Original Article

, Volume: 11( 2)Formation of Deep-Subwavelength Nanohole Arrays Embedded in Laser-Induced Nanoripples in Liquid Environments

- *Correspondence:

- Khuat V

Department of Software Engineering, Faculty of Information Technology

Le Quy Don Technical University, No.236, Hoang Quoc Viet Street, Hanoi, 7EN-248, Vietnam

Tel: +841673326268

E-mail: thanhvankhuat2000@gmail.com

Received: Aug 09, 2017; Accepted: Oct 16, 2017; Published: Oct 23, 2017

Citation: Khuat V. Formation of Deep-Subwavelength Nanohole Arrays Embedded in Laser-Induced Nanoripples in Liquid Environments. Nano Sci Nano Technol. 2017;11(2):120

Abstract

Deep-subwavelength nanohole arrays embedded in nanoripples are observed in silicon carbide surface after irradiation of an 800-nm femtosecond laser in water and alcohol environment. The period of the nanoripples is about 500 nm. The diameter of the holes ranges from 10-30 nm. The effects of the liquid medium to the formation of the nanohole arrays are discussed. Under irradiation in alcohol, more nanohole arrays could be formed, and the nanoholes are more uniform in size. Moreover, we investigate the influence of the laser scanning speed on the nanohole arrays fabricated under irradiation in alcohol.

Keywords

Nanostructure fabrication; Laser materials processing; Semiconductor materials; Ultrafast lasers

Introduction

Laser micromachining has several prominent advantages over conventional methods, such as noncontact processing, fast removal rates and mask less processing. In particular, femtosecond laser processing has recently emerged as an enabling tool for material processing and has promised a wide variety of intriguing applications, owing to its ability to suppress the heat-affected zone, perform sub-diffraction-limit processing, and carry out true 3D selective modifications [1-5].

The generation of nanostructures by femtosecond laser, of which the period could be much smaller than the incident laser wavelength, is one of the very interesting phenomena that have drawn great attention of researchers [6-9]. Laser-induced nanoripples could be classified into two types, namely, near-wavelength nanoripples and deep-wavelength nanoripples. The former, whose period is close to the incident laser wavelength, is widely accepted as a result of the interference of the incident light wave and the surface scatter wave [10-13]. According to this theory, the period of the ripples could be controlled by varying the incident angle. The latter, whose period is much smaller than incident laser wavelength, is believed to be generated by the interference of the incident light wave and the laser-induced surface plasma wave [14,15]. The presence of nanoripples on a surface would change how the laser interacts with the material, since the nanoripples can act as a grating which could efficiently couple incident light wave and convert it into plasma wave. Specifically, since the width of the laser-induced nanogroove is about 10-50 nm [16], which is much smaller than the incident laser wavelength, light waves cannot propagate in such a small structure because of the diffraction limit. Therefore, it can be expected that surface plasmon polaritons (SPPs) can be generated and confined in the nanogroove, which would induce much smaller nanostructures on the surface of the material. In addition, it has been reported that liquids could bring several advantages for the laser ablation, such as higher efficiency and cleaner ablation. Several publications have addressed the effects of liquid medium, such as water and alcohol to the efficiency of laser ablation [17-21]. And it is expected that clearer nanoripples pattern could be achieved as the laser irradiation is conducted in liquid environment. Therefore, the impact of laser-induced nanoripples on the interaction of the incident laser and the material would be more significant, leading to the formation of much smaller structures. However, most of the available publications only focused on characterizing the morphologies and the formation mechanism of the nanoripples. Few studies have been reported about the formation of deep-subwavelength structures formed in nanoripples. Recently, we reported the formation of deep-subwavelength nanohole arrays embedded in nanoripples fabricated by an 800-nm femtosecond laser [22], in which the formation of the nanohole arrays was attributed to the formation of the channel plasmon polaritons (CPPs) in the nanogrooves associated to the nanoripples.

