Original Article

, Volume: 14( 1)Extraction of Each Part of Chamaecyparis obtusa Using Supercritical CO2

- *Correspondence:

- Byun SY, Head, Cosmetic Science Major, Applied Biotechnology Department, Graduate School and Director, Cosmetic Business R&D Center, Ajou University, Suwon-16499, South Korea, Tel: +82-31-219-2451; E-mail: sybyun@ajou.ac.kr

Received: March 16, 2018; Accepted: April 10, 2018; Published: April 16, 2018

Citation: Kwak BM, Lee DS, Ju YW, et al. Extraction of Each Part of Chamaecyparis obtusa Using Supercritical CO2. Nat Prod Ind J. 2018;14(1):117.

Abstract

In this study, extraction of Chamaecyparis obtusa oil from leaf, wood, bark, cone using supercritical CO2 was carried out. The highest yield was obtained from leaves. The supercritical CO2 extraction of C. obtusa was influenced by temperature. When the temperature increased from 40℃ to 50℃ and 60℃, the yield increased. Among various parts of C. obtusa, the cone showed higher temperature dependency on extraction yield and rate than other parts. The color of oils extracted was different. The oil color from leaves was deep green. The oil from wood was brown red. Oil colors from bark and cone were yellow and brown respectively.

Keywords

Supercritical fluid extraction; CO2; Chamaecyparis obtusa

Introduction

Phytoncides from Chamaecyparis obtusa has been reported to have many biological activities including antioxidant, antimicrobial activity, and NK cell activating activity [1,2]. However, there are not many evidences about the effects of phytoncide on the cardiovascular diseases [3]. There are many kind of secondary metabolism components from C. obtusa such as 66% kind of monoterpene and 25% sesqui-terpene. [4]. These compounds are attributed many physiological effects, such as antioxidant and anti-mutagenic activities [5]. In the measurement of generation of cytokine of MCP-1, IL-6 and IL-8 which is of inflammatory Cytokine of EoL-1 and THP-1 cells the leaf extract injected group showed significant decrease for EoL-1 and THP-1 in compare is on with that of mite Atopic dermatitis group [6]. Many methods are available to extract oils or lipids from C. obtusa. The conventional method of cold compression is used to produce C. obtusa extract with high quality however, the yield is too low [7]. The method using organic solvent is easy and fast. However, the purity is low and there is the risk of organic solvent residue. Supercritical fluid extraction (SFE) is a promising alternative method to replace conventional solvent extraction because the supercritical CO2 is nontoxic, nonexplosive, and easily removable from products. Recent years, SFE technology has been widely applied to wide area of industry, especially in pharmaceutical, nutraceutical and cosmetic industry. This method has several advantages over conventional extraction methods such as lower extraction temperature, lower degradation of heat-susceptible compounds. SFE has higher selectivity and easily adjust the selectivity by changing the pressure and temperature. Other advantages are it can get the high purity products, no-solvent residues because the extraction solvent commonly used is CO2 that is inert, non-toxic and low cost [8]. The supercritical fluid extraction will be widely used by replacing conventional methods for high quality products in many industrial areas [9]. In this study, we investigated the supercritical fluid extraction of different parts of C. obtusa and optimized various factors influencing extraction. Their yields of oil were also compared to yields extracted with organic solvent.

Material and Methods

Materials

Plant materials: The parts of Chamaecyparis obtusa (leaf, wood, bark, and cone) were obtained from a grove in Jangseong-gun, Jeollanam-do Korea. The raw material was powdered, dried to get the humidity less than 5%.

Instruments: Supercritical fluid extraction system MSFE0500R1 – SC Labs in Korea. Extraction tank volume was 2,000 ml; separation tank volume was 1,000 mL, CO2 recycler.

Methods

1.The extraction methods using organic solvent: 20 g the part of C. obtusa powder extracted in soxlhet system withhexane as solvent at 60°C for 10 hours. The extract was evaporated under reduced pressure; remove the organicsolvent by CO2 continuously for 1 hour. Centrifuge at the rate of 5000 rpm, collected the liquid oil, weigh anddetermine the general indices of C. obtusa oil.

2.Supercritical fluid extraction method: Put the powder into clothes pack, place into extraction tank. Set up theparameters of temperature, pressure, CO2 flow, and turn on the cooling system. When the set parameters wereachieved, open the valve to get liquid CO2 from containing tank flow through the cooling system and then pump upto get high pressure. CO2 was conducted through the heating part to increase temperature, at that time liquid CO2will transform to supercritical state and go to extraction tank. At the extraction tank (containing raw material), thetemperature and pressure are controlled to maintain the supercritical state of CO2 according to investigatedconditions. C. obtusa oil and other lipophilic components are dissolved in supercritical CO2 and extracted out of rawmaterials then flowed to reduced pressure part before going to separation tank. The temperature and pressure ofseparation tank was strictly controlled, at that time supercritical CO2 transforms to aerial state and lost the ability todissolve C. obtusa oil. The C. obtusa oil was precipitated and taken out by the sampling part. Aerial CO2 state wasconducted to condensation tank and cooled to get the liquid CO2 and then recycled for continuous extraction [9-11].

