, 2022, Pre QC No. TSES-21-46962(PQ); Reviewed: January 14, 2022, QC No. TSES-21-46962; Revised: January 20, 2022, Manuscript No: TSES-21-46962(R); Published: January 28, 2022, DOI: 10.37532/environmental-science.2022.18.208

Citation: Essandoh BK, Belford EJD, Anomah JE. A Study of Occupational Noise Exposure among Gold Miners at Anglo Gold Ashanti Limited (Obuasi). Environ Sci Ind J. 18(01):208

Abstract

Underground and surface gold miners working at Anglo Gold Ashanti Limited (Obuasi) are potentially exposed to high noise levels from the mining activities, especially noise emitted by the heavy equipment’s in the mines. Results obtained indicate that there is a statistically significant (P0.05) difference between the mean occupational noise exposure for Continuous Equivalent Level, LAeq.8hrs (92.5 ± 9.00 dB (A)) and the recommended standard of 85 dB (A). The research findings equally indicate that, the primary risk of exposure to noise by miners of AngloGold Ashanti comes from work activities such as drilling, blasting, machine operating, processing, ventilation and transportation. All occupational types were found to be susceptible to noise levels which were potentially harmful. The incidence of tinnitus was found in 56.8% of the miners sampled whilst annoyance, high blood pressure and headaches were found to be 23%. The study highlights that miners are exposed to hazardous noise levels which inevitably affect their hearing acuity. Enforcement in the use of hearing protective devices must therefore be encouraged.

Keywords

Celosia; Drought stress; DUF538; Gene expression; Real-Time PCR

Introduction

Prolonged exposure to noise can result in permanent damage to the auditory nerve and/or its sensory components. This irreversible damage, known as Noise-Induced Hearing Loss (NIHL) is particularly severe in all areas of mining, with studies indicating that 70% to 90% of all miners have NIHL great enough to be classified as a hearing disability. The exposure of the human ear to high intensities of noise, results in a sensory-neural hearing loss or what is known as NIHL [1]. NIHL is characteristically a hearing loss where the damage incurred is chiefly to the cochlear hair cells which are responsible for converting sound energy to electrical signals transmitted to the brain. This damage may be the result of direct mechanical trauma to the delicate organ of corti structures or the result of overdriving the metabolically dependent processes of the inner ear. The gold mining industry has certain attributes that could impact on the hearing acuity of miners. Miners work for many hours in the presence of high level of noise from machinery such as drilling, ventilation and transportation equipment in confined areas. The research organization of the South Africa chamber of mines has reported that mining equipment’s such as jackhammer, pneumatic drills, ball mills, air compressor, equipments for bending, riveting, grinding and cutting steel plate are known to emit noise levels of up to 110 dB (A) [2]. A good number of factors in the development of NIHL have been scientifically proven as possible contributing reasons for the individual susceptibility. The main factor appears to be that of the age of the subject. Most of the research into the combined effects of age and noise exposure, has led to the conclusion that, the effect of NIHL and Age Related Hearing Loss (ARHL) are additive in nature. Research in NIHL has resulted in the development of graphs indicating the expected hearing sensitivity levels for progressively older subjects in relation to the exposure periods [3,4]. Other factors that influence the individual susceptibility of NIHL featuring in recent research include the effects of dynamic physical exercise, toxin, drugs and smoking [4-6].

What is disturbing is the fact that, an important aspect of NIHL can be prevented by introducing effective hearing conservation programmes. Such programmes advocate noise control engineering as the main method of minimizing the risk of NIHL [6]. Development in technology, both in the fields of measurement of hearing and the most effective reduction of noise, undoubtedly leads to improvement in conservation SABS, 1996 . They provide standard procedures whereby specific details of worker’s hearing loss can be monitored to give early indication of subtle alteration to hearing function. Research has suggested the possibilities of further preventing NIHL by pharmacological means and by means of sound conditioning or prior exposure to low-level noise. Although literature abounds in the area of hazardous noise exposure and its effects in the western world, the same cannot be said about the developing countries. These issues have received little attention in Ghana due to the widespread and culturally rooted lack of awareness regarding the importance of a safe and healthy working environment, and to the weakness of the institution responsible for the promotion and enforcement of better working conditions. To address this problem requires reliable, representative and factual data relating to noise emission levels, duration of exposure, as well as the effects that actually exist in our environment. This will provide the basis for effective engineering and administrative controls, and the use of personal protective equipment, to reduce noise exposures among the mining workforce [7].

