Original Article

, Volume: 12( 9)Industrial Business between Environmental Management (ISO 14001: 2015) and the Challenges of Development: The Case of the Industrial Park of Mohammedia City â Morocco

- *Correspondence:

- El Hour

, Laboratory of Biotechnology, Environment and Quality, Faculty of Science, Ibntofail University, PO Box 133, 14000, Kenitra, Morocco, Tel: 212-537374052; E-mail: s.elhour@gmail.com

Received: August 30, 2016; Accepted: September 09, 2016; Published: September 15, 2016

Citation: El Hour S, Aouane M, Chaouch A. Industrial Business between Environmental Management (ISO 14001: 2015) and the Challenges of Development: The Case of the Industrial Park of Mohammedia City ? Morocco. Environ Sci Ind J. 2016;12(9):110.

Abstract

Environmental management designates to the management methods of an entity (enterprise, administration). Indeed, to control the environmental impact of the activity and to ensure compliance with regulations and laws, the production units implement Environmental management system according to the guidelines of the ISO 14001 standard, this standard is based on the principle of continuous improvement of the environmental performance of the company as well the establishment of an environmental approach that enables the company to meet the three key elements of sustainable development. The objective of this scientific paper is to show that the establishment of the environmental management system ISO 14001 allows the units of production in the industrial park of Mohammedia city to respect the environmental approach, to ensure a gain economic and social and therefore face the challenges of development.

Keywords

Environmental management system; ISO 14001; Challenges of development; Unites of production

Introduction

The purpose of ISO 14007: 2015 is to provide organizations with a framework to protect environment and to respond to changing environmental conditions in balance with socio-economic needs. It specifies requirements that enable an organization to achieve the intended outcomes it sets for its environmental management system. Thus, the environmental management is accomplished principally in response to requirement in environmental laws and regulations [1].

A systemic approach to environmental management can provide top management with information to build success over the long term and create options for contributing to sustainable development by [2]:

• Protecting the environment

• Mitigating the potential adverse effect of environmental conditions

• Assisting the organization in the fulfilment of compliance obligations

• Enhancing environmental performance

• Controlling or influencing the way the organizations products and services are designed, manufactured and distributed

• Achieving financial and operational benefits

• Communicating environmental information to relevant interested parties

It is a modern approach remains innovative today; it helps to consider systematically the impact of production activities of the company on the environment. Therefore, it is to integrate environmental approach in the structure and the strategic organization of the company. The Environmental management allows facing the development challenges: it helps in the process of continuous improvement of the company by integrating economic evolution with environmental assurance, social development and technical progress to ensure the global continuous improvement. Hence, it is essential to take action to remove, even reduce the negative effects [3], and to adopt an environmental policy, whether this company is large or small, are also committed firmly in this direction [4]. And without ignoring that on the environmental approach to business organization is still subject too regulatory, institutional and administrative pressures. The target of our scientific research is to show the importance and the vital and indispensable role of environmental management in the development process.

Principles of Environmental Policy

Top management shall establish, implement and maintain an environmental policy that, within the defined scope of its environmental management system:

a) It is appropriate to the purpose and context of the organization, including the nature, scale and environmental impacts of its activities, products and services.

b) Provides a framework for setting environmental objectives;

c) includes a commitment to the protection of the environment, including prevention of pollution and other specific commitment(s) relevant to the context of the organization;

d) includes a commitment to fulfil its compliance obligations;

e) Includes a commitment to continual improvement of the environmental management system to enhance environmental performance. The environmental policy shall - be maintained as documented information; - be communicated within the organization; - be available to interested parties.

The environmental policy is the set of procedures developed by the company in an objective to contribute in the approach to development and continuous improvement unit of production. It is a policy of environmental management system (EMS) required by the guidelines of the ISO 14001 standard. The international standard ISO 14001 defines EMS as "a component of the management system of an organization used to develop and implement its environmental policy and manage its environmental aspects. This system includes organizational structure, planning activities, responsibilities, practices, procedures, processes and resources".

The EMS has undergone several discussions about the studies were primarily interested:

• For reasons that favor production units to adopt this system based on research and studies.

• In the contingency factors that may influence its implementation in companies.

• In the impacts and effects, it could have on the continuous improvement environmental approach to business.

