Review

, Volume: 20( 1)Microfiber Pollution: An Emerging Environmental Concern from Textile Sector

Iftakharul Muhib1*, Humaun Kabir2, S.M. Farhana Iqbal3

1Department of General Education, City University, Dhaka-1216, Bangladesh

2Department of Science, Prime University, 114/116 Mazar Road, Section 1, Mirpur, Dhaka-1216, Bangladesh

3Department of Yarn Engineering, Bangladesh University of Textiles, Dhaka-1208, Bangladesh

- *Correspondence:

- Iftakharul Muhib

Department of General Education, City University, Dhaka-1216, Bangladesh

E-mail: muhibitakhar@gmail.com

Received: November 21, 2023, Manuscript No. TSES-23-120652; Editor assigned: November 24, 2023, PreQC No. TSES-23-120652 (PQ); Reviewed: December 11, 2023, QC No. TSES-23-120652; Revised: January 21, 2024, Manuscript No. TSES-23-120652 (R); Published: January 30, 2024, DOI: 10.37532/environmental-science.2024.20.280

Citation: Muhib I, Kabir H, Iqbal SMF. Microfiber Pollution: An Emerging Environmental Concern from Textile Sector. Environ Sci Ind J. 2024;20(1):280.

Abstract

One of the most current dangers to sustainability is Microfiber (MF) contamination. The amount of micro plastic fiber released into the environment has rapidly expanded as a result of the increased use of synthetic textiles. In order to discover viable preventive methods to control MF contamination, this study will assess the body of available literature. The evaluation combines the information under the categori es of textile characteristics and laundry products. The review's findings demonstrate that less MF shedding occurs when finer count yarns with filaments and compact structures are used. Similar to this, mechanical finishing techniques like lifting and shea ring accelerate the release of MFs while harming the fabric's structure. The percentage of MFs reduced is seen to have increased significantly after the chemical (coating) finishing procedure. According to reports, external laundry filters are more effecti ve than in drum devices on the market for commercial items. Few nations have created their own legislation, according to an examination of the regulatory requirements in place, and there were no international standards or procedures for testing MF pollutio n. Laundry filters, while they successfully filter MF, do not stop it from happening, hence they can only be used as a control measure rather than a fix. The review's findings showed that the only method for preventing MF shedding from synthetic textiles i s to manage the textile parameter. A textile that sheds less or no MF will result from using the right production techniques and parameters. There aren't any in depth studies that link these factors together or suggest a suitable area for further study, though.

Keywords

Microfiber Yarn Laundry Fabrics Textile industry Environmental pollution

Introduction

MFs are minute plastic threads that are found in many different textiles, such as clothing, tires, fishing nets, cigarette butts, floor mats, ties, and lace, and have a diameter of less than 5 mm. They are found throughout the environment [1]. Due to their significant contribution to environmental micro plastics, these contaminants are raising concerns. These are used to create a wide range of goods that are essential to human existence, including fabrics, ropes, household plastic bottles, and many more. Synthetic MFs are now recognized as anthropogenic waste and have been found in all environmental matrices, including air, soil, rivers, lakes, and seas [2]. Microplastic pieces discharged from home sewage contaminated by synthetic garments from residential washing machines have been freshly identified as the latest and most alarming cause of marine pollution [3]. Over the past two to three decades, the production and consumption of clothing have significantly expanded in major cities due to the numerous benefits of synthetic fiber [4]. Due to their strength, softness, stain resistance, and important cost element, these Synthetic Fibers (SF) have overpowered natural fibers and seized the apparel sectors on the global market. We all wear various synthetic clothes, such as jackets, yoga pants, socks, underwear, and blankets, every day without thinking about their disposal. From the universal production of fabric, 60% of synthetic fibers are produced, natural fabric accounts for about 30%, and 10% accounts for other materials. Of the total synthetic fabric production, only polyester accounts for more than 50% of the worldwide fiber market. It is estimated that polyester is a dominant synthetic fiber in the global fiber market, and its production rate has been augmented tremendously from 5 MT in 1980 to 50 MT in 2017 [5]. Despite being made from natural sources, semisynthetic fibers are chemically processed and extruded into filaments in the same way that synthetic fibers are. Natural fibers, on the other hand, are not extruded and retain their morphological properties. Natural fibers have been utilized for thousands of years and are now widely employed in textile production, as well as personal care items such as wet wipes [6]. Because natural fibers come from a variety of sources, they are frequently classed as cellulosic (plant-based, e.g., cotton), proteinaceous (animal-based, e.g., wool), or mineral (Figure 1). Despite the fact that fabric contaminants are found in rivers, lakes, and ocean waters all over the world, the area of environmental studies has only recently identified them as a major source of worry. This review paper exhaustively describes the source of MFs, the impact of substantial MF contamination on environmental pollution, exposure to marine creatures and humans, probable causes of MF toxicity, and remediation efforts. The future research prospects for detection, characterization, and remediation have been proposed.

