Original Article

, Volume: 12( 11)Study of Surfactants Effect on Pulp Properties

- *Corresponding Author:

- Ghaffarzadeh Mollabashi O, Department of range and watershed management, Faculty of Agricultural and Natural Resources, University of Mohaghegh Ardabili, Ardabil, Iran, Tel: +989145698654; E-mail: omid_ghafarzade@yahoo.com

Received Date: October 25, 2016; Accepted Date: November 03, 2016; Published Date: November 07, 2016

Citation: Ghaffarzadeh Mollabashi O. Study of Surfactants Effect on Pulp Properties. Environ Sci Ind J. 2016;12(11):119.

Abstract

The effects of various surfactants have been considered on soda pulping of three lignocellulosic materials. So, wheat straw, populous and forest hardwood mixture has been cooked with and without surfactant based as soda method. In order to evaluate the surfactants effects, pulp properties including the screen yield and kappa value have been measured. The results showed that in case of wheat straw and populus pulping, it has not seen any remarkable effect on kappa number, but the pulp yield improved and the screen rejects has been approximately vanished. In case of forest hardwood mixture, a different trend has been observed; so, that in successive replicates of control pulping, a variety of amounts has been observed for the pulp yield and kappa value. As a matter of fact, it is not logical to expect a constant amount for yield, kappa number. In fact, different ratio of species with different amounts of lignin and holocellulose would cause not to obtain an approximate constant amount of the yield and kappa number in successive replicates. However, the positive effects of surfactant application including yield improvement and kappa reduction have been observed in this case, too.

Keywords

Wheat straw; Populus, Hardwood mixture; Yield; Surfactant; Kappa number

Introduction

The main motivation of surface active material usage in pulping is reduction of the surface tension between the liquor and chips caused by this group of material. In case of softwoods, the blocked vessels with extractives could be opened via saponification and emulsification caused by the surface-active material [1]. Usage of the surface-active material which named ‘surfactant’ in then, would result in efficient penetration and diffusion of the cooking liquor and effective wetting of the chips' surface. This gives rise to more uniform cooking with lower kappa number, lower screen rejects, lower resin content, and improved black liquor residual active alkali [2,3].

As a matter of fact, the positive effects of surfactant usage have been proved in case of some softwood. Utilization of seventeen kinds of the surfactants in pulping and bleaching of Pinus pinaster has been considered via Baptista et al. [4]. They observed that the value of kappa number, chemical consumption, and screen rejects were decreased, while brightness was increased. As well as, they stated that nonionic surfactants gave the best results among the cationic, anionic, nonionic and amphoteric kinds. Dugiralla [2] observed that the addition of 0.1% surfactant to kraft pulping liquor (on oven dry wood) resulted in a more uniform cook with a significant decrease in kappa number; moreover, it led to an increase of about 0.5% to 1% in the yield value at a constant kappa number. Since that the surfactants act based as surface tension reduction between the surfaces of two reactants, it could be tested surfactant uses in pulping of the sources with less amount of extractive and fewer vessel bottleneck. In fact, it is expected surfactants would probably be effective in case of other raw materials i.e. hardwoods and nonwood. In this field, Guo et al. [5] indicated that the use of PEG in hardwood kraft pulping improved the delignification rate, selectivity, and yield value. In addition, Mishra et al. [6] used some non-ionic surfactants in the pulping of a bamboo and hardwood mixture. This approach resulted in reduction of extractives, kappa number, COD, TSS, and screen reject. In addition, the brightness of the unbleached pulps improved. Santiago et al. [7] showed that the application of an alcoholic surface-active material in pulping of Eucalyptus globules improved the pulp viscosity in a constant kappa number without any effect in pulp yield in comparison with conventional pulp. Therefore, it is aimed to consider the surfactant utilization as soda pulping additive of three of most abundant raw material in Iran including wheat straw, planted populus (non- forest) and forest hardwood mixture.