In practice, the environmental management system (EMS) developed based on the requirements in ISO 14001 that it considered the benchmark in the matter. The latter was the subject of numerous research studies which, case studies in support, have described the principles and highlighted the advantages and limitations.

ISO 14001 is an international standard that describes the principles and requirements of the EMS, it specifies requirements for an environmental management system to enable an organization to develop and implementer an approach and objectives which take into account the legal guidelines and other directives to which the organization subscribes, and information about significant environmental impacts. It applies to those environmental aspects that the organization identifies as those it has the means to control and influence.

ISO 14001 is based on the objective of driving environmental performance by controlling the impacts related to the activity of the company, in the same approach it should be noted that respect for regulatory devices is always present in environmental policy that can adopt. Thus, every business needs to know the requirements of the regulations, industry codes, standards and permits that must be respected. Organizational systems are needed to ensure compliance, appropriate monitoring and possibly prepare reports [5]. In the same context, it is imperative that each company’s compliance with legal requirements and other requirements to establish its environmental objectives and targets to develop its programs [6].

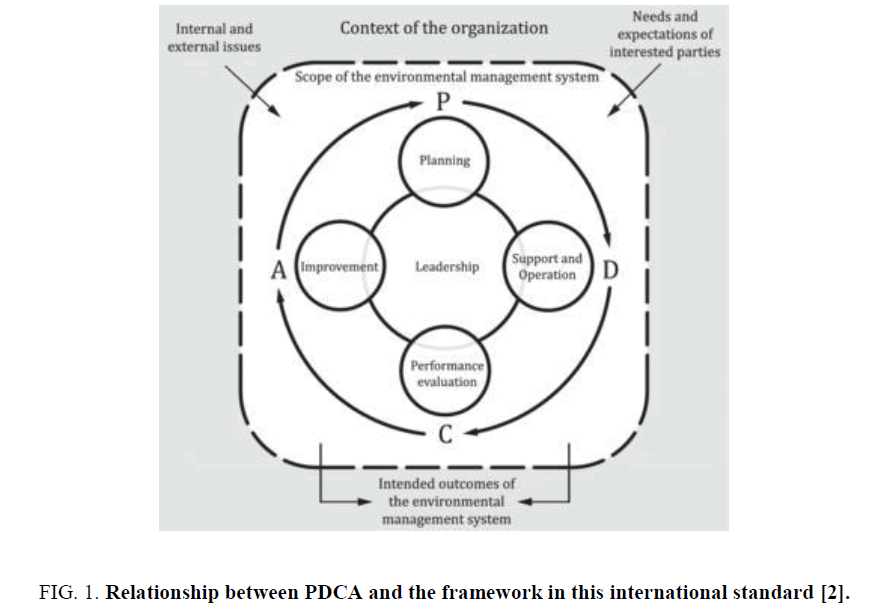

ISO 14001 requirements continent a whole of requirements, in totally points, organized according to the methodology of PDCA, it allows managing the process of implementation of an environmental management system.

The standard comprises, in Chapter 4 "EMS Requirements" requirements in five sections as shown in (Figure 1):

• Requirement 1: 5.1 Environmental Policy: it describes the objectives and principles of environmental performance, that environmental politics was once considered “low politics" in international relations [7].

• Requirement 2: A.6 Planning (plan): Know your significant environmental impacts through a detailed inventory and set goals and targets to improve environmental performance in line with its policy, and implement a plan of action to achieve its objectives and implement environmental policy. Planning is a fundamental function of management. It consists of selecting strategies from among alternative courses of action., planning is, in effect, deciding in advance "what to do", "how to do it”, "when to do it" and "who is to do it". Planning assumes that rational processes can be used to nominate resources and define appropriate future actions, which will produce the desired outcomes [8].

• Requirement 3: 4.4 Implementation and operation (do): Developing methods to carry out the action program developed taking into account, in particular, normal and abnormal operating situations, from the perspective of stakeholders involved, the technical capacity human and financial of the company.

• Requirement 4: A.8.1 Control (check): controller and evaluate results and progress achieved in the prevention of pollution and continuously monitor the effectiveness of the environmental management system.

• Requirement 5: A.9.3 Management Review (Act): Bring together the top management team and coaching concerned to monitor the EMS and target lines and components for improvement particularly in the light of the test results. And be able to adapt to changes in circumstances.