Literature Review

Global MF pollution

China alone accounts for 70% of the global output of synthetic fiber, which is produced by 80-85% of Asian nations [7]. According to a commercial research published by the global apparel fiber consumption survey, consumption of synthetic apparel has surged by almost 65% globally. Two of the main aspects of synthetic MF pollution worldwide are the manufacture and consumption of synthetic fibers. According to reports, synthetic clothing accounts for 20 to 35 percent of the plastic debris found in aquatic environments [8]. All across the world, seashores contain these fibers, which are primarily made of microplastic trash [9]. The prevalent types of MFs were polyester, nylon, and polystyrene (Table 1).

| S.N. | Country | Production Mt/year | Major contributory sources | Dominant MFs |

|---|---|---|---|---|

| 1 | China | 9.17 | Laundry, plastic bags, the textile industry, and plastic items | Polyethylene, polystyrene, and polypropylene |

| 2 | Indonesia | 3.5 | Clothing industry, laundry | Polystyrene |

| 3 | USA | 3 | washing of all synthetic clothing types | Polyester |

| 4 | Sri Lanka | 2 | Industry of textiles, laundering | Polyester |

| 5 | India | 0.5 | Clothing, personal care items, and tires | Polyester, Nylon |

| 6 | Europe and Central Asia |

0.24 | Industry of textiles, laundering | Polyester, polyamide and acrylic |

| 7 | East Asia and Oceania |

0.23 | Domestic cleaning and tire abrasion | Polyethylene, polypropylene |

| 8 | Africa | 0.13 | textiles | Polyester |

TABLE 1. Major MF polluting countries.

Domestic and commercial laundry, tire abrasion, illegal land filling, wastewater treatment plants, and a very limited quantity of sea-based sources all produce MF particles. Although fundamental sources have not yet been investigated, household laundry wastewater is widely believed to be the most significant source. Approximately 730,000 MFs are thought to be released by a single synthetic clothing during a single laundry wash [10]. All improperly treated MFs are transported mostly along rivers, where they eventually find their way into the ocean. Today, all oceanic matrices, including shorelines, surface water, and deep sediments, have been found to contain these types of fibers. According to Tiwari et al., polyester is the most prevalent MF in the shoreline of Indian coastal areas, which spans from 5-36 mm [11]. The synthetic MFs, which ranged in diameter from 10 to 22 m and were found in Admiralty Bay, Antarctica's ocean surface water, were recognized by their chemical compositions, the majority of which were microplastics and SMFs [12]. In the Southern European deep sea sediments, Sanchez-Vidal et al., found microplastic polymers such PE, PP, PA, and acrylic in abundance with 10-70 MFs per 50 ml [13]. The ubiquity of synthetic MFs in the atmosphere is causing growing environmental and human health concerns. For the quick identification and characterization of these expanding environmental micro pollutants, consistent approaches are needed. Recently, Fourier Transform Infrared (FTIR) and Raman spectroscopic techniques have been developed for automatic and rapid detection of these particles. Similarly, surface morphology characterization investigations of MFs using Scanning Electron Microscopy (SEM) have been described [14].