Materials and Methods

Survey of study area

The study was conducted in the Obuasi municipality. The municipality is located at the southern part of Ashanti region between latitude 5.35N and 5.65N and longitude 6.35N and 6.90N. It covers a land area of 162.4 sq km. It is bounded to the east by Adansi South, west by Amansie Central, to the north by Adansi North, and to the south by Upper Denkyira District in the central region. It has Obuasi as its administrative capital where AngloGold Ashanti limited, Ghana is located. The population of the municipality is estimated at 175,043 using the 2021 Housing and Population Census as a base and applying a 4% annual growth rate.

Calibration of instruments

The noise exposure data was recorded using a mini Sound Level Meter (SLM) Bruel and Kjaer investigator type 2250–L and three unit of noise logging Casella CEL Dose Badge (DB) with integrated display. In accordance with regulations (SABS, 2004) the SLM together with noise dosimeter was calibrated before and after their usage. This is because the instruments may have been subjected to vibration, shock and excessive heat on their way to measurement site which could have influenced the accuracy of the instruments [8].

Data Collection

Measurement of underground noise using the personal noise dosimeter

The underground noise levels were measured using the personal noise dosimeter (dose badge) Casella CEL d badge with integrated display. This instrument was effective for measuring underground noise levels in deep gold mining environment where miners move from one point to the other. Data was collected from the underground miners working in four different operating shafts in the mines namely; Adansi (AD), Sansu (SAN), George Cappendel (GC) and Kwasi Mensah (KM). Data was obtained from each shaft on 12/12 different occasions. Sampling was done on Mondays and Fridays for 5/5 months.

‘Underground miners’ exposures to noise levels were determined from five miners from each shaft. They were randomly selected and administered with the dose badge after they had completed a questionnaire.

Full shifts were measured using slow response and A-weighting, and data recorded. For each dose badge issued, records such as the instrument identification and serial number as well as the name, occupation and workplace (operating shaft and activity area) of the worker to whom it is issued were obtained.

Measurement of surface noise using the sound level meter

A survey was conducted to designate certain areas with harmful noise levels (i.e. the red areas) where employees work. Data was collected from the surface miners working from seven different workshops in the mines namely; Carpentry (CAR), Power Station (PST), Raise Boring (RBS), Plate Shop (PS), Machine Shop (MS), Sulfide Treatment Plants (STP) and Tailing Treatment Plant (TTP). Data was obtained from each workshop at five different times (i.e. measurements were taken for a period of 20-30 seconds) from four sampling points after the demarcation of the workshops. The level of noise recorded by the SLM was taken as the reference level of noise that was emitted from the workshop to which surface miners are exposed. Again to ensure that noise from all other sources besides the miner’s own machine were accurately measured; the microphone of the mini-SLM was Omni-directional (i.e. one directional).

Noise measurements were measured at the position of the miners’ head while they kept their normal work posture. The main noise sources at the various workshops were as follows; band saw machine, copy lathe machine, cross-cut machine, chin-saw machine, guillotine, hydraulic hummer, saw cutting machine, spot-welding machine, drilling machine, centex compressor, seal air compressor, primary water pump secondary water pump, millear, grinding machine, alimak, diamond drill, diamec machine, cutting machine, lathe machine, boring machine, diesing machine, milling machine, crusher, oven, syntron, furnace, extractor fan, hood/fume extractor, bail mill machine and exhaust fan.

The unit employed for expressing the values is the decibel (dB), set at A-weighting network. Again the SLM was set at the slow response throughout, since the level of the sound was steady and realized it did not vary for more than 5 dB (A) (Bruel, 1986).