This approach considerate as a basis for the integration of environmental objectives in the company's management, in this context it is defined as a tool of development and continuous improvement the company. The development and continuous improvement of long-term production units will measure if there is a positive economic return. A question of economic gain allows public authorities to preserve nature and save the available resources on the planet. This mode of development requires reflection on environmental inequality and climate change.

The summary of the study of EMS and ISO 14001 has shown that the implementation of EMS according to the guidelines of ISO 14001 in companies ensures the continuous improvement of the environmental performance of these and that process is a tool for development and continuous improvement.

Our present scientific research assesses these parameters based on the results of an experimental study carried out in production units involved in its EMS certification process according to ISO 14001: 2004 for the sake of demonstrating environmental and to ensure a healthy, safe environment commitment. This is what we will try to demonstrate in this case scientific research, by asking the following questions:

• How the implementation of EMS in the units of production in the industrial park of the Mohammedia city contributes in the development process and continuous improvement?

• How the units of production in the industrial park of the Mohammedia city were able to improve its environmental performance?

Application Scope

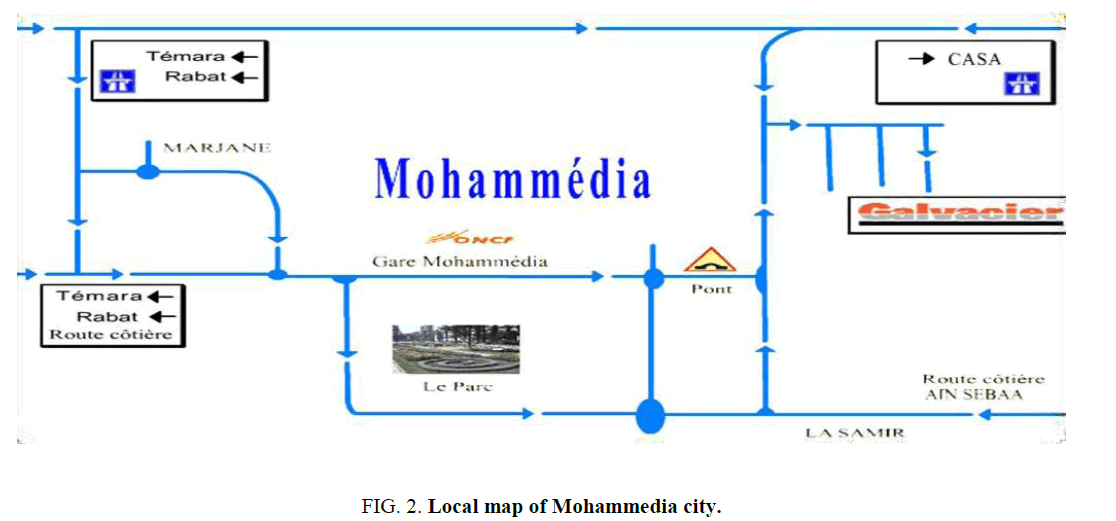

Mohammedia city lies along the Atlantic Ocean 15 miles (24 km) northeast of Casablanca. It is located between the administrative capital and the economic capital of Morocco (Figure 2) [9]. Mohammédia has a Mediterranean climate. The moderating effect of the Atlantic Ocean influences strongly on the city climate and makes its winter soft and warm and its summer hot and cool. Mohammédia enjoys plenty of sunshine throughout the year with measurable precipitation annually.

Mohammedia city is the border of Chaouia Ouardigha region in which agriculture is an important activity. Crops grown in the region are highly diversified (cereals, pulses, vegetables, industrial and fodder).