Influence of textile characteristics on MF shedding

Textile fabrics have been identified as a major source of MF emissions. Numerous research articles have been published on MF creation during various stages of its lifecycle, such as manufacturing, usage, and disposal. The wet processing phases of manufacture were found to have the highest MF shedding. The stronger the physical agitation, mechanical stress, and chemical treatments used in wet processing steps such as bleaching, dyeing, and finishing, the more MF is released into the wastewater. Even after effluent treatment, researchers found a considerable proportion of MF [15]. According to the second researcher, around 60% of the fibers identified in the treatment site are synthetic textile MFs. Similarly, more mechanical stress is applied during the user phase throughout the wearing and laundering procedures. It is commonly known that the laundering procedure causes 90% of textile degradation. The usage of various machines and washing aids contributed significantly to MF contamination [16]. Air quality investigation from the atmosphere revealed considerable MF contamination in numerous regions dependent on clothing type and population density [17]. Figure 2 shows the many stages of textile development and how they affect MF pollution. The cloth degrades over time and breaks down into microscopic and nanoscale particles during the disposal phase. This trash pollutes the air, water, and land and spreads throughout all themes.

According to a recent study, the fabric cutting technique affects the amount of MFs that shed throughout the laundering process. The researchers contrasted various cutting techniques, such as laser cutting and scissor cutting, with various stitching techniques, such as double-fold sewing and overlock sewing. Due to mechanical damage they sustained during the cutting process, the scissor-cut samples released more MF than the laser-cut ones, according to the data. The edge-sewing techniques also did not demonstrate a decrease in MF release. Results from samples that were overlocked stitched revealed a higher release than the raw edge. Around 84% of the MF is released from the edge of the fabric, according to the researchers, who also determined that edge release is greater than surface release [18]. A finer-count filament with a higher tenacity will lower the MF release compared to a bulkier filament or traditional yarn, according to research findings. Shedding behavior is significantly influenced by the type of yarn used in production. For reduced MF shedding, a tight yarn structure with a higher twist and an even surface with less hairiness is desirable. Similar to this, choosing woven fabric over knit fabric with flexible structures results in less MF shedding. To obtain lesser shedding qualities, fibers with higher tenacity and elongation are also necessary. Furthermore, it is significant to note that compared to fresh and virgin synthetic textiles, recycled and used materials shed more fibers [19]. To make the textile process sequences a cleaner production procedure, the aforementioned points must be taken into account. To lessen the impact, it is also crucial to inform the market and consumers about the many types of raw materials, fabric structures, and finishes stated. However, each person and manufacturer should prioritize the need for change over their financial goals and advantages.

Surface finishing's impact on MF Sheddin

As a preventive approach, textile surface alterations may assist in resolving the problem from the ground up. The Mermaid-Ocean Clean Wash Report conducted the initial investigation on MF reduction utilizing the textile finishing process. In order to prevent MFs from escaping from textile structures, the report demonstrated the application of textile auxiliaries as a finish on textiles. As finishing materials, padding and exhaustion techniques were utilized with acrylic resins, PU resins, silicone emulsion, and acid-based enzymes [20]. With woven or knitted polyester, polypropylene, acrylic, and polyamide fiber, the shedding behavior was calculated using pilling and washing experiments. According to the findings, the acrylic resins outperformed the other auxiliaries in terms of pilling resistance with all the fabrics. The application of a pectin-based finish as a protective coating to lessen MF shedding from the polyamide fabric was recently studied by another researcher. Pectin was chosen because of its capacity to interact with fabrics and because it is readily available, sustainable, and abundant. The pectin is first given glycidyl methacrylate treatment to produce a composite emulsion, and the pectin-glycidyl methacrylate emulsion is subsequently grafted onto the polyamide fabric. The washing procedure was used to gauge how much MF was released from the finished and control fabrics. The results showed that the pectin-finished fabric released MF with an average length and diameter of 550 ± 384 μm and 16 ± 4 μm, respectively, as opposed to the control polyamide fabric, which had a MF release with a length of 12 ± 222 μm and a mean diameter of 18 ± 3 μm.

Filtration systems' impact on MF shedding

Laundry causes more harm than any other process, including manufacturing and use, to textile materials. Looking for solutions in the laundry process will be an efficient way to reduce MF emissions because shedding is related to fiber damage, and laundry produces additional damage. There are numerous commercially available technologies for removing MFs from residential wash water. Both external filters and in-drum filters are included in this group.