In this work, it is observed that the nanohole arrays could also be formed in nanoripples fabricated with the irradiation of an 800-nm femtosecond laser in an alcohol environment. The diameter of the holes ranges from 10-30 nm. Note that the nanoholes are much smaller than the wavelength of the incident laser, which is 800 nm. The structure is different with the classical laser-induced nanostructures in two aspects. For one thing, the size is in order of tens nano-meter instead of hundreds of nano-meters. For the other thing, the structures can only be formed under irradiation under irradiation in liquids environment. Specifically, under irradiation in alcohol, more nanohole arrays are formed, and the holes are more uniform, as compared to those generated under irradiation in water. This method can be used for manufacturing deep-subwavelength nanostructures using laser irradiation. The nanohole arrays are characterized using a scanning electron microscope (SEM). In addition, we investigate the influence of the laser scanning speed to the deep-subwavelength nanohole arrays.

Experimental Details

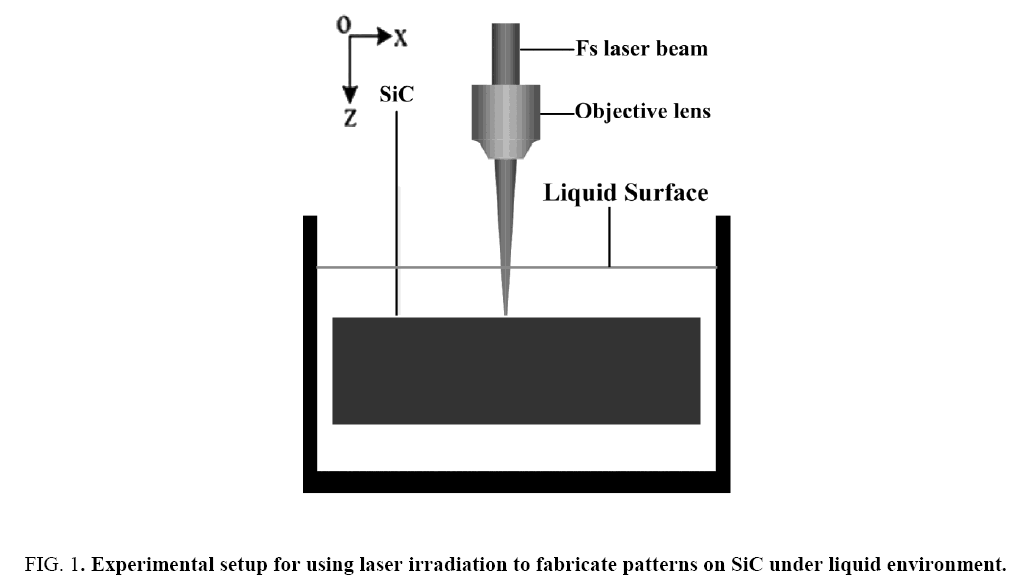

The experimental setup as shown in Figure 1 consists of a femtosecond laser source, an attenuator, a neutral density filter, a mechanical shutter, a xyz movable stage, a computer, and a CCD camera. The laser used was an amplified Ti: Sapphire femtosecond laser system (Coherent Inc., USA) with pulse duration of 150 fs, wavelength of 800 nm, and repetition rate of 1 kHz.

Figure 1: Experimental setup for using laser irradiation to fabricate patterns on SiC under liquid environment.

The attenuator provides a convenient way to adjust the laser energy, and the mechanical shutter was employed to control the access of the laser beam. The movable stage, on which the SiC sample can be mounted, is controlled by a computer program and allows us to fabricate structures on the patterns with high precision. The CCD camera is connected to a computer for clear online observation of the SiC pattern surface during fabrication. A 10× microscope objective with numerical aperture (NA) of 0.3 is employed to focus laser onto the surface of the pattern. The diameter of the spot on the pattern is about 10 μm.

In our experiments, a 6H-SiC pattern 350 μm in thickness was used. First, it was cleaned in acetone and de-ionized water with an ultrasonic field for 10 min each; then it was immersed in a small liquids pool before being mounted on the movable stage. Water and alcohol were used in our experiments. The laser beam was focused onto the pattern via an optical microscope objective lens. During fabrication, the surface of the SiC pattern could be seen either via optical microscope or on the computer screen connected to the CCD camera. After laser irradiation, an SEM was employed to study the morphology of the structures on the SiC surface.