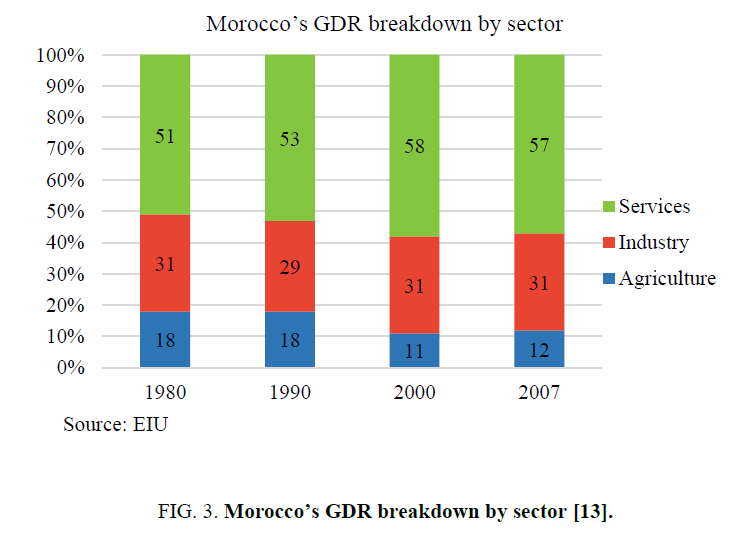

For the economic and industrial dimension, Mohammedia city among the principal cities of the region Casablanca-Settat. It is an active and a dynamic industrial city. Casablanca-Settat had a gross domestic product of 290 billion Moroccan dirham’s in 2013, accounting for 32% of Morocco's GDP and ranking first among Moroccan regions [10]. Its economy is primarily based on services and industry (Figure 3) [11]. In addition, the Doukkala area in the west is noted for its agricultural output [12].

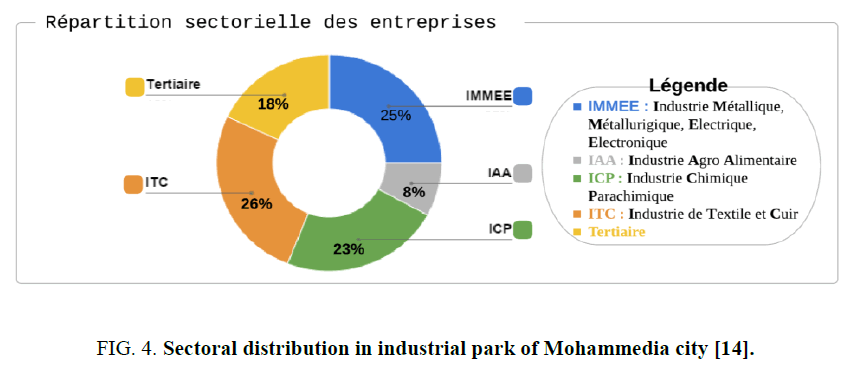

The industrial area of Mohammedia covers an area of 117 hectares. The first tranche of 57 hectares is divided into 282 lots, 217 2nd category and 3rd category 65. The first batches are intended for all promoters of non-polluting industries, while the second category are interested in small industrial units, craft and trade (Figure 4). The grounds of this tranche are particularly suited to young promoter’s requirements. R+3, they lend themselves to the construction of units on the ground floor, offices and dwellings above. Prices vary depending on the area of 900 DH for small (293 m2 to 360 m2) to 350 DH for the largest (from 3147 m2 to 3503 m2).

Our study on the units of production in the industrial zone of the city of Mohammedia. The choice of this sector was imposed by the vocation of the city considered a dynamic industrial area of Morocco kingdom.

Methodological Approach

The industrial zone of Mohammedia city is an area whose size, characteristics and location are conducive to the development of innovation and continuous improvement and proactive approach to environmental impact.

Indeed, when it comes to talking about environmental impact, large groups are generally stigmatized first. They therefore undergo greater pressure from different stakeholders (legal authorities, customers, investors, general public) and have to be very innovative in environmental strategies to respond adequately to these pressures. Therefore, it is relatively easy to find a person whose job requires constant attention on issues such as the environmental impacts generated by the company in charge of quality services/security/environment is the interlocutor par excellence.

For data collection, we conducted tours of the TGE technology and industrial area in question and conducted a series of interviews with officials and departments concerned, based on an interview guide adapted to the nature of the information sought. We also used the annual activity reports exercised in companies contacted and their quality manuals. Guide issues can advance gradually to finally achieve concrete and specific issues related to the functioning of companies contacted and their degree of involvement in the spirit of continuous development and améloiration.