Experimental

Raw material

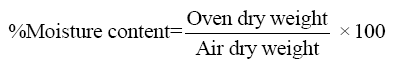

Wheat straw, populus and a mixture of forest hardwood have been used as raw materials in this study. Wheat straw samples were prepared from wheat farms of Golestan province in Iran and then transported to the laboratory to convert to the suitable dimension useable in pulping process. In this case, the clusters were removed using by farming clipper and the rest of the stalk was cut to fragments about 2 cm to 2.5 cm. In case of populus, the prepared disc samples were chipped to the suitable dimension (3 cm in length and width and 4 mm in thickness) using by laboratory chipper. The samples were prepared from shast kalateh forest, Gorgan, Iran. Finally, the forest mixture which included forest species i.e. beech, populus, birch, hornbeam, alder, parrotia with a non-determined ratio, have been prepared from the Choka wood factory's yard in northern Iran. The prepared samples were in the chips forms and therefore in this case only, it does not need any chipping operation. All three kinds of samples including wheat straw and populus and forest hardwood mixture, were transported to the pulp and paper laboratory. The samples were air-dried. At first, the samples separately kipped in polyethylene bags in order to avoid the air exchange. Then, the moisture contents were measured for three kinds of samples. To this purpose, in case of all three samples, two samples weighting 2 g were selected from the polyethylene bags (air-dried weight) and kept for 24 h in the oven in temperature of 103°C (based as the related After passing the time, the samples were weighted again (oven-dried weight). Finally, the moisture content was calculated for the three samples according formula 1 below:

Methods

The pulping operation was carried out in a set of cylindrical rotating digesters based as soda method with and without some surfactants. In fact, some parallel cooks have been designed for each of the samples; conventional soda and modified with some of surfactants usage which named in then "soda-surfactant". In other words, in the soda-surfactant cooks, a variety of the surfactants have been added to cooking liquor. The process conditions for the three samples have been separately described in next.

Wheat straw pulping

Firstly, conventional soda cooking (code W1 in Table 1) was carried out with the following conditions. Straw weight, 100 g (based on oven dry); liquor to straw ratio, 7:1; maximum temperature, 160°C; active alkali (based as NaOH) of 20% on oven dry of the straw and times at maximum temperature of 90 min. These conditions were chosen after some pretests in an effort to achieve a kappa number less than 20 (bleachable pulp). Afterwards, surfactants were used at 0.5% and 1% dosages based on oven-dry straw (codes W2 to W5 in Table 1).

| Raw material | Surfactant type | Surfactant dosage | Code |

|---|---|---|---|

| Wheat straw | - | 0% | W1 |

| Lauryl alcohol ethoxylate 7 mole | 0.5% | W2 | |

| 1% | W3 | ||

| Poly ethylene glycol 1500 | 0.5% | W4 | |

| 1% | W5 |

Table 1: All treatments of soda and soda-surfactant of wheat straw.

Populus pulping

In this case, the control treatment (code P1 in Table 2) was carried using 100 g of the populus chips based as oven dry. Liquor to wood ratio was selected 5:1, active alkali (based as NaOH) of 25% on oven dry of straw and times at maximum temperature of 120 min. This condition has been selected after some pretests in order to obtain less amount of the screen rejects (<3%) and achievement of the kappa less than 20. In next step, three kinds of surfactants were solved into cooking liquor in three different dosages of 0.5%, 1% and 5% (codes P2 till P10 in Table 2).

| Raw material | Surfactant type | Surfactant dosage | Code |

|---|---|---|---|

| Populus | - | 0% | P1 |

| Lauryl alcohol ethoxylate 7 mole | 0.5% | P2 | |

| 1% | P3 | ||

| 5% | P4 | ||

| Poly ethylene glycol 1500 | 0.5% | P5 | |

| 1% | P6 | ||

| 5% | P7 | ||

| Kenol | 0.5% | P8 | |

| 1% | P9 | ||

| 5% | P10 |

Table 2: All treatments of soda and soda-surfactant of populus.

