Review

, Volume: 15( 1)carbon hydrogen bond

Carbon Hydrogen bond

Imrahim*

*Corresponding author:Imrahim, Centre of Applied Chemistry and Green Chemistry, INTI International University, Putra Nilai, 71800, Negeri Sembilan, Malaysia, Tel: 606-7982000; E-mail: soonmin.ho@newinti.edu.my

Abstract

A high grade TiO2 product of 99.1% purity has successfully been prepared from the Egyptian Rosetta titania slag by its proper roasting with sodium hydroxide. The reaction product was then successively washed by water followed by controlled HCl acid leaching procedures in order not to dissolve the titanium values. The first step has aimed to dissolve silica, alumina besides possible V and Cr as well as recovering the excess NaOH while the HCl acid leaching step was so applied to selectively dissolve the iron and other impurities. The studied optimum conditions of roasting involved a slag/NaOH ratio of 5/6 at a roasting temperature of 850°C for 0.5 h. After both leaching circuits the titanium product left behind was filtered and properly washed with distilled water before drying at 110°C and calcination at 850°C.Introduction

Now-a-days, there are many techniques could be used in order to carry out a full investigation of a surface phenomenon in materials science. For example, transmission electron microscopy [1-5], X-ray diffraction [6-12], scanning electron microscopy [13-16], auger electron spectroscopy [17-19], atomic force microcopy [20-27] as reported by many researchers. Material characterization on a nano or mirco scale is often an essential part for understanding material behavior. Obviously, no one technique can ever solve each surface problem. Therefore, two or more techniques were used by material scientists in their investigation. Some important information such as chemical structure, atomic structure, chemical composition, physical topography, electronic state and description of bonding of molecules will be studied in order to understand the properties of samples.