Environmental Practices of Industrial Park of Mohammedia City

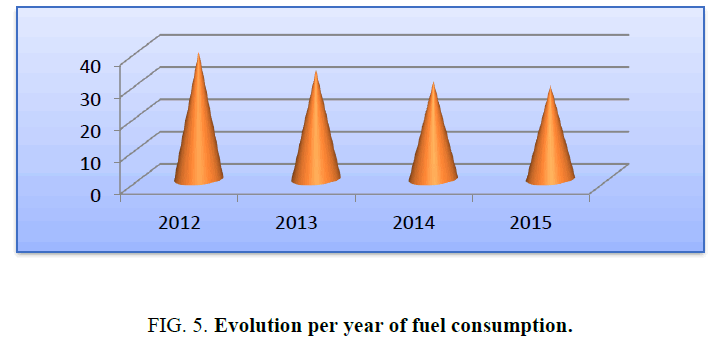

The question of the environment is a central concern of industrial park of Mohammedia city, it has introduced modern development mechanisms ensuring compliance with environmental standards, and environmental policy of the industrial park led to ISO 14001 certification. In our scientific research, we studied the four main environmental aspects according to the process of Productions along two axes ( Figure 5):

• Reducing the consumption of raw material: for example: water and energy (fuel).

• The waste treatment improvement: liquid, solid and atmospheric.

Reducing fuel consumption

• Acquisition of Efficient Boiler

• Acquisition devices Technology Achievers: Broadcaster, dryer, Cooked continues.

• Adapting a new thermal scheme

In terms of water

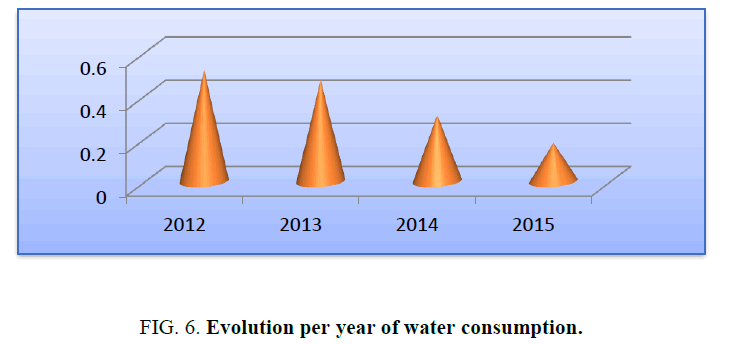

In industrial zone of Mohammedia city of, industrial water consumption decreased from 0.43 m3/tone in 2011 to 0.18 m3/tone in 2013, well below the regulatory threshold of 0.16 m3/tone (Figure. 6).

Figure 6: Evolution per year of water consumption.

Water consumption reduction

• Changing the decalcification process with zero discharge of brackish water.

• Changes in water circuit and optimization of recycling.

• Increased processing daily factory.

• Use devices more efficient technology.

By improvement discharges of treatment

The overall amount of the expansion project is estimated at 855 million dirhams of which 40 million dirhams dedicated to the environmental upgrade.

Liquid discharges

The liquid discharge is affected by the discharge pressure [15], and the water (for example candy) is used to:

• Washing beet samples at the reception center

• The washing beet.

• Extraction of (e.g. sugar) to the step of diffusion

• The steam production boiler

• Cooling machines

• Washing of filters

• The various cleanups

These waters are routed to the lagoons are buried several months to significantly reduce the parameters of organic pollution such as MES, BOD, COD, etc. The water is then discharged to the straining and the sludge is collected at the first basin decanting; after evaporation of the water and reused in the field.

Decrease in liquid releases

• Discharges from factories in the industrial zone of Mohammedia city are fully stocked in ponds.

• Use of a novel process for the regeneration of the decalcification and resin that consumes zero m3 water.

• Optimization of the circuit water and automation of beet processing.

• Pressing scum and reuse of water in the press process (filter press PKF).

• Implementation of clean technology (RNS: ion exchange columns and filters PKF sludge).

• Increase in area of natural lagoons by the construction of a new basin additional 190,000 m3 capacity for wastewater collection. The overall retention capacity is around 496,000 m3 to purify the liquid discharges advantage.

The lagoon system has undergone continuous improvement in order to optimize the environmental friendliness:

• A geological profile study of liquid waste storage ponds demonstrated that these basins are waterproof.

• These lagoons follow an annual plan of insect and rodent control.