Questionnaires: Questionnaires were administered to generate information on all possible factors which might act in concert to cause hearing loss and to quantify those at the highest risk of NIHL. For this reason the presence of risk factors such as age, gender, occupation, medical history and non-occupational exposure were included in the questionnaire and their possible impact on the outcome evaluated.

Analysis data: Measurements and survey data were analyzed by using statistical tools, SPSS 16 software. Descriptive statistics were computed for 8hours work shift and t-test was calculated to determine if mean noise level between variables had statistically significant differences. P-values less than 0.05 were considered statistically significant.

Results and Discussion

Noise survey and demarcation of workshops at Anglo Gold Ashanti Limited

Out of the total of 275 workers who participated in the study, 205 were underground miners whilst 70 were surface miners (workshop workers). Their ages ranged from 20 to 55 for underground miners and 20 to 60 years for surface miners (Table 1). Tempest et al, 1985 noted that contributing reasons for the individual susceptibility to NIHL are ages of subjects (Table 2) and occupation types [9].

Table 1. Age distribution of selected underground and surface miners at AngloGold Ashanti Limited, Obuasi.

| Age | No. of miners | |

|---|---|---|

| Underground | Surface | |

| 20-29 | 28 | 15 |

| 30-39 | 79 | 23 |

| 40-49 | 71 | 19 |

| 50 + | 27 | 13 |

| Total | 205 | 70 |

Table 2. Categorization of miners according to years of service.

| Years | No. of miners |

|---|---|

| 1-10 | 41 |

| 11-20 | 105 |

| 21-30 | 98 |

| 31-40 | 31 |

| Total | 275 |

Operational shafts

The operating shafts at the AngloGold Ashanti consist of four functioning shafts each of which boost of all the activity areas. For the purpose of analysis, Surface General (SUR-G) which comprises of workshops and the processing plants were also considered an operating shaft.

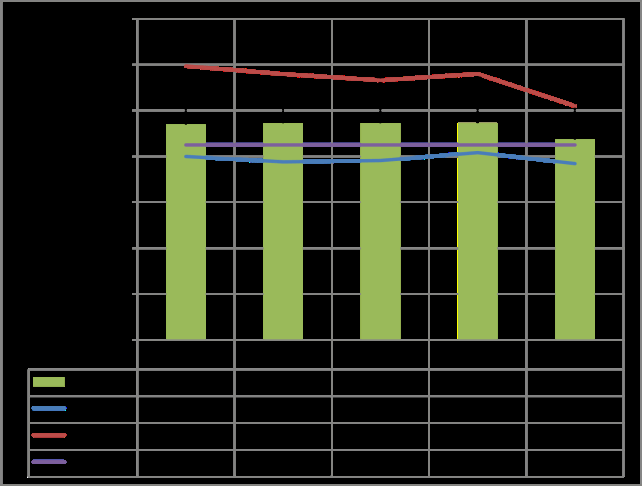

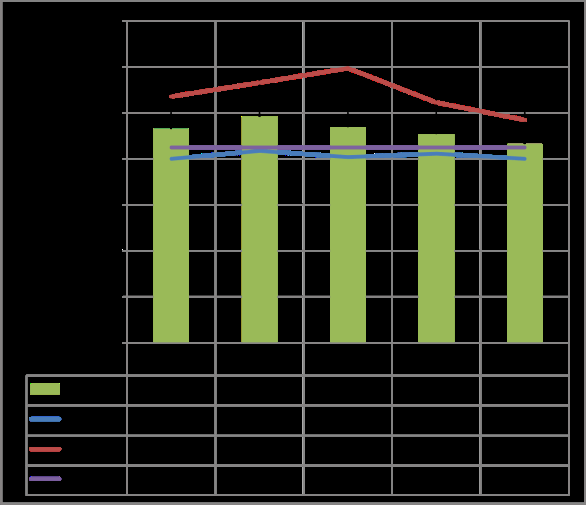

FIG. 1 indicates that, the operating shaft with highest minimum noise level was that of KMS whilst SUR-G recorded the lowest minimum noise level of 76.9 dB (A). The average SPL emitted from all the operating shafts was above the NIOSH REL of 85 dB (A), which may be considered hazardous. This result was consistent with the work of 20. As expected, it appeared that, the maximum values of noise exposure for the operating shafts were similar except for SUR-G which had the lowest of 101.98 dB (A). There is no statistically significant difference between the mean maximum (Lmax) noise levels from the operational shafts and the ACGIH recommended limit of 115 dB (A) (t-test, P<0.05) [10].