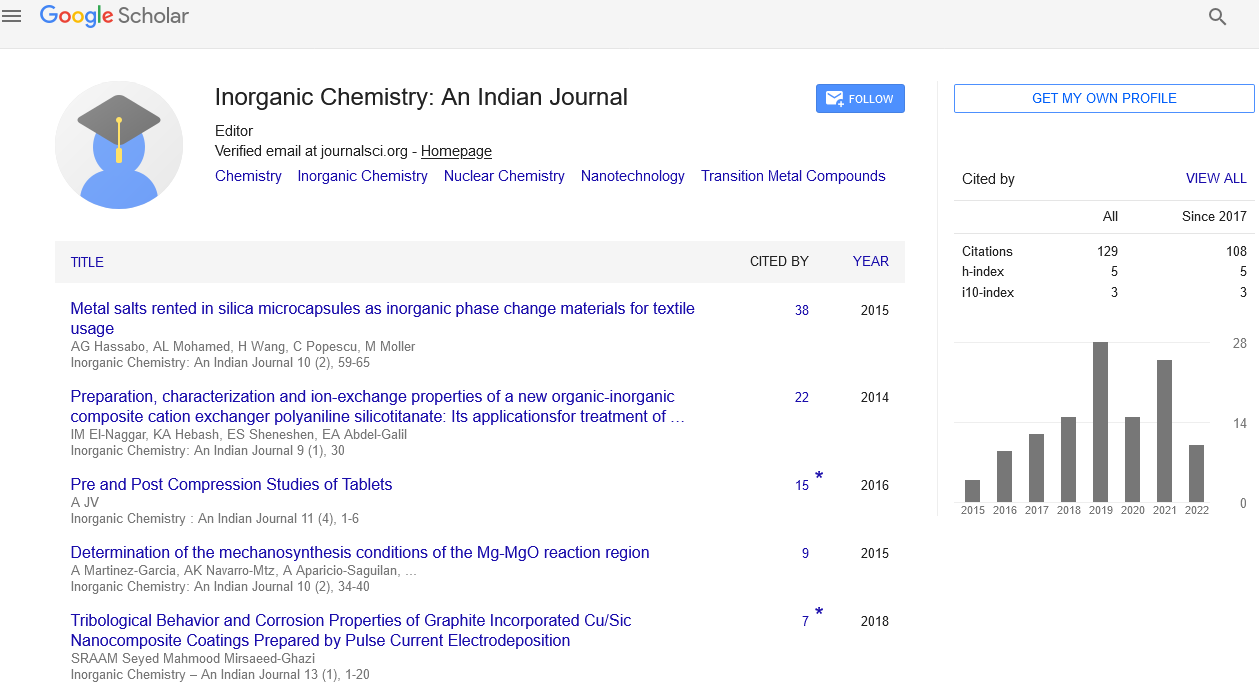

X- ray photoelectron spectroscopy (XPS) technique has been employed over the past twenty years in many areas of materials analysis include thin films, catalysis, metallurgy, semiconductor, superconductor, biomaterials, chemisorption, polymer, fibre, corrosion and oxidation. In this work, surface properties of thin films were studied by using X-ray photoelectron spectroscopy. The X-ray photoelectron spectroscopy spectra and data were discussed. The advantages of X-ray photoelectron spectroscopy technique will be described as well.

Literature Survey

X-ray photoelectron spectroscopy requires ultra-high vacuum conditions in order to measure photoelectrons emitted from thin films. Generally, X-ray photoelectron spectroscopy spectrum is produced by irradiating a material with a beam of X-rays. X-rays penetrate the specimen surface to a depth of a few micrometers. At the end of the process, the kinetic energy and number of electrons that escape from materials being analyzed.

There are several advantages by using X-ray photoelectron spectroscopy technique. The X-ray photoelectron spectroscopy sensitivity at 0.1 atomic percentage and is used to analyze the surface chemistry of samples. These samples consist of solid form or heavy oil. Generally, X-ray photoelectron spectroscopy detects all elements such as atomic number of 3 and above. Quantitative chemical information of the first 10 nm atomic layers could be done successfully using X-ray photoelectron spectroscopy. On the other hand, X-ray photoelectron spectroscopy is used to provide information on the oxidation state of each element. For instance, X-ray photoelectron spectroscopy can easily distinguish sulphates from sulphites, sulphides or sulphur. Other advantages such as ability to give chemical information, low sample damage, and simple quantitative information.

Chemical composition study by X-ray photoelectron spectroscopy as described by Deshpande et al., 2013 [28] for the CdSe films prepared using chemical bath deposition method at room temperature. The X-ray photoelectron spectroscopy spectra show the strong peaks correspond to Cd 3d, Cd 4d, O 1s and Se 3d. They obtained results are close to that of bulk CdSe. Lisco et al., 2015 [29] have developed pulsed DC magnetron sputtering to sputter cadmium sulphide thin films in highly stable process conditions. The X-ray photoelectron spectroscopy spectra indicate photoelectron core level of Cd 3d and S 2p. The binding energies obtained matched the theoretical values for CdS. They also point out that no oxygen was incorporated into the films and the films are stoichiometric. In the other case, CdS films were prepared using chemical bath deposition method in the presence of tartaric acid as complexing agent as reported by Roy et al., 2006 [30]. X-ray photoelectron spectroscopy analysis supported that the composition of CdS films annealed at 400°C. The peaks positions for Cd 3d 5/2, Cd 3d 3/2 and S 2p were obtained. Zhang et al., 2001 [31] have prepared thin films in alkaline aqueous solution. The X-ray photoelectron spectroscopy results indicate that the contents of Ag and Se are quantified by Ag 3d5/2 and Se 3d peak areas. They comment that the photoelectron emission arising from elements and oxides is not significant. SnS films were synthesized onto tin oxide glass substrates as proposed by Subramanian et al., 2001 [32]. X-ray photoelectron spectroscopy studies reveal that Sn 3d 5/2, 3d 3/2 and S 2p 3/2 peaks were attributed to SnS films. CuInS2 thin films were synthesized by Aggour et al., 2002 [33] using electrochemical deposition. Evaluation of binding energy from X-ray photoelectron spectroscopy shows Cu 2p, In 3d and S 2p peaks attribute to CuInS2 films.