Results and Discussion

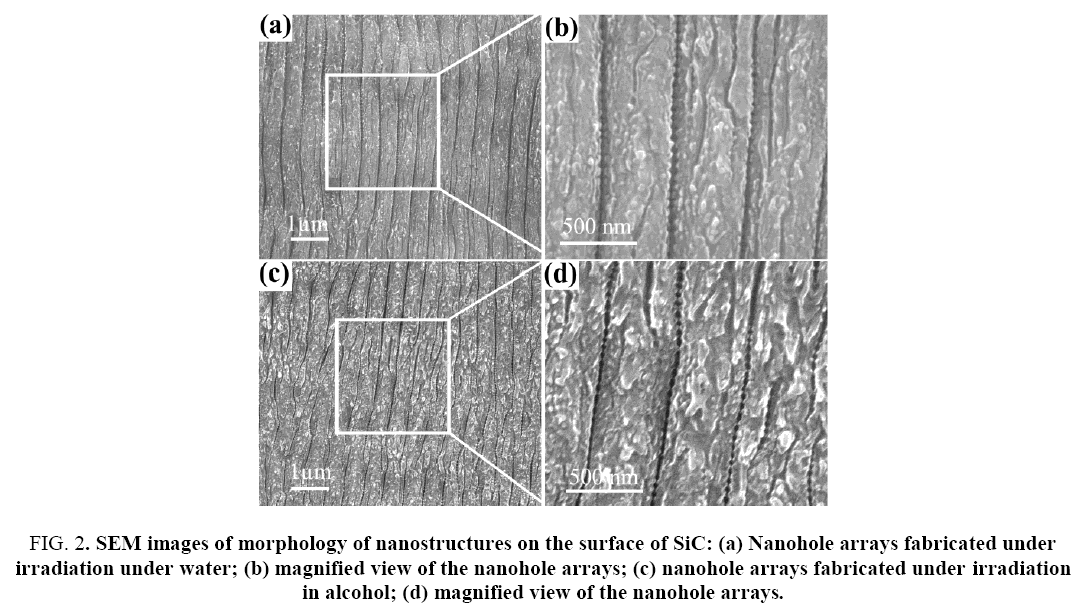

Figure 2 shows the morphologies of the deep-subwavelength nanohole arrays embedded in the nanoripples fabricated by the irradiation of an 800-nm femtosecond laser in water and alcohol environment, respectively. The laser average power and scanning speed were 10 mW and 1500 μm/s, respectively. For a same dose of laser irradiation, though deep-subwavelength nanohole arrays were formed in both cases, there were some differences between the two. First, under irradiation in water, nanohole arrays are only be formed in some specific places as shown in Figure 2(a) and (b). Meanwhile, under irradiation in alcohol, the nanohole arrays are formed in most of the nanogrooves as shown in Figure 2(c) and (d). Second, the nanohole arrays fabricated under irradiation in alcohol are more uniform and slightly smaller than those fabricated in water. The period of the nanoripples is about 500 nm; the nanoripples are perpendicular to the laser polarization direction. The period of the nanohole arrays is about 60 nm, and the diameter ranges from 10-30 nm. The laser scanning velocity was 1500 μm/s corresponding to about 80% overlap between two neighbor laser pulses.

Figure 2: SEM images of morphology of nanostructures on the surface of SiC: (a) Nanohole arrays fabricated under irradiation under water; (b) magnified view of the nanohole arrays; (c) nanohole arrays fabricated under irradiation in alcohol; (d) magnified view of the nanohole arrays.

