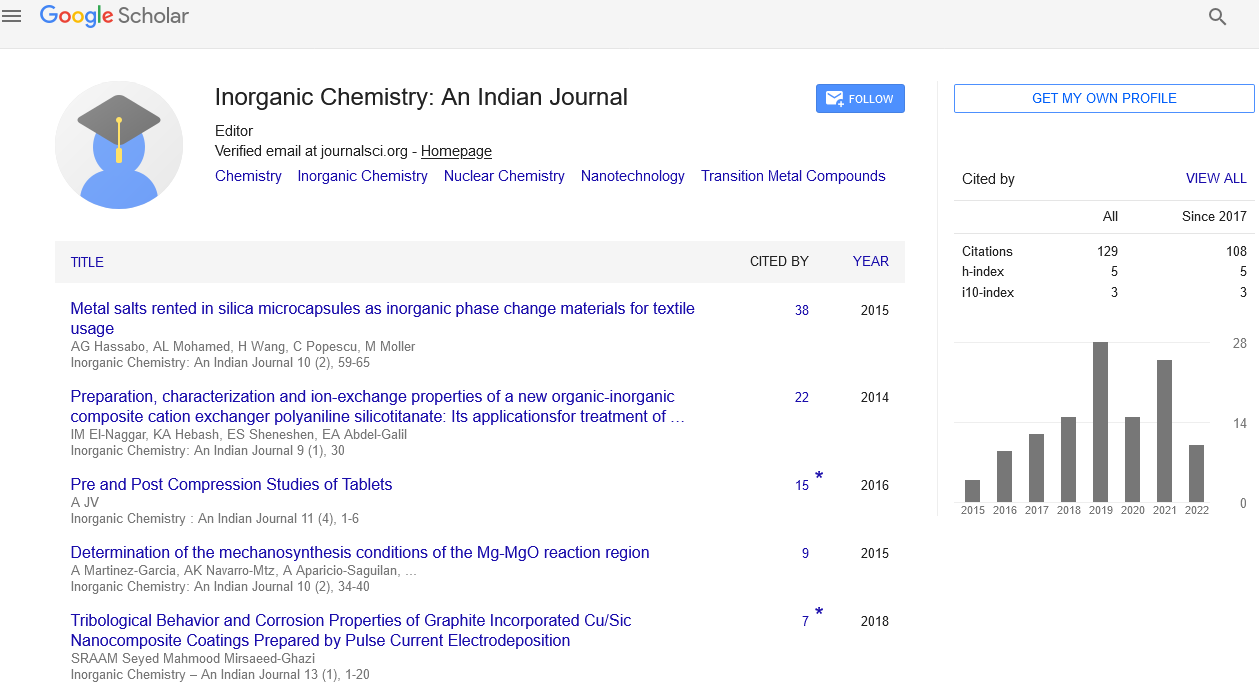

Abstract

Tribological behavior and corrosion properties of graphite incorporated Cu/SiC nanocomposite coatings prepared by pulse current electrodeposition.

Author(s): Seyed Mahmood Mirsaeed-Ghazi, Saeed Reza Allahkaram and Arman MolaeiIn this research, Cu/SiC/graphite nanocomposite coatings were fabricated by using pulse current (PC) electrodeposition method in the sulfate bath. The effects of PC parameters, like frequency, duty cycle, current density, and graphite concentration in the electrolyte bath, on the codeposition of graphite microparticles in the coating were analyzed. Also, the Cu-based composite coatings were tested by means of scanning electron microscopy (SEM) equipped with energy dispersive X-ray (EDX) spectroscopy, Vickers microhardness, and X-ray diffraction (XRD) techniques. Finally, the corrosion behavior of coatings in 3.5 wt.% NaCl solution were evaluated by using potentiodynamic polarization technique. The maximum code position of graphite was achieved at the current density of 12 A/dm2 , frequency of 15 Hz, duty cycle of 7%, and graphite content of 60 gr/l. Increasing graphite microparticles and decreasing SiC nanoparticles in the Cu-based composite coatings led to a decrease and increase in SiC content of the deposition, microhardness, friction coefficient, corrosion, and wear resistance, respectively. Furthermore, by embedding desirable SiC and graphite particles, Cu-based coating on the Cu substrate obtained both great wear and corrosion resistance.