Occupationtypes

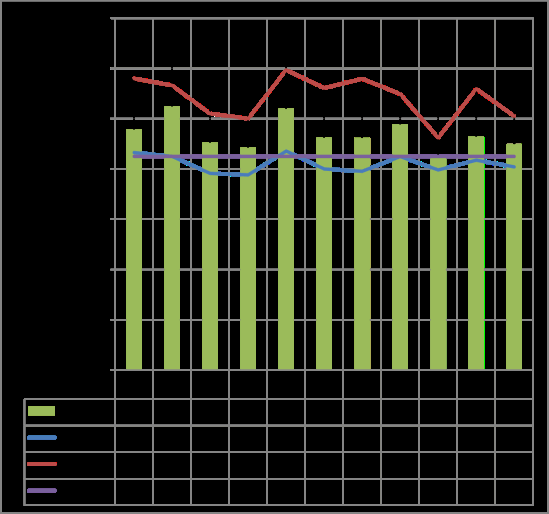

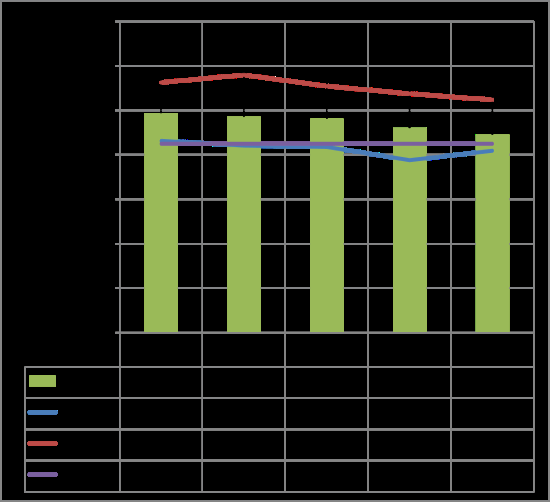

FIG. 2 and FIG. 3 represent the noise levels obtained from the eighteen (18) different occupation types found underground and on surface, respectfully in FIG. 2 and FIG. 3. In comparing the minimum mean levels to the NIOSH Recommended Exposure Limit (REL) of 85 dB (A) for occupational noise exposure for 8 hours average SPL, the mean minimum for Driller (DR) and Blast man (BT) were slightly above the standard by 1.5 dB (A) (less than 2%) and 2.1 dB (A) (about 2.4%) respectively. The mean minimum for Machine Operator (MO) was found equal to the standard. The mean minimum noise levels of Loco Drivers (LD), Welders (WD), Supervisor (SUP) and Headman (HD) were determined to be similar However, only electrician (UE) had a mean slightly above (i.e. less than 1% ) the NIOSH REL of 85 dB (A).

Furthermore, 3 (27.3%) noise levels exceeded the American Conference of Governance Industrial Hygienists (ACGIH) recommended Threshold Limit Values (TLVs) for maximum level of 115 dB (A). The highest maximum level of 119.4 dB (A) was recorded by Blast man (BT) with electrician (UE) recording the lowest maximum of 92.4 dB (A).

The comparison of the mean SPLs (LAeq.8hrs) from the underground occupational types with the standard showed a statistically significant difference (t-test, P<0.05).