Tin selenide thin films were prepared using electro deposition method as described by Lukinskas et al., 2006 [34]. Determination of elemental composition films was carried out using X-ray photoelectron spectroscopy. They conclude that interchanging deposition of tin and selenium coatings from separate solutions causes formation of SnSe, Se and SnSe2 phases. On the other hand, the chemical composition of CdS films was determined by X-ray photoelectron spectroscopy technique as reported by Urias et al., 2014 [35]. They claim that the annealing treatment has a significant effect on the composition of obtained films. For example, Cd0.6S0.4 and Cd0.55S0.45 was observed for the as-deposited films and annealed films, respectively. Khot et al., 2014 [36] have synthesized cadmium sulfoselenide thin films using self-organized arrested precipitation method. The X-ray photoelectron spectroscopy data confirmed that the composition of obtained films was a good stoichiometry

The X-ray photoelectron spectroscopy technique was employed to investigate elemental oxidation states for samples. Cu-Fe-Sn-S thin films were prepared by Meng et al., 2015 [37] using magnetron sputtering method. They reveal that the Cu+ , Fe2+, Sn4+ and S2- in the prepared films. Kamble et al., 2016 [38] have prepared ZnxCo1-xS films via chemical deposition method in an aqueous alkaline. The X-ray photoelectron spectroscopy studies established chemical states of Co2+, Zn2+ and S 2- . Reddy et al., 2015 [39] have reported the deposition of Cu2SnS3 films on soda lime glass by using co-evaporation deposition techniques. X-ray photoelectron spectroscopy analysis reveals that the oxidation states of Cu+1, Sn4+ and S-2 .

However, there are some limitations of technique such as sample compatibility with ultra-high violet and relatively poor lateral resolution of the x-ray source. In terms of elemental analysis, X-ray photoelectron spectroscopy is unable to study the helium and hydrogen due to these elements have not core orbitals. I believe that the technical aspects of X-ray photoelectron spectroscopy will be improved and the number of areas of application has also grown considerably in future. As a result, making X-ray photoelectron spectroscopy technique almost mandatory in materials sciences as reported by many researchers in their research findings [40-50].

Conclusion

Chemical composition and elemental oxidation states were investigated by using X-ray photoelectron spectroscopy. Evaluation of binding energy from X-ray photoelectron spectroscopy shows the complete synthesis for the desired binary, ternary and quaternary thin films.

Acknowledgement

INTI International University is gratefully acknowledged for the financial support of this work.

References

- Ghribi F, El-Mir L, Omri K, et al. Sputtered ZnS thin film from nanoparticles synthesized by hydrothermal route. Optik- Int. J. Light Electron Opt. 2016; 127(7):3688-92.

- Gallardo M, Ayala AM, Pal M, et al. Synthesis of pyrite FeS2 nanorods by simple hydrothermal method and its photocatalytic activity. Chem. Phys. Lett. 2016;660: 93-8.

- Mukherjee A, Ghosh P, Aboud AA, et al. Influence of copper incorporation in CdS: Structural and morphological studies. Mater. Chem. Phys. 2016; 184:101-9.

- Chen HJ, Fu SW, Wu SH, et al. Comparative study of self-constituent buffer layers (CuS, SnS, ZnS) for synthesis Cu2ZnSnS4 thin films. Mater. Lett. 2016; 169:126-30.

- Umair S, Raja AH, Amin B. Fabrication and applications of copper sulfide (CuS) nanostructures. J. Solid State Chem. 2016; 238:25-40.

- Anuar K, Ho SM, Tan WT, et al. Chemical bath deposition of ZnSe thin films: SEM and XRD characterization. Eur. J. Appl. Sci. 2011; 3:113-6.

- Vanita SR, Chandrakant DL, Vilas VK. Photoelectrochemical studies on electrodeposited indium doped CdSe thin films using aqueous bath. J. Electroanal. Chem. 2017; 788:137-43.

- Saravanan N, Anuar K, Ho SM, et al. Preparation and characterization of PbSe thin films by chemical bath deposition. Jurnal Kimia. 2010; 4:1-6.

- Ersin Y, Yasin Y. Fabrication and characterization of Sr-doped PbS thin films grown by CBD. Ceram. Int. 2017; 3(1): 407-13.

- Anuar K, Tan WT, Ho SM. Thickness dependent characteristics of chemically deposited tin sulfide films. Universal J. Chem. 2013; 1(4):170-74.

- Touati B, Gassoumi A, Dobryden I, et al. Engineering of electronic and optical properties of PbS thin films via Cu doping. Superlattices Microstruct. 2016; 97:519-28.