Hardwoods mixture pulping

Alike to the two above mentioned material, in case of hardwoods mixture, firstly the soda pulping has been done without using any kind surfactant. To this purpose, 100 g of the hardwoods mixture were pulped using by 25% of NaOH for 120 min. The L/W was considered 5:1 (code M1 in Table 3). A variety of surfactants with two dosages of 1% and 4% were used (codes M2 till M9 in Table 3).

| Raw material | Surfactant type | Surfactant dosage | Code |

|---|---|---|---|

| Hardwood mixture | - | 0% | M1 |

| Dodecyl sulfate sodium ammonium | 1% | M2 | |

| 4% | M3 | ||

| Poly ethylene glycol 6000 | 1% | M4 | |

| 4% | M5 | ||

| Poly propylene glycol | 1% | M6 | |

| 4% | M7 | ||

| Poly ethylene glycol 400 | 1% | M8 | |

| 4% | M9 |

Table 3: All treatments of soda and soda-surfactant of the forest hardwood mixture.

First and foremost, accept yield and screen rejects were separated. To this purpose, when cooking was ended, each pulp samples was separately washed by using tap water (non-distilled) on a 20-mesh screen and collected on a 200-mesh screen. The retained parts on the 20 and 200 mesh screens realized the reject and accept value, respectively. Then, based as accept pulp, the kappa number was measured for the all treatments (Table 1-3) according to TAPPI Method T 236 om-85. The effects of surfactants usage on pulp properties were analyzed by using one-way Anova, and the means were compared by using Duncan’s multiple comparison tests at 95% confidence level.

Results and Discussion

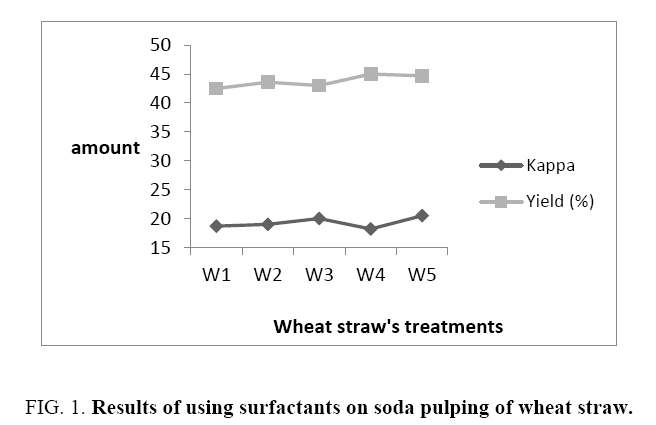

Wheat straw treatments

The results of surfactants addition to soda cooking liquor are shown in Figure 1. Figure 1 indicates that both surfactants caused to increase the accepted yield among the treatments W2 to W5. As seen, in contrary, the kappa number was decreased. The increase in accepted yield was much more significant in the case of PEG 1500 in comparison to lauryl alcohol at comparable kappa number. The lowest accepted yield is related to W1 (control treatment) and the highest increase has been observed in W4 with 0.5% usage of PEG 1500. In could be concluded that treatment W4 with 0.5% usage of PEG 1500 is the optimum condition among the four-modified pulping. The yield increase is resulted from the surfactant effect in decreasing of surface tension between the liquor and straw chips. In fact, surface active agents could improve penetration rate of the pulping liquor and therefore cause to more efficient usage of the liquor. Better penetration of the cooking liquor into the chips can result in faster defiberation of chips, reduction in rejects, and perhaps improvements in pulp yield [8-10].

The difference effects of the three used surfactants on pulp properties are maybe resulted from difference in HLB values of the surfactants. In fact, the different hydrophobic-hydrophilic balance between two surfactants affects the surfactant efficiency in pulping reaction [11].