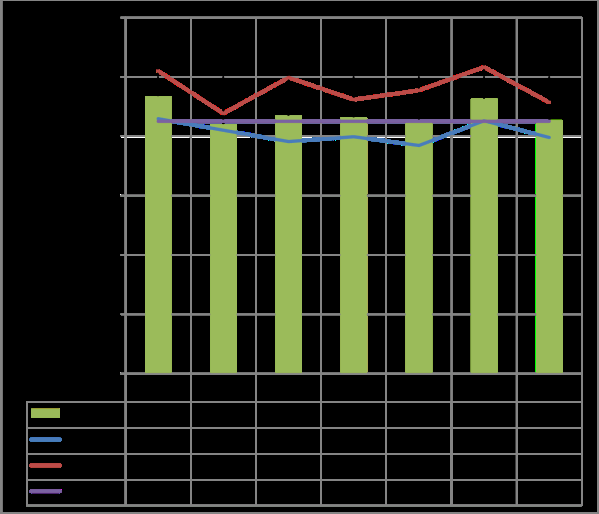

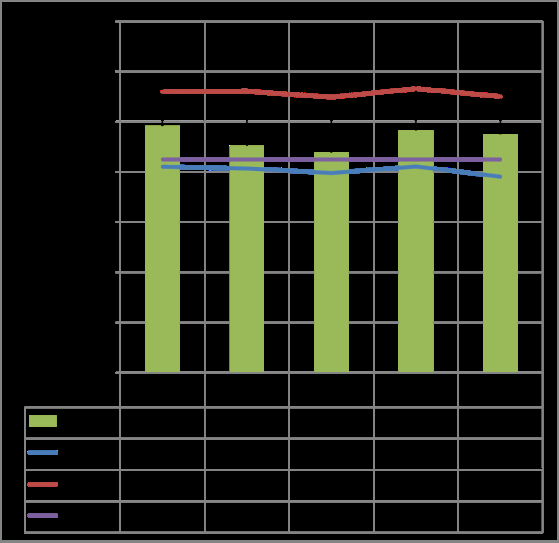

Results on the minimum, maximum and mean SPL of surface miners are shown in FIG. 3. Generally, all the occupational types were susceptible to noise levels which were potentially harmful, however, Drillers (DR), Machine Operators (MO), Blast men (BT), Carpenters (CAR) and STP workers were especially susceptible to noise levels which are potentially harmful since their minimum noise levels exceed the recommended standard of 85 dB (A).

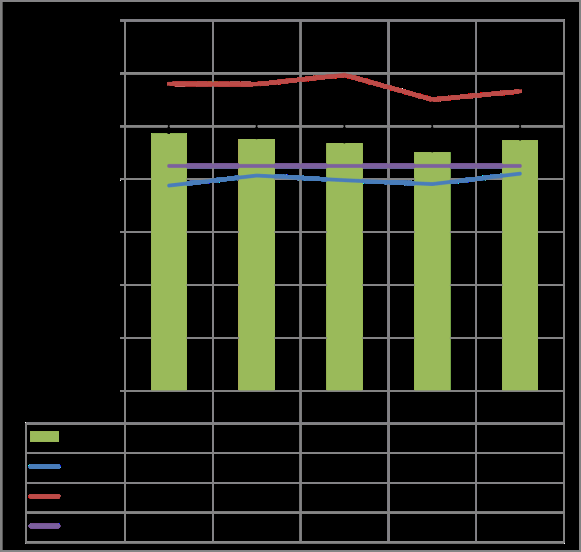

Noise prolife levels of activity areas

The minimum noise levels obtained from all the activity areas were below 85 dB (A). The highest minimum noise level was obtained by Shaft and Service (S and S) recording 82.1 dB (A). This value was not significantly different from the value of 77.6 dB (A) recorded for Development (DEV) which was also the lowest minimum sound pressure level. The highest mean of 97.13 dB (A) (14%>85%) was obtained by Development (DEV) with the lowest of 90.14 dB (A) (6%>85) being the mean value observed for Underground Roving (UR). The comparison of the means from the activity areas with the standard did not show a statistically significant difference (t-test, P<0.05) (FIG 4).

FIG. 4. Mine wide activity areas personal noise exposure profile.