Techniques for extracting MFs

Numerous difficulties are encountered when studying MFs, some of which are universal to all forms of MFs and others which are unique to non-synthetic fibers. Figure 3 depicts these difficulties in general terms. First, efficient recovery from several environmental matrices (such as surface and subsurface fluids, wastewater influent, and effluent) is particularly difficult due to the size and structure of MFs. MFs may not be efficiently caught by standard microplastic collection techniques as manta trawls or neuston and bongo nets because their smallest dimension has a diameter of about 10 μ to 20 μm. For instance, several studies on the presence of microplastics in surface water have used coarse mesh nets (such as the Manta and Neuston), which are good at detecting bigger particles (300-500 μm), but not MFs. In comparison to previous sampling methods, bulk water included larger amounts of MFs than other particle morphologies. MFs are therefore probably underestimated in investigations that frequently use coarse mesh or sieves.

FIG 3: Overview of the difficulties and ideal procedures for counting and describing environmental MFs.

Impacts of MF on human health

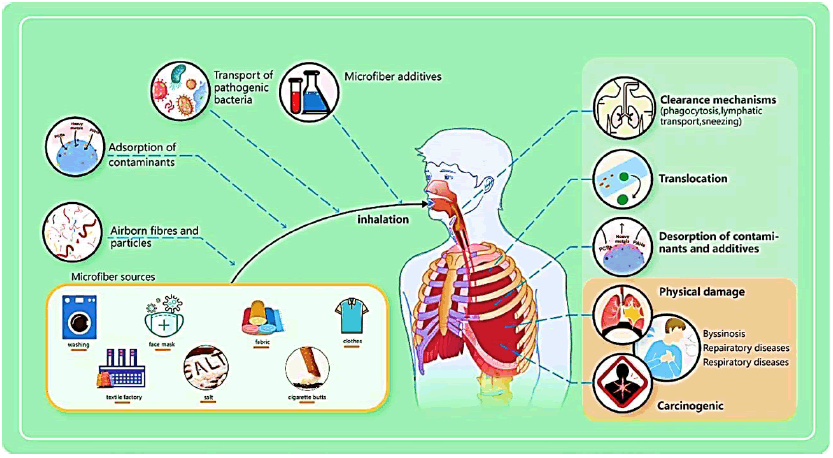

The two primary methods by which people are exposed to MFs on a regular basis are inhalation and ingestion. For inhalation, numerous clinical instances have demonstrated a substantial relationship between MF exposure and the occupational health of textile workers. Byssinosis, respiratory illnesses, allergies, and epithelial development are all negatively impacted by prolonged and high exposure to organic dust comprising hemp and cotton MF through inhalation and skin contact. According to a cross-sectional study conducted in Pakistan, 35.6% of textile workers, particularly those in spinning and weaving mills exposed to greater densities of MF, have byssinosis. Up to 40% of textile workers globally have byssinosis. Byssinosis has been a common occupational disease among textile workers, particularly in low- and middle-income nations. According to Lai and Christiani, 2013, respiratory illnesses, such as restrictive lung diseases and reversible or irreversible obstructive lung disorders (such as asthma or chronic obstructive pulmonary disease), are common among textile workers. When 13 human lungs were obtained following thoracic surgical procedures at Castle Hill Hospital in the United Kingdom, polypropylene and polyethylene terephthalate fibers (≤ 3 μm) were the most frequently found in all locations. In both indoor and outdoor contexts, MFs serve as reservoirs for additive chemical content, volatile and semivolatile organic compounds, bacteria, and fungi, acting as a selective pressure within emerging respiratory and gut microbiomes (Figure 4).

The way forward

It is now challenging for stakeholders and the general public to focus on the management of MF since it is unclear how widespread and abundant as well as how the pollution caused by environmental MFs works. Relevant practitioners have started to concentrate on the issue of microplastic fiber contamination in recent years as a result of increased exposure to microplastic pollution in the media. It should be made clear, nonetheless, that MF does not immediately correspond to microplastic fiber. Sometimes the term "MF" refers to a broader class of substances than just microplastic fiber. Thus, it is essential to research and comprehend the short-, medium-, and long-term mechanisms of MF pollution in order to gradually realize its control in business and daily life.