The formation of nano-ripples can be attributed to the interference between the incident laser wave and the laser-induced surface plasma wave [13]. The formation of deep-subwavelength nanohole arrays can be attributed to the guiding effect of the CPPs on the nanogrooves associated with the nanoripples [22]. Note that the geometry of the nanogroove has a great impact on the formation and the propagation of the CPPs [23-28]. In an earlier publication, we concluded that clear nanogrooves are difficult to achieve under irradiation in ambient air because the debris redeposited on the surface during laser treatment could scatter the incident light, severely damaging the structure of the nanopatterns on the surface; therefore, nanohole arrays cannot be formed. Clearer nanogrooves, which can support the formation and propagation of CPPs, can be achieved under irradiation in liquids. Once a nanogroove is formed on the surface, CPPs can be formed as the next laser pulse reaches the surface and be converted into CPPs. So the formation of the nanohole arrays is largely dependent on two factors: the formation of a clear nanogroove and the efficiency of light being converted into CPPs. Because of its outstanding flow and volatilization properties, alcohol could bring several advantages, as compared to water, for the formation of deep-subwavelength nanohole arrays. For one thing, the ablation debris could be carried away right after the ablation. Therefore, the nanogrooves of nanoripples fabricated in alcohol are cleaned simultaneously during irradiation, leading to the formation and propagation of CPPs in the nanogroove. As a result, the nanohole arrays are easier to be formed. For another, under irradiation in alcohol, efficiency of incident laser light being coupled in CPPs is expected to be higher than that under irradiation in water because bubbles generated during irradiation which would scatter incident light, can be carried away quickly. It is well-known that bubbles always accompany with laser irradiation in liquid environment. As irradiated with multiple pulses, the bubbles can be formed as the first pulse reaches the targets, scattering the next pulse, thus, reducing the energy of the pulse as it reaches the nanogrooves. Therefore, deep-subwavelength nanohole arrays are expected to be easier to form.