Noise levels from the various shafts within the Anglo Gold Ashanti

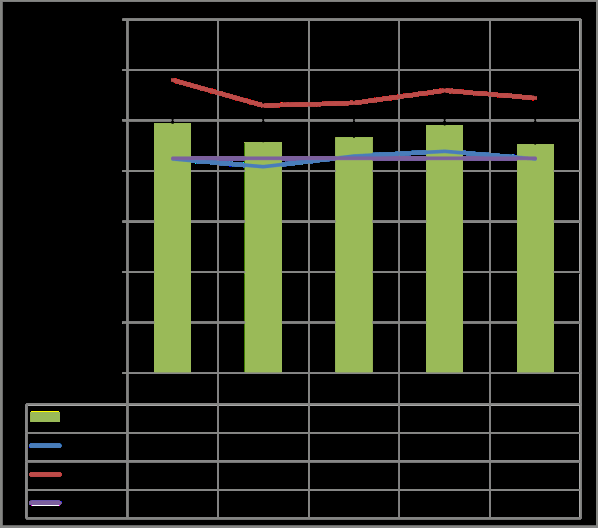

FIG. 5 to FIG. 8 presents the respective SPLs for the different activity areas in each operating shaft. With reference to the mean, the noisiest activity area was stope (98.24 ± 7.27 dB (A)) and the quietest area was shaft and service (86.38 ± 6.37 dB (A)). Only (20%) measurement exceeded the ACGIH recommended limit TLVs for maximum level 115 dB (A)) as shown in FIG. 5. There was no statistical significant difference between mean maximum values and the standard of 115 dB (A) (t. test P<0.05). It shows Development (DEV) recorded the highest mean minimum of 86.3 dB (A) which was a little above 85 dB (A). The difference was not statistically significant. All the mean values from the respective activity areas in Sansu did exceed levels of TWA of 85 dB (A) which may be considered hazardous. The comparison of the means from the Sansu shafts with the standard did show a statistically significant different (P value= 0.006). Again the average sound pressure level (LAeq.8hrs) based on the activity areas in GCS varies from 87.7 dB (A) to 98.3 dB (A). The highest noise area was Development (98.3 ± 8.5 dB (A)) with Haulage (HL) which was slightly above the accepTable limit by 3.2% being the least noise area recording the lowest mean of 87.7 dB (A). The LAeq.8hrs of the noise dosimeter measurements indicated statistically significant difference of LAeq.8hrs exceeding 85 dB (A) (t-test, P<0.05). The results indicate that the maximum values differ according to the activity area. Development (DEV) recorded the highest maximum value which is also slightly above the recommended maximum limit of 115 dB (A). This was closely followed by Underground Roving (UR) with Stope (ST) obtaining the lowest maximum of 105.9 dB (A). In general, 20% measurements exceeded the ACGIH Recommended limit TLVs for maximum level 115 dB (A). The comparison of the mean maximum noise levels from the activity areas at KMS with the standard did show a statistically significant difference (P=0.002).

The incidence of tinnitus

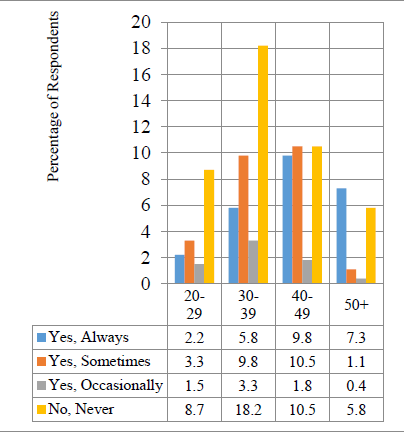

For the purpose of the study, the answers ‘yes always’, ‘yes sometimes’ and ‘yes occasionally’ all mean that the subject suffers from the effects of tinnitus. Therefore the results from these categories must be added together to ascertain the incidence of tinnitus among the study population. Working on this assertion, FIG. 9 illustrates that tinnitus was present in 48 of miners below 50 years old, while in subjects over 50 years of age the incidence was 8.8%.