In addition, MF already have a big effect on environmental pollution, and that effect is only going to get bigger in the next decades. Most of the possible harmful effects of MF on human health remain unclear. That is the fundamental issue, exactly. Since MF pollution is pervasive, it must be addressed before it may develop into a significant problem. Devices to reduce MF release from clothing during washing or to trap MFs released in wastewater are part of the current global strategy to manage MF pollution, however it is failing. All parties involved are urged to carry out their social duties and implement corporate MF pollution reduction plans as part of efforts to mitigate climate change. In order to reduce MF pollution from textiles and clothing, certain practical sustainable solutions are suggested as illustrated in Figure 5. Specifics are covered in the following subsections.

FIG 5: From the viewpoints of manufacturers, customers, retailers, and governments, some practical methods for reducing MF pollution are suggested for the sustainability of textile and fashion as well as environmental preservation.

Discussion

Better yarn quality will control MF pollution at source

While the issue of MF contamination must be addressed across the textile supply chain, from the fibers to the consumer, technical advancement in the textile sector will help to solve the issue at its root. Due to the shedding of yarn hairiness and fluff on clothing at the source, new types of fiber production, innovative design, and production processing of yarn and fabric are important methods to reduce MF release. However, there is very little research on the impact of yarn and fabric properties on MF release. The initial steps to minimizing MF pollution are the development and usage of eco-friendly bio fabrics and sustainable bio-textiles, as well as the use of natural and regenerated fibrous materials for the new trend in the fashion and textile sectors. The primary determinants of shedding resistance are the chemical and physical characteristics of the fiber, including its chemical composition, length, density, surface and cross-sectional form, fineness, tenacity, strength, elongation at break, elasticity, and capacity to resist friction. The characteristics of the yarn and fabric, such as the proportion of different fibers in the blend, the number of hairs per meter, the length of the hairs, the twist and count of the yarn, the repetition of the weave, and the weight of the fabric per square meter, will have a direct impact on how well the fabric resists pilling and abrasion.

According to Carney Almroth et al., fleece textiles and staple yarns are likely the main contributors of microfibre during laundry. Effective ways to prevent MF shedding include increasing abrasion resistance and reducing yarn pilling and fuzzing, which can help reduce MF shedding released into laundry water. Increasing the life cycle and decreasing MF shedding also require lowering pilling and abrasion in everyday use. Innovative anti-MF-shedding techniques, like functional finishing and coating for fleece and underwear to stop MF release from knitted fabric used as a base, will result in clothing that is just as warm without having a negative environmental impact. This shows that the best ways to reduce MF emissions are through changes made to the characteristics of fiber, yarn, and fabric during the design and production phases.

From the material source to end-of-life recycling, fashion brands' involvement at the fiber selection, yarn spinning, and fabric design phases can significantly increase sustainability. The problem of MF contamination is addressed by a number of players in the fashion supply chain, including manufacturers of fiber, yarn, fabric, and apparel as well as retailers and fashion brands. The resources and waste plan should include eco-design concepts and provide incentives for recycling, disassembly, and durability designs in some developing nations that serve as the primary producers and exporters of textiles and apparel. In order to promote the use of recycled fibers in developing nations where the manufacture and export of textiles and clothing are the primary businesses, it should also establish a new investment fund. The good news is that some companies are stepping up to fund the research on MF release, which will lead to the development of some fresh strategies to lessen microfibre shed at sources.

A global contract with legal effect

At the fifth summit of the United Nations Environment Assembly (UNEA), which took place in February 2021, numerous states suggested an international accord to address plastic pollution. At the UNEA5.2 on March 2, 2022, a draft resolution on a worldwide commitment to decrease the discharge of plastics across the plastic life cycle will be discussed. A historic move and a step forward for humanity would be a legally binding international agreement to effectively stop the growing problem of plastic pollution. Even though more than 35% of microplastics are fibers from textiles, the agreement did not specifically address MF pollution as an issue with plastic pollution. If textile-derived microplastics are included in the draft resolution that will be further discussed inside the UNEA5.2 frameworks in 2024, immediate action against plastic and microplastic pollution will be enhanced in a wider context with more comprehensive and long-term solutions.

MF pollution legislation

As of February 2020, all newly sold washing machines must have a MF filter installed by the year 2025, as required by French law. France is the first nation in the world to implement legislation to prevent and regulate MF pollution from laundry. France's experience demonstrates that laws can be used to control MF pollution. Although contentious, France's regulation on MF contamination offers a workable solution to the serious ecological and environmental issue. It is expected that laws governing MF contamination would be more broadly enacted. The waste and wastewater generated in the pertinent industrial production processes, rather than household laundry, is the most significant source of MFs in the environment, as was covered in earlier sections. Future legislation must therefore concentrate on instances of MF emission in industrial manufacturing. From a technological standpoint, the MF discharge needs to be evaluated quantitatively and laminated.