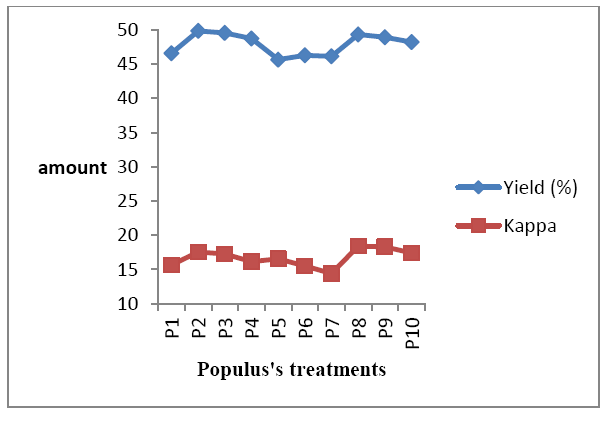

Populus treatments

Pulp properties including acceptable yield and kappa number compared to control treatment, were illustrated in Figure 2. As seen, when using lauryl alcohol and kenol, the yield value has been increased and the highest increase has been observed in case of the treatments P2 and P8 related to 0.5% of lauryl alcohol and 0.5% of Kenol additions, respectively. Moreover, it has been found that there was no effect on increasing both surfactant dosages from 0.5% to 1% and from 1% to 5% on the yield amount. Next, the effect of the lauryl alcohol and Kenol addition on kappa number was considered. As illustrated in Figure 2, both of the additives caused to increase the kappa number of the pulps. The treatment p1 (control sample) showed significantly less kappa value in comparison to the treatment which have been modified via charge of lauryl alcohol (treatments p2, p3 and p4) and Kenol (treatments p8, p9 and p10). In fact, usage of lauryl alcohol and Kenol had a positive effect on pulp properties. In opposite, addition of PEG caused to reverse outcome; so, that the yield and kappa amounts has been decreased with PEG 1500 usage. Figure 2 shows that the treatments p1 (control sample) obtained higher yield and less amount of the kappa number. In fact, usage of PEG had a negative effect on pulp properties.

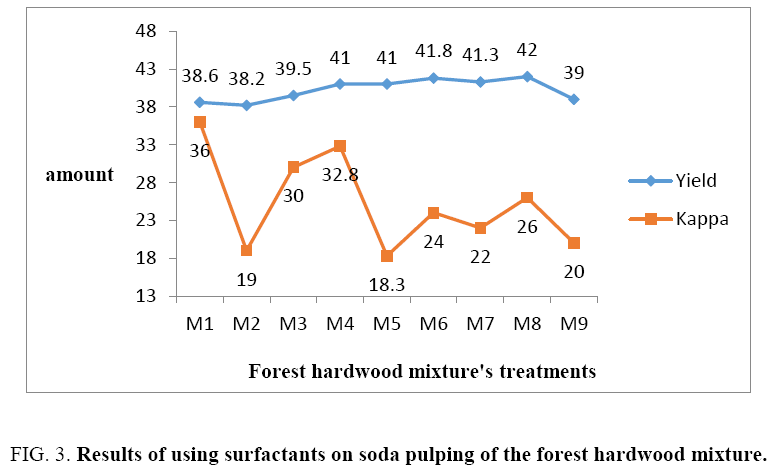

Forest hardwood mixture treatments

In this case, at first, the soda pulping of forest hardwood mixture has been carried out. As illustrated in Table 4, a variety of the kappa and yield amounts have been observed in the successive replicates.

| Replicate 1 | Replicate 2 | Replicate 3 | Replicate 4 | Replicate 5 | |

|---|---|---|---|---|---|

| Yield | 46.4 | 39.1 | 38.43 | 35.7 | 33.4 |

Table 4: Yield amount for soda pulping of forest hardwood mixture (treatment M1).

