Original Article

, Volume: 15( 4)Preparation of Sustainable Asphalt Pavements Using Polyethylene Terephthalate Waste as a Modifier

- *Correspondence:

- Al-Mulla EAJ, College of Health and Medical Techniques, Al-Furat Al-Awsat Technical University, Al-Kufa, Iraq, Tel: 009647831488924; E-mail: almullaemad@atu.edu.iq

Received: August 18, 2017; Accepted: August 22, 2017; Published: August 28, 2017

Citation: Al-Mulla EAJ, Makky SM. Preparation of Sustainable Asphalt Pavements Using Polyethylene Terephthalate Waste as a Modifier. Int J Chem Sci. 2017;15(4):178

Abstract

Industrial development and contemporary life style led to spread a large amount of non-biodegradable plastic waste. This paper aims to study the effects of recycling polyethylene terephthalate (PET) plastic waste which is a type of disposable plastic packaging waste as an asphalt modifier, to create a sustainable asphalt pavement and improving the rheological properties and temperature susceptibility. PET waste was blended with asphalt cement in three percentages (0.5%, 0.75%, and 1.0%) by mass of asphalt cement. The performance of modified asphalt samples has been studied and compared with an unmodified asphalt binder. The penetration, softening point and ductility were carried out to evaluate the influence of adding waste PET to asphalt on binder characteristics, binder stiffness at different temperatures also studied and all markedly improved. The results show that adding PETW has a significant effect on the rheological behavior and binder stiffness in high temperatures. This study indicates that waste PET has enhanced asphalt properties to minimize the paving costs and reduce solid waste environmental problems.

Keywords

Asphalt; Moifier; Polyethylene terephthalate waste; Physical properties

Introduction

Asphalt concrete mixture has been an important construction material for highways and airfield pavements [1-3]. It consists of mineral aggregate in a combination with bituminous binder (bitumen). Bitumen is an organic mixture forming from various chemical compounds and it is a very resistive material but when it exposed to different weather condition such as heat, oxygen and UV light the chemical structures and physical properties will be change, which is called aging [3]. Also increasing the number and weight of vehicles which passes on roads cause greater damages as a result, the most common distortions are rutting, decreased skid resistance and surface cracks [4]. That led to persistent need to improve the specification of asphalt pavement, using modified asphalt has played an important role to reduce pavement problems by improving thermal and physical properties which affected on the final performance of the mixture [5]. The first patent registered of asphalt modification by adding polymers goes back to 1843, while the first serious utilization of polymers in modification of bituminous mixtures in the 1990s [6]. Today there are several types of asphalt mixtures use for different purposes, and prepared by adding different modifications [7]. But utilizing of polymers in asphalt modification is relatively costly for paving roads [8]. So, using of waste materials in asphalt improvement (as a polymer additive) would be beneficial to enhance the properties of asphalt pavement, thus will increase of pavement life and decreasing the environmental pollution also [9,10]. The increasing of pavement life not only effect on maintenance intervals and costs but also help to save the energy used for maintenance which mean create sustainable pavements [9]. Environmental and climate protection became the focus of public attention, so the road construction industry must aim to be more sustainable in order to aid in tackling climatic change [11]. From the other side, it is important to note that not all of the waste material is suitable to use for asphalt improvement [12]. Polyethylene terephthalate (PET) the majority plastic bottles are made from. It becomes waste after a few times from purchase, thus it is considered as a real problem because the chemical recycling of PET is costly [13]. Hence, chemical recycling cannot be the perfect process to predomination on the crisis which arises from huge amount of PET waste [4]. Consequently, use PET as a combined modifier in asphalt mixture considered rational and efficient way to solve this problem. Previous studies have shown that using PET in concrete mixes can improve the rutting resistance [6]. Another study stated that the development of technology allows using recycle materials to increase stiffness, durability and enhance appearance [14]. On the other hand, utilization of (1.18 mm) PET size effect on rutting resistance and stiffness of bituminous mixture and produced lower binder drain down [9]. The researchers also reported there is a marked increase in softening point and viscosity in recycled PET modified bitumen [15]. Previous study also demonstrated that higher stability was obtained by adding 0.2% to 0.8% of PET [16]. The main objective of this study was to characterize the physical properties of bituminous mixture which prepared by adding different percentage of PET waste, consequently determining the optimum amount of the waste, which is required to improve the asphalt binder.