- Anuar K, Tan WT, Ho SM, et al. Cyclic voltammetry study of copper tin sulfide compounds. Pacific J. Sci. Technol. 2007; 8(2):252-60.

- Sathishkumar R, Devakirubai E, David A, et al. Structural and optical studies of cadmium sulfide (CdS) thin film by chemical bath deposition (CBD). Mater. Focus. 2017; 6(1):41-6.

- Alhammadi S, Moon K, Park H, et al. Effect of different cadmium salts on the properties of chemical-bath-deposited CdS thin films and Cu(InGa)Se2 solar cells. Thin Solid Films. 2017; 625:56-61.

- Amira H, Hager M. Growth of different phases and morphological features of MnS thin films by chemical bath deposition: Effect of deposition parameters and annealing. J. Solid State Chem. 2017; 247:120-30.

- Anuar K, Ho SM, Loh YY, et al. Structural and morphological characterization of chemical bath deposition of FeS thin films in the presence of sodium tartrate as a complexing agent. Silpakorn Univ. Sci. Technol. 2010; 4:36-42.

- Craig S, Dennid N, Dimosthenis S, et al. Soft X-ray absorption spectroscopy investigation of the surface chemistry and treatments of copper indium gallium diselenide (CIGS). Sol. Energy Mater. Sol. Cells. 2017;160: 390-7.

- Nicole J, Angus R, Sefik S, et al. Electrical properties from photoinduced charging on Cd-doped (100) surfaces of CuInSe2 epitaxial thin films. J. Vacuum Sci. Technol. A: Vacuum, Surf. Films. 2016;34(3). doi: http://dx.doi.org/10.1116/1.4945105.

- Jiang F, Ozaki C, Harada T, et al. Effect of indium doping on surface optoelectrical properties of Cu2ZnSnS4 photoabsorber and interfacial/photovoltaic performance of cadmium free In2S3/Cu2ZnSnS4 heterojunction thin film solar cell. Chem. Mater. 2016; 28:3283-91.

- Deshpande MP, Garg N, Bhatt SV, et al. Characterization of CdSe thin films deposited by chemical bath solutions containing triethanolamine. Mater. Sci. Semicond. Process. 2013; 16(3):915-22.

- Ho SM, Saravanan N, Anuar K, et al. Temperature dependent surface topography analysis of SnSe thin films using atomic force microscopy. Asian J. Res. Chem. 2012: 5:291-94.

- Daniel T, Henry J, Mohanraj K, et al. Fabrication of ITO/Ag3SbS3/CdX (X = S,Se) thin film heterojunctions for photo-sensing applications. Mater. Res. Express. 2016;3(11). doi: https://doi.org/10.1088/2053-1591/3/11/116401.

- Ho SM, Anuar K, Atan S, et al. X-ray diffraction and atomic force microscopy studies of chemical bath deposited FeS thin films. Stud. Univ. Babes-Bolyai Chem. 2010;55(5): 5-11.

- Mukherjee A, Ghosh M, Fu M, et al. Microstructural characterization of chemical bath deposition synthesized CdS thin films: Application as H2S sensor. Adv. Sci. Lett. 2016; 22. doi: 10.1166/asl.2016.6779.

- Ho SM, Anuar K, Nani R. Atomic force microscopy studies of zinc sulfide thin films. Int. J. Adv. Eng. Sci. Technol. 2011;7:169-72.

- Soumya RD, Ajaya KS, Lata D, et al. Structural, morphological and optical studies on chemically deposited nanocrystalline CdZnSe thin films. J. Saudi Chem. Soc. 2014;18:327-39.

- Ho SM. Atomic force microscopy investigation of the surface morphology of Ni3Pb2S2 thin films. Eur. J. Sci. Res. 2014;125:475-80.

- Deshpande MP, Garg N, Bhatt SV, et al. Spectroscopy and structural study on CdSe thin films deposited by chemical bath deposition. Adv. Mater. Lett. 2013;4(11):869-74.

- Lisco F, Kaminski PM, Abbas A, et al. The structural properties of CdS deposited by chemical bath deposition and pulsed direct current magnetron sputtering. Thin Solid Films. 2015;582:323-27.