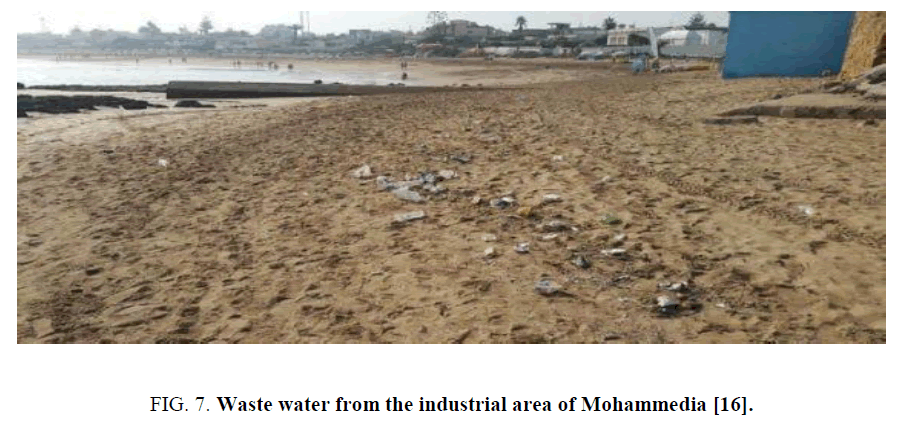

• Following numerous complaints from local residents about bad odors from the lagoon system (this is generated by the water stagnation and lack of oxygen), the site has introduced aerators very low energy consumption for brewing water and thus removing odors. It is to highlight that makes two campaigns as candy installed at the lagoons of oloides (agitators - Brewers) whose goal is to oxygenate the stored water to degrade the organic matter present in these waters. It is low power consumption stirrer (0.2 kW/stirrer) with a special form of mobile which allows an air incorporation yield better than conventional agitators and reduce olfactory nuisances ( Figure 7).

Figure 7: Waste water from the industrial area of Mohammedia [16].

Air emissions

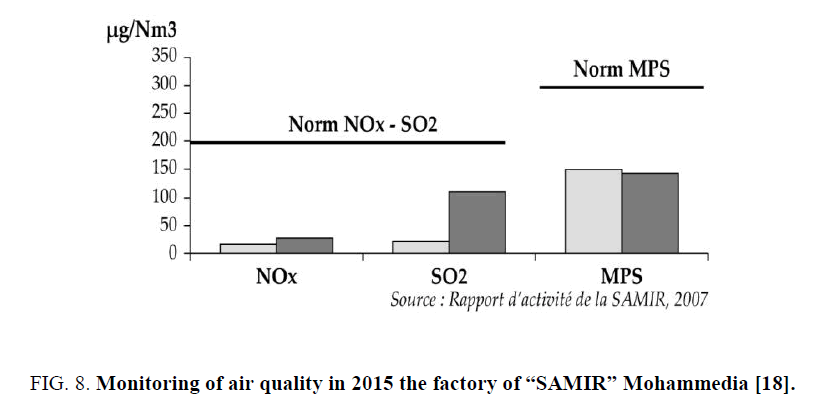

Air emission control is enforced when the ambient air quality or the source air emission rate does not meet certain standards, there are three basic approaches to air emission control: pre, in-, and post- combustion air emission control [17].

Although the factories of production have not set a quantified with regard to this aspect purpose, units of production ensure legal compliance threshold is not exceeded. Factories production conducts an annual study on the characterization of atmospheric emissions from these plants by LPEE "Public Testing Laboratory and Studies". The recent results were in line with regulatory provisions (Figure 8).

Air emissions reduction

• The improved boiler efficiency and reducing fuel consumption to less than 32 kg/ton beet which contributed to the reduction of air emissions.

• Minimize starts which emit gaseous discharges avoiding trips

• Elimination of blackish dust and fumes at the pulp dryers (baffling, bucket elevator transport).

Solid releases

A waste control is performed at each entity: waste is sorted, indexed and classified according to their degree of danger, the waste is sorted by their producers and stored (staging) on site at defined locations while ensuring compliance with environmental and safety regulations.

Garbage by type of waste are provided for this purpose in different areas of the site and their content is transferred, whenever necessary, in larger volume containers installed in the discharge. These containers are removed by external service provider to the landfill. The waste generated by the use of chemicals is rare considering the fact that the order in chemical is made according to specific needs related to the campaign.