Materials and Experimental Methods

Bituminous material

Local asphalt cement produced by AL-Nasiriya Refinery in DHIQAR_IRAQ (350 km South of Baghdad) is used. The binder was 40/50 penetration grade, this grade is the most popular asphalt binder used in highway industry in Iraq. Its physical properties are presented in Table 1.

| Properties | Methods | Values |

|---|---|---|

| Penetration (25°C, 100 g) |

ASTM:D-5 | 48 (0.1mm) |

| Softening point (ring and ball) | ASTM:D-36 | 56 |

| Ductility at 25°C |

ASTM:D-113 | >100 cm |

| Viscosity at 135°C (mPa s) |

ASTM:D-4402 | -- |

Table 1: Physical properties of asphalt binder.

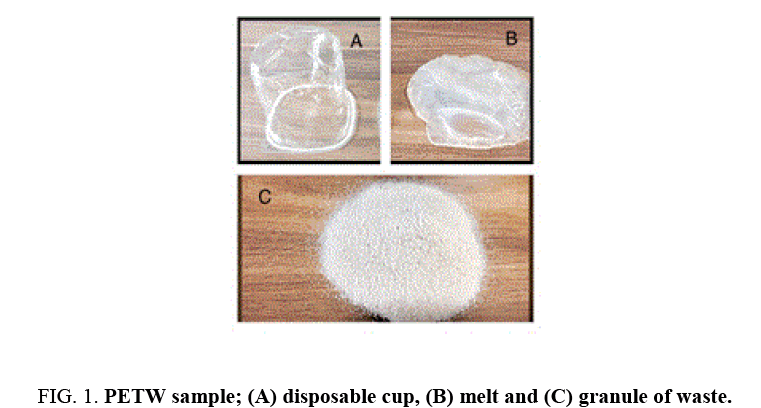

Polyethylene terephthalate

In this research work waste PET has been used as additives, its main properties are shown in Table 2. PET was collected from post-consumer, washed and dried. After that was melted and grinded by grinder machine. The granule PET particles were sieved; the sieve analyses indicated that 61% of PET passed through 0.300 mm sieve, 19% through 0.425 mm sieve and 19.6% through 0.600 mm sieve (Figure 1). In this study three different percentage of granule PET were used, which was (0.5%, 0.7%, 1.0%) by weight of asphalt binder.

| Density | Thermal conductivity | Melting point |

|---|---|---|

| 1370 kg/m3 | 0.15 to 0.24 W m-1 K-1 | 255°C |

Table 2: Physical properties of waste PET.

Samples preparation

Asphalt binder was heated to a temperature about (160 ± 10)°C to become more viscose [2], the ratios designed of PET granules added to the binder gradually to prevent the formation of conglomerates, by the method of wet process (two different methods using to add polymers in asphalt mixture, wet and dry methods. In the wet method process, the additives are added to the asphalt cement before mixing with aggregate particles. In the dry method, the polymer mixed with the aggregate before adding asphalt). The modifier asphalt was prepared by using high speed shear mixer (RH basic 2 type magnetic stirrer from IKA, Germany, speed 2000 rpm) at a temperature about 160°C-170°C for 2 h to uniformly disperse PET in binder and get homogenous blend [17].

Characterization

Samples was characterized by using of standard physical tests depend on the Asphalt Institute Manual (MS-17) to evaluate the influence of adding PET to asphalt on binder characteristics. The penetration of modified asphalt was measured according to ASTM D-5, ''Standard Test Method for Penetration of Bituminous Materials" (temperature, load and time are 25ºC, 100 g and 5 sec respectively). Softening point was measured by ASTM D-36, "Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus)". The ductility at 25°C for asphalt cement was tested according to ASTM D-113, "Standard Test Method for Ductility of Bituminous Materials" (at 25°C and with speed of 5 cm/min).

Temperature susceptibility of asphalt cement is conducted by determining the penetration softening point relationship using penetration index equation (PI) and stiffness of asphalt binder is measured by using Van der Poel’s nomograph. The Fourier Transform Infrared (FT-IR) analyses were recorded from Shimadzu Corporation, Japan. Scans were taken in the range 3600 cm-1 to 400 cm-1. Measurements were made at University of Kufa, faculty of Pharmacy laboratory.