- Roy P, Srivastava SK. A new approach towards the growth of cadmium sulphide thin film by CBD method and its characterization. Mater. Chem. Phys. 2006;95(2):235-41.

- Zhang W, Yang Z, Liu J, et al. A simple synthesis of nanocrystalline binary metal chalcogenides in alkaline aqueous solution. J. Solid State Chem. 2001;161(2):184-9.

- Subramanian B, Sanjeeviraja C, Jayachandran M. Cathodic electrodeposition and analysis of SnS films for photoelectrochemical cells. Mater. Chem. Phys. 2001;71(1):40-46.

- Aggour M, Störkel U, Murrell C, et al. Electrochemical interface modification of CuInS2 thin films. Thin Solid Films. 2002;403-404:57-61.

- Lukinskas A, Jasulaitien? V, Lukinskas P, et al. Electrochemical formation of nanometric layers of tin selenides on Ti surface. Electrochem Acta. 2006;51(27):6171-78.

- Urias D. Marquina A, Mendoza D, et al. Annealing effect on structural, morphological, and optical behaviors of CBD-CdS nanostructured films for solar cells. Opt. Mater. Express. 2014;4(11):2280-89.

- Khot KV, Mali SS, Pawar NB, et al. Development of nanocoral-like Cd(SSe) thin films using an arrested precipitation technique and their application. New J. Chem. 2014;38(12):5964-65.

- Meng X, Deng H, Sun L, et al. Sulfurization temperature dependence of the structural transition in Cu2FeSnS4 based thin films. Mater. Lett. 2015;161:427-30.

- Kamble SS, Dubal DP, Tarwal NL, et al. Studies on the ZnxCo1−xS thin films: a facile synthesis process and characteristic properties. J. Alloys Compd. 2016;656:590-97.

- Reddy TS, Amiruddin R, Kumar MS. Deposition and characterization of Cu2SnS3 thin films by co-evaporation for photovoltaic application. Sol Energy Mater Sol. Cells. 2015;143:128-4.

- Iacomi F, Salaoru I, Apetroaei N, et al. Physical characterization of CdMnS nanocrystalline thin films grown by vacuum thermal evaporation. J. Optoelectron. Adv. Mater. 2006;8(1):266-70.

- Leon HA, Heredia G, Leon AD, et al. Comparative study of PbS thin films growth by two different formulations using chemical bath deposition. Chalcogenide Lett. 2016;13:161-68.

- Thota N, Gurubhaskar M, Sunil MA, et al. Effect of metal layer stacking order on the growth of Cu2ZnSnS4 thin films. Appl. Surf. Sci. 2017;396:644-51.

- Baudet E, Cardinaud C, Girard A, et al. Structural analysis of RF sputtered Ge-Sb-Se thin films by Raman and X-ray photoelectron spectroscopies. J. Non-crystalline Solids. 2016;444:64-72.

- Taur VS, Joshi RA, Ghule AV, et al. Effect of annealing on photovoltaic characteristics of nanostructured p-Cu2S/nCdS thin film. Renew. Energy. 2012;38(1):219-23.

- Yu F, Ou S, Yao P, et al. Structural, surface morphology and optical properties of ZnS films by chemical bath deposition at various Zn/S molar ratios. J Nanomater 2014. doi: http://dx.doi.org/10.1155/2014/594952.

- Ali N, Hussain A, Ahmed R, et al. Synthesis and characterization of copper antimony tin sulphide thin films for solar cell applications. Appl. Surf. Sci. 2016;390:393-8. www.tsijournals.com | April 2020 6

- Kovalskiy A, Vlcek M, Palka K, et al. Structural origin of surface transformations in arsenic sulfide thin films upon UV-irradiation. Appl. Surf. Sci. 2017;394:604-12.

- Santoni A, Rondino F, Malerba C, et al. Electronic structure of Ar+ ion-sputtered thin-film MoS2: A XPS and IPES study. Appl. Surf. Sci. 2017;392:795-800.

- Chalapathi U, Poornaprakash B, Park SH. Chemically deposited cubic SnS thin films for solar cell applications. Sol. Energy. 2016;139:238-48.

- Shi D, Wang G, Li C, et al. Preparation and thermoelectric properties of MoTe2 thin films by magnetron cosputtering. Vacuum. 2017;138:101-4.