Formation of MF pollution technical standards

To address MF contamination, some voluntary, consensus-based, or statutory standards pertaining to microplastics from textile sources will be created. The development of three technical standards on microplastics from end-textile products was approved in 2022 by the ISO/TC 38 subcommittees responsible for sampling, measuring, and evaluating material loss for MFs from textile end-products by domestic washing methods. The adoption of quantitative measurement and evaluation standards for microplastics originating from textile sources will hasten the innovation of yarn and fiber production as well as the advancement of clothing and fabric design. Throughout the entire lifecycle of a fibrous material, a wide range of stakeholders in the textile and apparel supply chain, including but not limited to the textile and fashion industry and washing machine makers, search for and promote solutions. The design and manufacture, reuse, recycling, disposal, and retrieval of textiles and clothing will be governed by a number of technical standards and guidelines that will be updated and released at various levels in the future.

Using the circular economy to combat MF pollution

Only 15% of the textiles consumed annually around the world in the past 20 years have been recycled, despite this. A significant quantity of textile waste is directly related to the disposable character of fast fashion and "throwaway culture" in the Asian economy. However, this causes a significant loss of important resources as well as an ever-growing environmental issue. A novel strategy for cutting down on textile waste and minimizing MF pollution is the circular textile economy. In comparison to more conventional techniques like landfilling and cremation, reuse and recycling may generally keep fibrous materials at their best value and minimize environmental damage. More advantageous than recycling is the reuse of worn-out but still wearable clothing, such as cotton clothing and fashion made of synthetic fibers that doesn't age. A circular textile economy will encourage and start the adjustment of the textile value chain from the standpoint of sustainable development, especially for several key textile and clothing producing nations in Asia and Africa. The development of next-generation fibrous material design will be influenced by environmental and ecological considerations, which will raise the end-of-life value of these materials over time.

Conclusion

MFs have been identified as an emergent environmental pollutant on a global scale, according to this review. To satisfy the sustainability demands of the textile and fashion industries, thorough study on their probable sources and the creation of joint strategies to manage MF contamination at various stages are essential and important. To halt MF pollution at its source, systemic solutions utilizing tactical and strategic interventions are needed, and bold actions from a wide range of stakeholders are necessary across the whole lifecycle of fibrous materials to implement these interventions. A systematic research is underway to determine how to inform a multi-industry approach to address MF contamination at many scales, including fiber, yarn, and textile producers, fashion labels, washer manufacturers, consumers, retailers, wastewater treatment plants, and the government.

A successful strategy for reducing MF pollution is to make progress in addressing the sources of fiber shedding throughout the entire textile and fashion lifecycle. From the material source to end-of-life recycling, fashion brands' involvement at the fiber selection, yarn spinning, and fabric design phases can significantly increase sustainability. The switch from fast fashion to slow fashion will directly reduce the amount of clothing and textiles disposed of and reduce MF emissions during laundering. Retailer recycling initiatives will lessen the damaging effects of worn clothing and textiles on the environment and promote the transition to a circular economy in order to build a more sustainable sector of the economy. Collaboration will play a major role in addressing the issue of MF pollution and the sustainability requirements of the textile and fashion industries at all levels, from individuals to the entire supply chain of these businesses.

Acknowledgment

The authors would like to thank all the writers who have contributed in the field of MF pollution.

Authors Contributions

Conceptualizing, writing original draft, SMFI and MHK; Editing, Writing, MIM; Writing, Editing, Supervising, MHKR

Conflict of Interest

The authors declare that they don’t have any conflict of interests.

References

- Absher TM, Ferreira SL, Kern Y, et al. Incidence and identification of microfibers in ocean waters in Admiralty Bay, Antarctica. Environ Sci Pollut Res Int. 2019;26:292-298.

[Crossref] [Google Scholar] [PubMed]

- Athey SN, Erdle LM. Are we underestimating anthropogenic microfiber pollution? A critical review of occurrence, methods, and reporting. Environ Toxicol Chem. 2022;41(4):822-37.