As a matter of fact, in the treatments with different ratios of the species mixture, a different amount would be obtained for the kappa number and yield. This phenomenon is related to stock of the Choka’s yard. In other words, various ratios of the species mixture are used in the successive cooking operations. Next, the modified treatments with surfactants addition have been carried out (treatments M2 to M10). As expected, alike to the control treatment (M1), a variety of yield amount has been observed in the successive replicates of each modified treatment. To resolve this factor, each process has been repeated more than 5 times and then the results have been considered based as the mean values of the replicates. Finally, the mean values for the kappa and the yield amounts have been summarized in Figure 3. It has been showed that, the addition of all four surfactants in each two dosages (1% and 4%) has caused to improve the yield amount. Among the all modified treatments, highest increase has been obtained in yield amount in the treatment M8 with 3.4% relative difference. In opposite, the treatments M2 showed about 0.4% decrease in yield amount compared to control treatment (M1). Totally, it could be concluded that usage of each four surfactants had a positive effect in the yield amount of forest hardwood mixture pulping. Moreover, it has not been observed a remarkable difference with an increase in the dosage of the surfactants from 1% and 4%. In other words, 1% usage of surfactant is preferred that is important from economic point of view, too. In fact, it would be possible to obtain a high rate of increase in yield amount with less usage of surfactant. The increase in pulp yield may be due to higher selectivity of delignification (lower dissolution of carbohydrates at certain amount of lignin dissolution), which was affected by surfactant that can act as a co-solvent [3,5,12,13]. Afterwards, the kappa variation has been considered among the soda and soda-surfactant samples (treatments M1 to M9). As seen in Figure 3, the kappa numbers of the modified pulp samples are in a lower range. In fact, surfactant addition has a positive effect in lignin dissolution in pulping process. This phenomenon is resulted from the decreasing effect of surfactants in the surface tension between the liquor and chips which resulting in wetting of the chips’ surfaces. This gives rise to more uniform cooking with lower kappa number and lower screen rejects [2,4,6]. The decreasing of the screen reject values verifies these results. The value of screen reject was about 5% in control treatments whereas in modified treatments (M2 to M9), this parameter has been decreased to less than 0.5%. The increase in yield may be expected as a result of a decrease in screen rejects [7].

Conclusion

In case of wheat straw pulping, addition of the surfactants lauryl and PEG 1500 significantly improved the yield value at the approximate same kappa number. In case of populus pulping, addition of the surfactants lauryl and Kenol improved the yield but the kappa value has been slightly increased; on contrary, addition of PEG declined both the yield and kappa value. The yield and kappa varied in the various replicates of the control treatment for forest hardwood mixture pulping; but, each four surfactants caused to enhance the yield and reduce the kappa value. These results were significantly remarkable.

References

- Chen GC. Application of surfactant as a Kraft pulping additive. Tappi J. 1994;77(2):125-8.

- Duggiralla PY. Surfactant based digester additive technology for kraft soft wood and hard wood pulping.Appita J. 2000;53(1):41-8.

- Duggiralla PY. Evaluation of surfactant as digester additives for Kraft soft wood pulping. Tappi J. 1999;88(11):121-7.

- Baptista C, Belgacem N, Duarte AP. The effect of surfactants on kraft pulping of Pinus pinaster.Appita J. 2004;57(1):35-9.

- Guo Z, April GC, Li M, et al. EG-based aqueous biphasic systems as improvement for kraft hardwood pulping process. Chem Eng Comm.2003;190(9):1155-69.

- Mishra RP, Maheshwari GD, Bhargava GG, et al. Effect of surfactant application on pulping characteristics of mill chips and reduction in pollution load. JIndian Pulp Paper TechAssoc. 2007;19(1):61-6.

- Santiago AS, Pascoal NC. Assessment of potential approaches to improve Eucalyptus globulus kraft pulping yield. J Chem Tech Biotech. 2007;82(5):424-30.

- Ahluwalia MR;Exxon Chemical Patent Inc.,Method of producing pulp. United States patent US 5032224 A. 1991.

- Ahluwalia MR, Coffy JM, Norris AD. Emerging technology in Kraft pulping with digester additives. CPPA Conference Proceedings, Canada; 1992.

- Parthasarathy VR, Grygotis RC, Wahoske KW, etal. A sulfur-freechlorine-free alternative to kraft pulping. Tappi J. 1996;79(6):189-98.

- Salager JL. Surfactants types and uses. TeachAid SurfactSciEng. 2002.

- Baptista C, Robert D, Duarte AP. Effect of pulping conditions on lignin structure from maritime pine Kraft pulps. Chem Eng J. 2006;121(3):152-8.

- Ghafarzade MO, Saraean AR, Resalati H. The effect of surfactant application on soda pulping of wheat straw. Bioresources. 2011;6(3):2711-8.