Results and Discussion

Extraction of each part of C. obtusa oil using organic solvent

Oils extracted by soxhlet extraction using organic solvent have been used in quality control or quantitative analysis of plant fats and oils. Organic solvent may be n-hexane, petroleum ether, chloroform [12]. In this study, we used the n-hexane to extract oils from various parts of C. obtusa. As shown in Table 1, different part of C. obtusa resulted different extraction yields. The highest yield was obtained from leaves. Some other studies reported the content of oil in leaf of C. obtusa in the range of 3-5%, [13]. Another different result by extraction was different colors. The color of each oil extracted was different. The oil color from leaves was deep green. The oil from wood was brown red. Oil colors from bark and cone were yellow and brown respectively.

| Raw material (g) | Extracted oil (g) | Yield (%, w/w) | |

|---|---|---|---|

| Leaf | 20 | 1.04 | 5.2 |

| Wood | 20 | 0.22 | 1.1 |

| Bark | 20 | 0.37 | 1.85 |

| Cone | 20 | 0.63 | 3.15 |

Table 1: The extraction of various parts from C. obtusa using n-hexane.

The supercritical CO2 extraction of C. obtusa

For supercritical extraction, the carbon dioxide was compressed to 350 bar which was in supercritical condition. The flow rate was 145 ml/min. For higher extraction rate, each parts of C. obtusa were ground to particles sized between 800 to 1,000 μm. The temperature effect on supercritical CO2 extraction was carried out. Extractions were made at different temperature 40°C, 50°C and 60°C. Results were monitored according to the time as shown in Table 2.

| Time (min) | Yield at different temperature (%) | ||

|---|---|---|---|

| 40°C | 50°C | 60°C | |

| 20 | 2.68 | 2.83 | 3.04 |

| 40 | 3.56 | 3.91 | 4.58 |

| 60 | 4.01 | 4.27 | 5.24 |

| 80 | 4.36 | 4.5 | 5.46 |

| 100 | 4.51 | 4.64 | 5.57 |

| 120 | 4.66 | 4.72 | 5.66 |

Table 2: The effect of temperature on supercritical CO2 extraction yield of leaves.

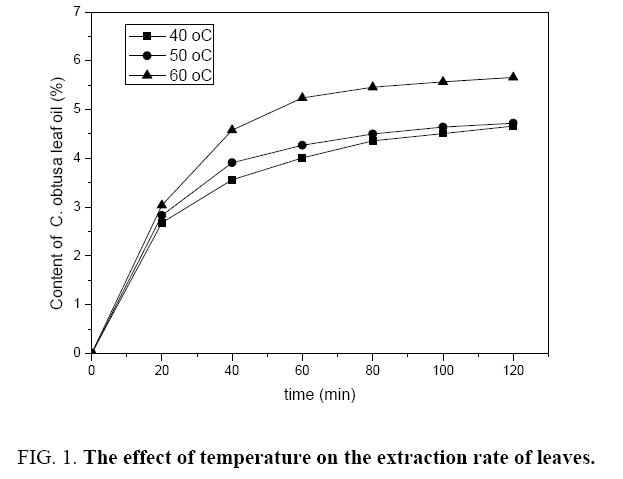

As shown in Table 2, the supercritical CO2 extraction of C. obtusa was influenced by temperature. Different temperature resulted different yield of oil extraction. When the temperature increased from 40°C to 50°C and 60°C, the yield increased. At 60°C, the yield was the highest. However, the yield from the above conditions was low, at 60°C and 120 minutes, the yield was 5.66%. In supercritical extraction, the change of temperature will change the density of supercritical CO2, thus change its solubility [14]. In this study, we determine the yield at 40°C, 50°C and 60°C. From the table, the yield was the highest at 60°C. The time dependent changes of yield could be used to determine the extraction rate as shown in Figure 1.

Other supercritical CO2 extractions were carried out with different parts of C. obtusa. With wood bark, same supercritical extractions were made at different temperature 40°C, 50°C and 60°C. Results were monitored according to the time as shown in Table 3.

| Time (min) | Yield at different temperature (%) | ||

|---|---|---|---|

| 40°C | 50°C | 60°C | |

| 20 | 0.33 | 0.54 | 0.59 |

| 40 | 0.7 | 0.97 | 0.99 |

| 60 | 1 | 1.11 | 1.19 |

| 80 | 1.16 | 1.18 | 1.27 |

| 100 | 1.21 | 1.22 | 1.3 |

| 120 | 1.25 | 1.26 | 1.33 |

Table 3: The effect of temperature on supercritical CO2 extraction yield of wood bark.