[Crossref] [Google Scholar] [PubMed]

- Belzagui F, Buscio V, Gutierrez-Bouzan C, et al. Cigarette butts as a microfiber source with a microplastic level of concern. Sci Total Environ. 2021;762:144165.

[Crossref] [Google Scholar] [PubMed]

- Browne MA, Crump P, Niven SJ, et al. Accumulation of microplastic on shorelines woldwide: Sources and sinks. Environ Sci Technol. 2011;45(21):9175-9.

[Crossref] [Google Scholar] [PubMed]

- Bucknall DG. Plastics as a materials system in a circular economy. Philos Trans A Math Phys Eng Sci. 2020;378(2176):20190268.

[Crossref] [Google Scholar] [PubMed]

- Cai Y, Yang T, Mitrano DM, et al. Systematic study of microplastic fiber release from 12 different polyester textiles during washing. Environ Sci Technol. 2020;54(8):4847-4855.

[Crossref] [Google Scholar] [PubMed]

- Cao Y, Qu Y, Guo L. Identifying critical eco-innovation practices in circular supply chain management: Evidence from the textile and clothing industry. Int J Logist Res Appl. 2023;26(11):1462-1483.

- Almroth BMC, Astrom L, Roslund S, et al. Quantifying shedding of synthetic fibers from textiles; a source of microplastics released into the environment. Environ Sci Pollut Res Int. 2018;25:1191-1199.

[Crossref] [Google Scholar] [PubMed]

- Carr SA. Sources and dispersive modes of micro-fibers in the environment. Integr Environ Assess Manag. 2017;13(3):466-469.

[Crossref] [Google Scholar] [PubMed]

- de Falco F, Di Pace E, Cocca M, et al. The contribution of washing processes of synthetic clothes to microplastic pollution. Sci Rep. 2019;9(1):6633.

[Crossref] [Google Scholar] [PubMed]

- de Falco F, Gullo MP, Gentile G, et al. Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environ Pollut. 2018;236:916-925.

[Crossref] [Google Scholar] [PubMed]

- Hartline NL, Bruce NJ, Karba SN, et al. Microfiber masses recovered from conventional machine washing of new or aged garments. Environ Sci Technol. 2016;50(21):11532-11538.

[Crossref] [Google Scholar] [PubMed]

- Henry B, Laitala K, Klepp IG. Microfibres from apparel and home textiles: Prospects for including microplastics in environmental sustainability assessment. Sci Total Environ. 2019;652:483-494.

[Crossref] [Google Scholar] [PubMed]

- Hung C, Klasios N, Zhu X, et al. Methods matter: methods for sampling microplastic and other anthropogenic particles and their implications for monitoring and ecological risk assessment. Integr Environ Assess Manag. 2021;17(1):282-291.

[Crossref] [Google Scholar] [PubMed]

- Hussain N, Kadir MM, Nafees AA, et al. Needs assessment regarding occupational health and safety interventions among textile workers: A qualitative case study in Karachi, Pakistan. J Pak Med Assoc. 2019;69(1):87. [Crossref]

[Google Scholar] [PubMed]

- Jenner LC, Rotchell JM, Bennett RT, et al. Detection of microplastics in human lung tissue using μFTIR spectroscopy. Sci Total Environ. 2022;831:154907.

[Crossref] [Google Scholar] [PubMed]

- Karanikas N, Hasan SM. Occupational Health & Safety and other worker wellbeing areas: Results from labour inspections in the Bangladesh textile industry. Safety Sci. 2022;146:105533.

- Kaya AT, Yurtsever M, Bayraktar SC. Ubiquitous exposure to microfiber pollution in the air. Eur Phys J Plus. 2018;133(11):488.

- Lai PS, Christiani DC. Long-term respiratory health effects in textile workers. Curr Opin Pulm Med. 2013;19(2):152-7.

[Crossref] [Google Scholar] [PubMed]

- Lindeque PK, Cole M, Coppock RL, et al. Are we underestimating microplastic abundance in the marine environment? A comparison of microplastic capture with nets of different mesh-size. Environ Pollut. 2020;265:114721.

[Crossref] [Google Scholar] [PubMed]