Results and Discussion

Physical properties

The addition of PET to the asphalt binder was instigated the influences on physical properties as following:

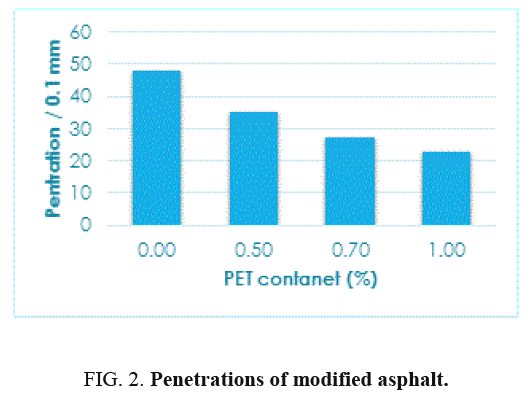

Penetration: The penetration test of bitumen is the representation adhesion and measures the consistency of bitumen [17]. Figure 2 shows the relationship between the penetration values and waste PET content, and illustrated the decreasing of penetration value with increasing of PET percentage because of the molecular components in asphalt (aliphatic, cyclic, and aromatic) will be reduce their influence by the effect of physical absorption when the polymer will be added and harder consistency of (PET-asphalt) binder [18].

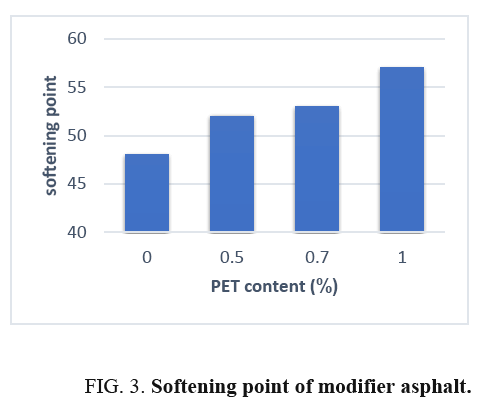

Softening point: The softening point is the temperature which the bitumen changes from the solid state to the fluid state during an increase in temperature with the presence of designer external force. Figure 3 shows the relationship between softening point of modified binders and PET contents. The changes in softening point indicate that achieved improvement in temperature susceptibility of the modified bitumen due to adding polymer and it will be increase with the increasing of PET content. At the softening point, asphalt is likely to show bleeding on the hot road surface under heavy traffic. For hot climates, asphalt with higher softening point is preferred, thus, binder with high temperature stability to reduce its tendency to soften in hot weather [15].

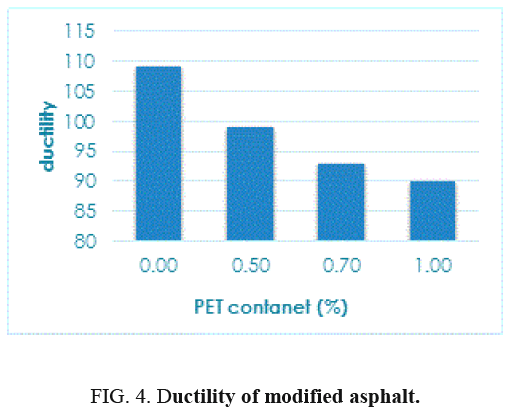

Ductility: Ductility is usually used to measuring the distance to which it will elongate before breaking when tow ends of a briquette specimen of the material are pall apart at a specified speed and temperature, and use to evaluation of lowtemperature anti-cracking performance of asphalt binder. Figure 4 shows the change in ductility value of binder and PET contents. The additive reduction in ductility at 25°C is due to stiffening of the asphalt binder by adding of PET [19].