Ordinary industrial waste (DIB): All waste can be discharged to the landfill (Table 2).

| Type | Fashion collection | Final destination |

|---|---|---|

| Garbage | Stored in collection vehicles | municipal landfill |

| demolition waste free of toxic elements | Deposited in the areas provided for this purpose | Reused in civil works |

| Sludge and land | Stored in the basins of the wash water | Evacuated to disused quarries |

| Ecumes | Evacuated to disused quarries |

Table 1: Treatment of industrial waste.

| Type | Fashion collection | Final destination |

|---|---|---|

| Cloths used during activities of maintenance |

Locked in metal drums closed deposited in the landfill controlled |

external provider issuing a certificate |

| waste oils | Recovered in drums deposited in the landfill | external provider issuing a certificate |

| contaminated absorbent | external provider issuing a certificate | |

| Chemical products: - Operations - Laboratory |

Obsolete they stored at the laboratory |

specialized agency |

Table 2: Treatment of industrial waste.

Special industrial waste: All types of waste that, by their nature hazardous, toxic, reactive, explosive, flammable, biological or bacterial, constitutes a danger to health, safety and / or the environment.

Re-recyclable waste: All waste that can be sold, regarding maintenance waste and waste packaging, they are valued and sold as is for the buyers.

Reduction of solid waste:

• The dried foams are currently evacuated to disused quarries with usability in liming to acid soils.

• Contact for ongoing use of foams in cement and brick.

• Use screenings (waste lime kiln) for redevelopment of the tracks.

ISO 14001 comprises, in Chapter 4 "EMS Requirements" requirements in five paragraphs, taking account the data on the industrial zone of Mohammedia city WE can establish the requirements of the standard as follows:

Discussion

ISO 14001 includes requirements distributed in the form of paragraphs, taking account on the data collected and the results we can establish the requirements of the standard as follows:

Requirement 1

5.1 Environmental policy: unites production of the industrial zone of the city of Mohammedia endeavor to implement a policy management and continuous improvement of industrial facilities with the aim of preserving the 'environment.

• They implement control systems required by permanent and effective measures.

• In their Business Conduct charters, unites The production of the industrial zone of the city of Mohammedia undertake to respect all the laws regarding environmental protection and to “maintain biodiversity, ecosystems, the depletion of natural resources, waste management and toxic substances”.

Requirement 2

A.6 Planning (plan): Developing methods to carry out the action program developed taking into account, in particular, normal and abnormal operating situations, from the perspective of stakeholders, technical capacity, human and financial of the company.

Requirement 3

4.4 Implementation and operation (do): Reduced consumption of raw material

• “Consumption of energy and water consumption” and reducing releases “liquid, solid and atmospheric”.

Requirement 4

A.8.1 Control (check): Existence of a mapping of environmental impacts is reviewed every two years and every major event. It lists the number of impacts, their criticality and the number of significant impacts and compliance unites the production of the industrial zone of the city of Mohammedia with environmental regulations. It is accompanied by an action plan for the implementation of measures to reduce these impacts.

Requirement 5

A.9.3 Management Review (Act): Awareness raising and training for the employees on the environmental aspects are regularly deployed. Human, organizational and financial resources are allocated to monitor environmental policy that the competence of personnel on the basis of predetermined skills matrix system defines the standard by which the company must comply [19].

• Internal audits are conducted by the QSE manager of the company, in addition, external certification audits are carried out regularly.

• Thus the evolution of environmental aspects tends towards better optimization of resources used: reduction of water consumption that announces a gap of -0, 06, and fuel consumption with a difference of -0.84 compared to the target value. This means that the target achievement rate of almost 100% for these environmental aspects. It should be noted that in 2013 and 2014, the units of production had suffered from harsh weather and a general reluctance of farmers to produce sugar beet, which resulted in a low output compared to that of previous years.

According to the study of SME requirements and tables’ environmental edge, one can conclude that the unites production of the industrial zone of the city of Mohammedia conducted several actions to preserve the environment through streamlining energy consumption and control of gaseous and liquid discharges through an investment of 100 million DH devoted to environmental upgrading:

• The optimization of water system and automation of the beet processing process after which the water consumption has been significantly reduced to less than 0.16 m3/tone beet.