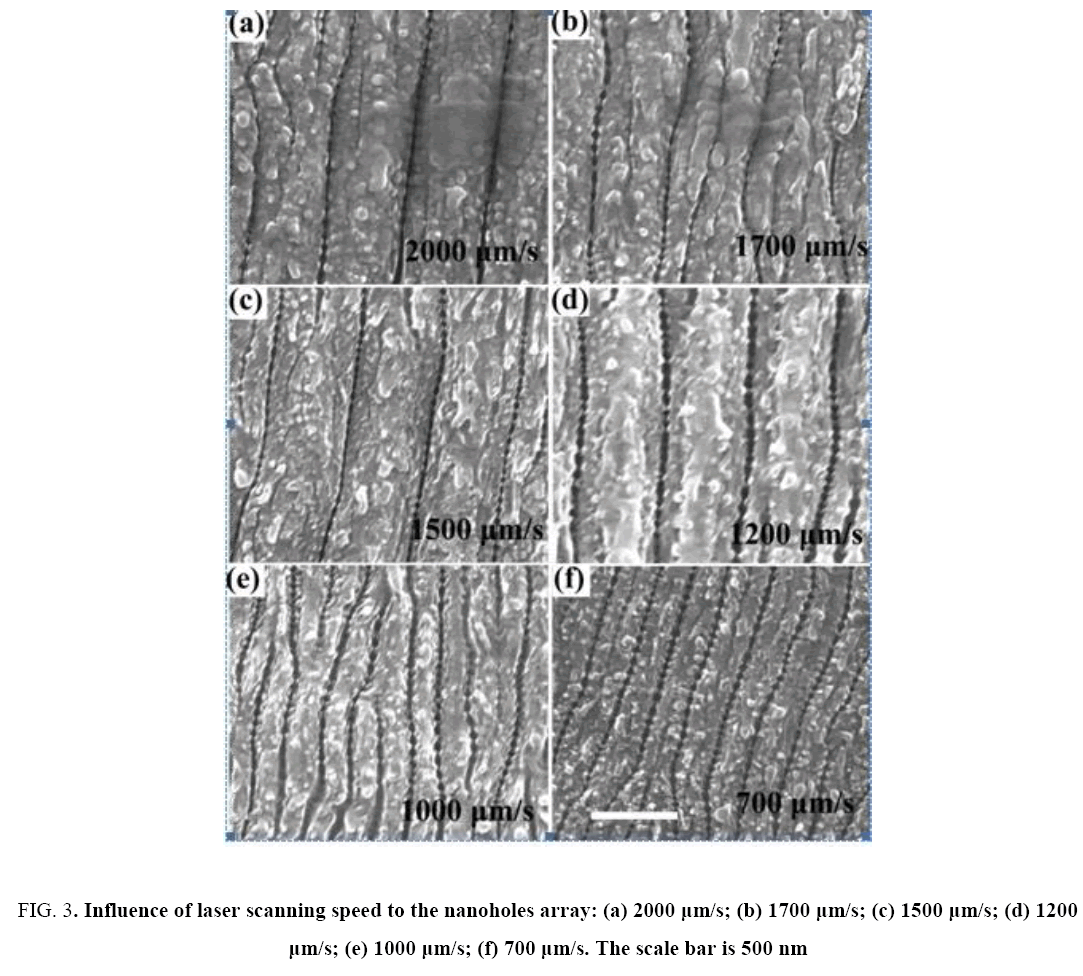

Moreover, we also studied the influence of laser scanning speed on the deep-subwavelength nanohole arrays. Figure 3 shows the morphologies of the nanohole arrays as different scanning speeds were applied, while the laser average power was fixed at 10 mW. As the scanning speed decreases, the period of the nanoripples decreases and the nanogrooves become wider. Accordingly, the size of the nanoholes becomes larger. This is because of the pulse accumulating effect. As the scanning speed decreases, the average pulses number on unit area of the SiC samples increase. This also means that the laser energy accumulated on unit area of the SiC pattern increases. As a result, the period of the nanoripples decreases and the nanogrooves are deepened because of the field distribution effect and grating assisted surface Plasmon laser coupling [15]. At the meantime, as the laser scanning speed decreases, larger overlapping area between two neighbour laser pulses is expected, and CPPs is more likely to be generated and propagate inside the nanogroove. Therefore, more nanoholes arrays could be formed.

Figure 3: Influence of laser scanning speed to the nanoholes array: (a) 2000 μm/s; (b) 1700 μm/s; (c) 1500 μm/s; (d) 1200 μm/s; (e) 1000 μm/s; (f) 700 μm/s. The scale bar is 500 nm

Conclusion

In conclusion, we fabricated deep-subwavelength nanohole arrays embedded in nanoripples in SiC in water and alcohol, respectively, by the irradiation of an 800-nm femtosecond laser. The period of the nanoripples was about 500 nm. The ripples were perpendicular to the polarization direction of the incident laser. The size of the nanoholes ranged from 10-30 nm, and the period was about 60 nm. Nanoripples formation can be attributed to interference of the incident laser and the laser-induced surface plasma wave. Deep-subwavelength nanohole arrays formation can be attributed to the guiding effect of CPPs in the nanogrooves associated with the nanoripples. Under irradiation in alcohol, more hole arrays were formed and more uniform in size. This is maybe because of the flow and volatilization of alcohol which were helpful for the formation of clearer nanogrooves pattern. Additionally, we investigated the influence of the laser scanning speed on the nanohole arrays.

Acknowledgment

The authors sincerely thank Ms. Dai at International Center for Dielectric Research (ICDR) in Xi’an Jiaotong University for the support of SEM and EDS measurements.

References

- Gattass RR, Mazur E. Femtosecond laser micromachining in transparent materials. Nat photonics. 2008;2(4):219-225.

- Lin J, Yingxin X, Zhiwei F, et al.Fabrication of high-Q lithium niobatemicroresonators using femtosecond lasermicromachining. Sci Rep. 2015;58072.

- Chen F, Aldana JR. Optical waveguides in crystalline dielectric materials produced by femtosecond?laser micromachining Laser Photonics Rev. 2014:8:251-75.

- Bachus KJ, Mats L, Choi HW, et al.Fabrication of patterned super-hydrophobic/hydrophilic substrates by laser micromachining for small volume deposition and droplet-based fluorescenceACS Appl Mater Inter. 2017;9(8):7629-7636.

- Chen T, Si J, Hou X, et al. Applied physics specialties.J Appl Phys. 110, 073106-1-4, 2011.

- Khuat V, Chen T, Gao B, et al. Uniform nano-ripples on the sidewall of silicon carbide micro-hole fabricated by femtosecond laser irradiation and acid etching. ApplPhysLett. 2014;104(24):241907.

- Qu S, Zhang Y, Li H, et al. Nanosecond nonlinear absorption in Au and Ag nanoparticles precipitated glasses induced by a femtosecond laser. Opt Mater.2006;28(3):259-65.