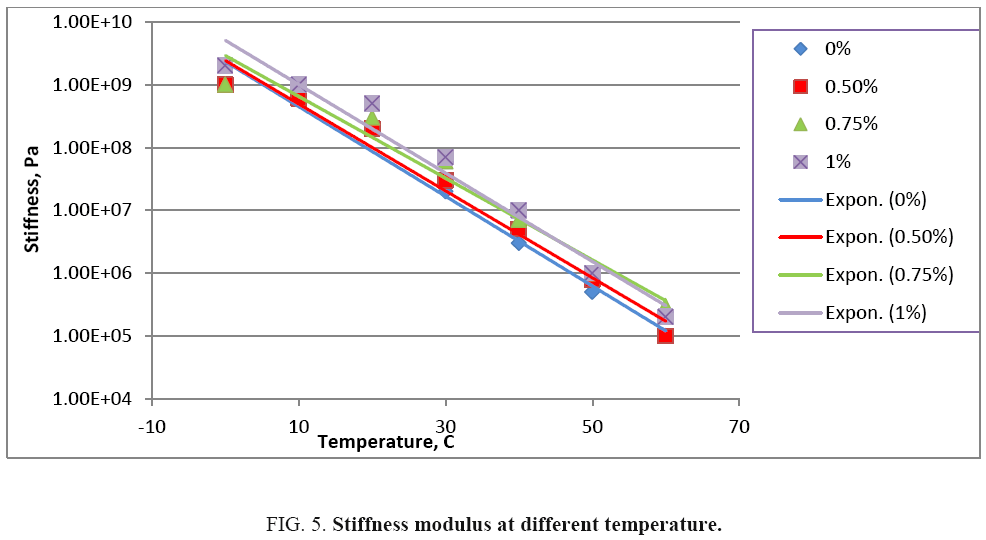

Stiffness: Binder stiffness has been determined from Van der Poel’s nomograph [20] for a number of variables:

One binder type (grade 40-50): Time of loading was 0.02 sec which is approximately corresponded to traffic speed of 50 Km/h. Temperature range from 0°C to 60°C.

Three PET contents: 0.50%, 0.75% and 1.00%.

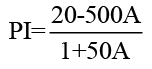

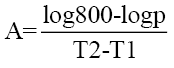

Temperature susceptibility was measured by using penetration index (PI) relationship which is an approach to characterize the effect of temperature on asphalt cement. This index is based on penetration plus softening point as follow:

Where, P: Penetration value; T2: Ring and Ball softening point; and T1: 25°C.

Higher value of P.I indicates lower temperature susceptibility [21]. Table 3 illustrates the P.I value for modified and unmodified asphalt cement samples.

| PET content % | T r & b, °C | P. I |

|---|---|---|

| 0 | 48 | -1.79 |

| 0.5 | 52 | -1.45 |

| 0.75 | 53 | -1.72 |

| 1 | 53 | -2 |

Table 3: The P.I value for modified and unmodified asphalt cement.

Figure 5 Illustrates the stiffness value for different waste PET content of asphalt binders at different temperature at the same loading time. From this Figure 5 it can be obtained that in hot climate, the adding of waste PET had resulted in mixtures with sufficient stiffness to avoid permanent deformation under traffic loading [20].

FT-IR spectroscopy

The IR spectrum for both virgin and modified asphalt binder was measured. Figure 5a (for raw asphalt binder) has peaks in the region 3437 cm-1-2924 cm-1, 2852 cm-1, 1616 cm-1, 145 8 cm-1, 1375 cm-1 and 1375 cm-1 which are represent to amine N-H, aliphatic and aromatic C-H stretching vibration bands, amines C-N, and C-H bending vibration band, respectively [5,10]. Figure 5b shows the infrared spectra after modification. FT-IR spectrum bands of amorphous PET have been assigned as follows, 3057 cm-1-2950 cm-1 to aromatic and aliphatic C-H bond stretching, 1722 cm-1-1504 cm-1 to the ester carbonyl bond stretching, 1450 cm-1-1350 cm-1 to bending and wagging vibrational modes of the ethylene glycol segment, 1260 cm-1-1247 cm-1 to the C-O for ester group, 1097 cm-1 to the methylene group and aromatic bands in-plane/out-plane bending at 1018 cm-1 and 727 cm-1 [22], and all bands for asphalt binder before modification are still appears, so it can be concluded that asphalt has no obvious changes in functional groups before and after suggesting that the modification of asphalt with PET is a physical process [23].

Conclusion

This study focused on a laboratory assessment of using waste PET as a binder modified and it was presented according to the conventional properties. Results show:

1. An obvious increase stiffness of the modified binder in high temperatures which means declined their temperature susceptibility. Characterization summaries that, modification using additives able to improve the high temperature stability performance and has not adversely affected in low temperature.