• The installation of clean technology (ion exchange columns and filter press sludge) that neutralizes releases from decalcification and liquid foams.

• The increase of the area of natural lagoons in the development of a new additional pool of 190,000 m3 for wastewater collection whose overall retention capacity is around 496,000 m3 to further purify liquid waste.

• The improved boiler efficiency and reducing fuel consumption to less than 32 kg/ton beet which contributed to the reduction of air emissions.

• The installation of an innovative technology for the 2013 campaign for the elimination of odor emissions.

• Planting about 2,000 trees around the factory.

• Strengthening of consumables rationalization program.

• Support of the network of farmers to convert to drip, contributing to a 30% reduction in their water consumption per year.

• Study for the rational use of pesticides and nitrogen fertilizers.

Conclusion

The ISO 14001 standard prescribes how a company can develop an environmental policy, identify environmental aspects and impacts of their activities, products and services, define the significance of these impacts; rank them, identify legal and other requirements governing the organization's operation, establish objectives and targets, implement programs to meet those standards, establish an auditing system and procedures for management review, and implement corrective action, if needed, based on audit findings [20].

The impact of the implementation of EMS ISO 14001: 2015 in the units of production of the industrial zone of Mohammedia city of on the development and continuous improvement is positive, since in addition to environmental by compliance with laws and standards by the company; it provides a remarkable economic gain which affects socially. The industrial area of Mohammedia city contributes substantially to improving incomes of producers whose number is 220,000 and the socio-economic development of the region by generating income and employment (7.2 million workdays, 240,000 permanent jobs).

Finally, we can confirm that the integration of the development and the continuous improvement approach in environmental management system project can ensure the improvement of environmental performance, defined as measurable outcomes environmental management system in relation to the control by the organization's environmental aspects on the basis of its environmental policy, objectives and environmental targets [21]. In fact, the environmental impact is, remember, the effect and its cause is the environmental aspects of the business activity [22].

References

- Louis T, Ryan DR, Terry EB. Environmental Management: Problems and Solutions. Boca Raton: CRC Press; 1998.

- http://www.iso.org/iso/introduction_to_iso_14001.pdf

- Boubaker L. Contribution to the integration of environmental policy in the activities of Algerian companies in order to improve their environmental performance. Villeurbanne: HAL; 2012.

- http://www.epe-asso.org/guide-dauto-diagnostic-environnemental-outil-de-gestion-pour-les-entreprises-2002/

- Marquet PS. Control of Environmental Management. Belgium: UCL Louvain University; 2003.

- Gendron C. Environmental management system. An ISO 14001. Montreal: The University Press of Montreal; 2004.

- Robert F. The Handbook of Global Climate and Environment Policy. New Jersey: John Wiley & Sons; 2013.

- Raj R. Corporate Planning and Strategic Human Resources Management. 1st ed. Pune: NiraliPrakashan; 2007.

- Local office of real estate conservatory in Mohammedia.

- Masmoudi K. Regional accounts: Two poles account for half of GDP. The Economist. 2015 Sep 08.

- Regions of Morocco: The Great Casablanca. Situation of Moroccan Centre; 2015.

- Casablanca- Settat, a "mega- region" with great potential; 2015.

- http://www.cia.gov/cia

- Regional center for investment in Mohammedia city.

- Muhammad Rashid Usman. Comprehensive Dictionary of Chemical Engineering. Raleigh: Lulu.com; 2015.

- Picture from Monica Beach of Mohammedia City.

- Zhongchao T. Air Pollution and Greenhouse Gases: From Basic Concepts to Engineering Applications for Air Emission Control. Berlin: Springer; 2014.

- Company's activity report of ?LA SAMIR?; 2007.

- Woodard F. Industrial Waste Treatment Handbook. 2nd ed. Oxford: Butterworth-Heinemann; 2006.

- Mzoughi N. Analyze economic environmental regulation of the voluntaries approaches economics and finance. Dijon: Universities of Burgundy; 2006.

- André S. Evaluation synthesis ex post environmental performance of industrial sites, Sites where the entity refining company total. Paris: Lamsade; 2006. p. 241.

- Sheldon C, Yoxon M. Environmental Management Systems: A Step-by-Step Guide to Implementation and Maintenance Hardcover. 3rd ed. London: Earthscan; 2006. p. 296.