- Bhardwaj VR, Simova E, Rajeev PP, et al. Optically produced arrays of planar nanostructures inside fused silica. Phys Rev Let. 2006;96(5):057404.

- Shimotsuma Y, Kazansky PG, Qiu J, et al. Self-organized nanogratings in glass irradiated by ultrashort light pulses. Phys Rev Let. 2003;91(24):247405.

- Zheng Y, An, Z,Smyrek P, et al. Laser interference patterning and laser-induced periodic surface structure formation on metallic substrates. InManipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO). IEEE International Conference. 2016:159-163.

- Wagner R, GottmannJ.Sub-wavelength ripple formation on various materials induced by tightly focused femtosecond laser radiation. In Journal of Physics: Conference Series. IOP Publishing. 2007;59(1):333).

- Hou S, Huo Y, Xiong P, et al.Formation of long-and short-periodic nanoripples on stainless steel irradiated by femtosecond laser pulses. D Appl Phys. 2011;44(50):505401.

- Young JF, Preston JS, Van Driel HM, et al. Laser-induced periodic surface structure. II. Experiments on Ge, Si, Al, and brass. Phys Rev B. 1983;27(2):1155.

- Huang M, Zhao F, Cheng Y, et al. Mechanisms of ultrafast laser-induced deep-subwavelength gratings on graphite and diamond. Phys Rev B. 2009;79(12):125436.

- Huang M, Zhao F, Cheng Y, et al. Origin of laser-induced near-subwavelength ripples: interference between surface plasmons and incident laser. Acs Nano. 2009;3(12):4062-70.

- Buividas R, Rosa L, Sliupas R, et al. Mechanism of fine ripple formation on surfaces of (semi) transparent materials via a half-wavelength cavity feedback. Nanotechnology. 2011;22(5):055304.

- Daminelli G, Kruger J, Kautek W.Femtosecond laser interaction with silicon under water confinement. Thin Solid Films. 2004;467(1):334-341.

- Kruusing A. Underwater and water-assisted laser processing: Part 2—Etching, cutting and rarely used methods. Opt. Laser. Eng. 2004;41(2):329-52.

- Li C, Shi X, Si J. et al. Alcohol-assisted photoetching of silicon carbide with a femtosecond laser. Opt Commun. 2009;282(1):78-80.

- Wee LM, Khoong LE, Tan CW, et al. Development of a water-jet assisted underwater laser cutting process.Int J Appl Ceram Tec. 8(6), 1263-1276(2011).

- Tan D, Zhou S, Qiu J, et al.Preparation of functional nanomaterials with femtosecond laser ablation in solution. PhotochPhotobio C. 2013;17:50-68.

- Khuat V, Si J, Chen T, et al. Deep-subwavelengthnanohole arrays embedded in nanoripples fabricated by femtosecond laser irradiation. Opt Lett. 2015;40(2):209-212.

- Bozhevolnyi SI, Volkov VS, Devaux E, et al.Channel plasmon-polariton guiding by subwavelength metal grooves. Phys Rev Let. 2005;95(4):046802.

- Bozhevolnyi SI, Volkov VS, Devaux E, et al. Channel plasmon subwavelength waveguide components including interferometers and ring resonators. Nature. 2006;440(7083):508-11.

- Pile DF, Gramotnev DK,Channel plasmon–polariton in a triangular groove on a metal surface. Optics Letters. Opt Lett. 2004;29(10):1069-71.

- Makin VS, Logacheva EI, Makin RS.Localized surface plasmon polaritons and nonlinear overcoming of the diffraction optical limit. Opt Spectrosc. 2016;120(4):610-4.

- Makin VS, Pestov YI,Makin RS. Surface nanogratings of abnormal orientation in universal polariton model of laser-induced damage of condensed media. In Journal of Physics: Conference Series. IOP Publishing. 2016;737(1):012014.

- Wang L, Cao XW, Chao LV, et al. Formation of deep-subwavelength structures on organic materials by femtosecond laser ablation. IEEE Journal of Quantum Electronics. 2017:99.