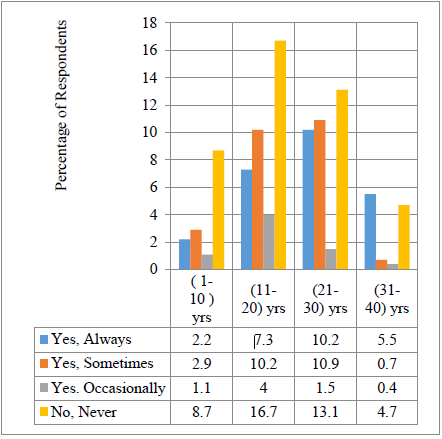

From FIG. 10 workers with years of service between 21 and 30 years had the highest symptoms of tinnitus namely 22.2%. It was observed that the group with up to ten (10) years had an incidence of 6.2% and in the group with exposure for 11-30 years it was 44.1%.

FIG. 9. Age and the prevalence of tinnitus mining workers.

FIG. 10. Years of service and prevalence of tinnitus in gold.

Conclusion

The study achieved its aims of examining the magnitude of noise pollution and to determine the symptoms of NIHL among the miners at Anglo Gold Ashanti, Obuasi. The study shows that miners working underground and in all the operating shafts appear to have been substantially over exposed to noise levels above 85 dB (A). The most critical exposure was the average level of sound emitted from equipment such as the compressors, drilling machines, crushers, auxiliary fans and other mechanical machines.

Sound Pressure Levels from all the operating shafts (Adansi, Sansu, GCS and KMS) were similar. Development and Stope ends were observed to be the noisiest activity areas whilst underground roving was the quietest in the mines. Based on the questionnaires results, majority of the miners (i.e. 56.8%) experienced symptoms of Noise Induced Hearing Loss (NIHL).

The control of noise particularly in underground and the various workshops are highly recommended through the implementation of engineering noise control, administrative noise control or the use of hearing protection devices. Hearing conservation programme should be established to prevent the risk of NIHL. The setting up of a database for all workers and the records of their pre-employment hearing thresholds, their annual hearing screening and any further diagnostic audiology testing would also be a helpful tool in controlling the hearing conservation programmes.

Acknowlegement

The authors acknowledge the logistical supports provided by the Anglo Gold Ashanti Obuasi. Special thanks to the workers of safety departments.

References

- Mirza R, Kirchner B, Dobie RA, et al. Occupational noise-induced hearing loss. Occup Enviro Med. 2018;60:498-501.

[Crossref] [Google Scholar] [Indexed]

- Kerr MJ, Nitzel R, Hong O, et al. Historical review of efforts to reduce noise-induced hearing loss in the United States. Am J Ind Med. 2017;60:569-77.

[Crossref] [Google Scholar] [Indexed]

- Kryter KD. The effect of noise on man. Academic Press, London. 1998: 2nd

- Henderson D, Saunder S. Acquisition of noise-induced hearing loss by railway workers. Ear&Hearing. 1998;19(2):120-130.

[Crossref] [Google Scholar] [Indexed]

- Cristell M, Henderson KM, Alessio HM. Effects of exercise training on hearing ability, Scandinavian Audiology.1998;27(4):219-224.

- Boettcher FA, Henderson D, Gratton MA, et al. Synergistic Interactions of Noise and other ototraumatic agents. Ear&Hearing.1987;8(4):192-211.

[Crossref] [Google Scholar] [Indexed]

- Virokanas H, Anttonan H. Dose-Response relationship between smoking and impairment of hearing acuity in workers to noise. Scandinavian Audiology.1995;24(4):211-216.

[Crossref] [Google Scholar] [Indexed]

- Melnick W. Industrial Hearing Conservation. In Katz, J. (Ed.) Handbook on Clinical Audiology. 4th edition, Baltimore.1994.

- Tempest W. Noise and Hearing. Academic Press Line, London. 1985.

- Medofu KG. Hearing-impairment among workers in a surface gold mining company in Ghana. African Journal of Health Sciences.2002;9(1-2):91–7.

[Crossref] [Google Scholar] [Indexed]