2. Penetration index values indicated that waste PET reduced the temperature susceptibility of asphalt and the optimum amount was 0.75% PET content which give higher P.I value.

3. Penetration at 25°C will decrease as PET content increases, which indicates improve in shear resistance in medium to high temperatures.

4. The addition of PET kept the ductility values close from the minimum range of ASTM specifications of 100 cm.

5. Softening point for all modified sample was increased hence, resistance to deformation.

References

- SunL, XinX, RenJ. Asphalt modification using nano-materials and polymers composite considering high and low temperature performance.Constr Build Mater. 2017;133:358-66.

- BaghaeeMoghaddamT, KarimMR, SyammaunT. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr Build Mater. 2012;34:236-42.

- El-ShafieM, IbrahimIM, Abd El RahmanMM. The addition effects of macro and nano clay on the performance of asphalt binder. Egypt J Pet. 2012;21:149-54.

- BaghaeeMoghaddam T, SoltaniM, KarimMR. Experimental characterization of rutting performance of polyethylene terephthalate modified asphalt mixtures under static and dynamic loads.Constr Build Mater. 2014;65:487-94.

- Laboratory Study on Nano Clay Modified Asphalt Pavement. 2016.

- AhmadiniaE, ZargarM, KarimMR, et al. Performance evaluation of utilization of waste polyethylene terephthalate (PET) in stone mastic asphalt.Constr Build Mater. 2012;36:984-89.

- Hellwig S, KarriA. Comparing rubber modified asphalt to conventional asphalt assessment of Trafikverket’s road survey tool. 2015.

- Te ChiuC, LuLC. A laboratory study on stone matrix asphalt using ground tire rubber.Constr Build Mater. 2007;21:1027-33.

- Sojobi AO, NwobodoSE, AladegboyeOJ, et al.Recycling of polyethylene terephthalate (PET) plastic bottle wastes in bituminous asphaltic concrete. Cogent Eng. 2016;3:1133480.

- FangA, YuR, ZhangY, et al. Combined modification of asphalt with polyethylene packaging waste and organophilicmontmorillonite. Polym Test. 2012;31:276-81.

- Hessing C, Thesseling B, Alexander W. A sustainable maintenance method for cracked pavements using polyester asphalt reinforcement. Increase pavement life, reduce maintenance and create sustainable pavements.

- IsmailZZ, AL-HashmiEA. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008;28:2041-7.

- LiY, WhiteDJ, Lee PeytonR. Composite material from fly ash and post-consumer PET.ResourConservRecycl. 1998;24:87-93.

- TamVWY, TamCM. A review on the viable technology for construction waste recycling. ResourConservRecycl. 2006;47:209-21.

- MahrezA,KarimMR. Rheological Evaluation of Bituminous Binder Modified With Waste Plastic Material. 2010.

- SoltaniM, MoghaddamTB, KarimMR, et al. Analysis of fatigue properties of unmodified and polyethylene terephthalate modified asphalt mixtures using response surface methodology.Eng Fail Anal. 2015;58:238-48.

- NassarM, KabelKI, IbrahimIM. Evaluation of the effect of waste polystyrene on performance of asphalt binder. ARPN J Sci Technol. 2012;2:927-35.

- Al-jumailiMAH. Modification of Asphalt Cement Properties and Chemical Properties by Polyprolene and Cellulose Additives.2016;2:33-9.

- GolestaniB, NamBH, MoghadasNejadF, et al.Nanoclay application to asphalt concrete: Characterization of polymer and linear nanocomposite-modified asphalt binder and mixture.Constr Build Mater. 2015;91:32-8.

- Airey GA, Dan G. Rheological characteristics of polymer modified and aged bitumens. PhD thesis, University of Nottingham. 1997.

- Al-HadidyAI, Yi-qiuT. Effect of polyethylene on life of flexible pavements.Constr Build Mater.2009;23:1456-64.

- ChenZ. The crystallization of poly ethylene terephthalate. Thermal Analysis and FT-IR Spectroscopy.2012;219:2012.

- Nasrazadani SN, Mielke D, Springfield T, et al. Practical Applications of FT-IR to Characterize Paving Materials.2010;pp:1-5.