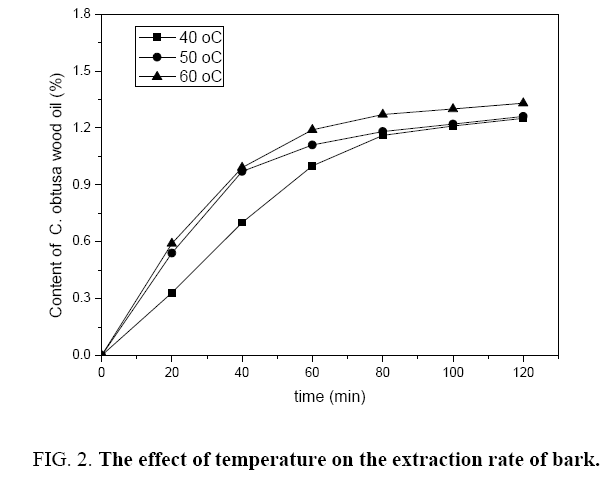

With wood bark, different temperature resulted different yield of oil extraction. When the temperature increased from 40°C to 50°C and 60°C, the yield increased. At 60°C, the yield was the highest as 1.3%. The time dependent changes of yield could be also used to determine the extraction rate as shown in Figure 2.

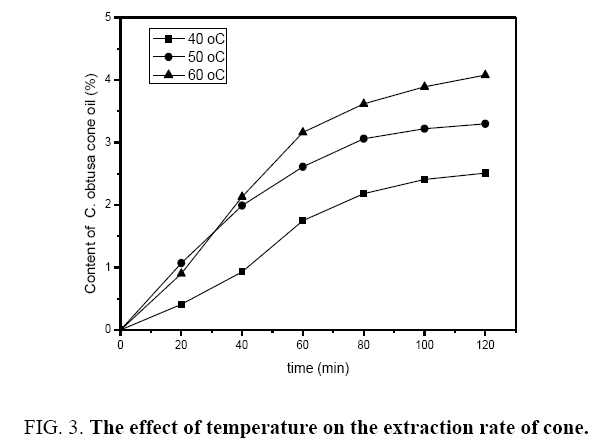

With cone, same experiments were made at different temperature 40°C, 50°C and 60°C. Results were monitored according to the time as shown in Table 4. With cone, different temperature resulted different yield of oil extraction. At 60°C, the yield was the highest as 4.08%. The time dependent changes of yield could be also used to determine the extraction rate as shown in Figure 3. With cone, the temperature dependency on extraction yield and rate was higher than other parts.

| Time (min) | Yield at different temperature (%) | ||

|---|---|---|---|

| 40°C | 50°C | 60°C | |

| 20 | 0.41 | 1.07 | 0.9 |

| 40 | 0.93 | 1.99 | 2.13 |

| 60 | 1.75 | 2.61 | 3.16 |

| 80 | 2.18 | 3.06 | 3.62 |

| 100 | 2.41 | 3.22 | 3.89 |

| 120 | 2.51 | 3.3 | 4.08 |

Table 4: The effect of temperature on supercritical CO2 extraction yield of cone.

Conclusion

Supercritical CO2 extractions were made with different parts of C. obtusa. Different part of C. obtusa resulted different extraction yields. The highest yield was obtained from leaves. The supercritical CO2 extraction of C. obtusa was influenced by temperature. Different temperature resulted different yield of oil extraction. When the temperature increased from 40°C to 50°C and 60°C, the yield increased. At 60°C, the yield was the highest. Among various parts of C. obtusa, the cone showed higher temperature dependency on extraction yield and rate was higher than other parts. Another different result by extraction was different colors. The color of each oil extracted was different. The oil color from leaves was deep green. The oil from wood was brown red. Oil colors from bark and cone were yellow and brown respectively.

Acknowledgements

This study was supported by a grant of the Korean Health Technology R&D Project, Ministry of Health and Welfare, Republic of Korea (Grant No.:HN14C0087).

References

- Q Li, M Kobayashi, Y Wakayama, et al. Effect of phytoncide from trees on human natural killer cell function. Int J ImmunopatholPharmacol. 2009;22:951-59.

- Abe T, Hisama M, Tanimoto S, et al. Antioxidant effects and antimicrobial activites of phytoncide. BiocontSci 2008:13:23-7.

- Ahn JY, Lee S, Kang H. Biological activities of essential oil from Chamaecyparis obtuse. J SocCosmet Scientists Korea. 2004:30:503-7.

- Yang JK, Hong SC, Kang MJ, et al. Efficient extraction methods and analysis of essential oil from softwood leaf. Proceedings of the Korean Society of Plant Biotechnology Conference. 2002:17:357-64.

- Moalem G, Tracey DJ. Immune and inflammatory mechanisms in neuropathic pain. Brain Res Rev. 2006:51 240-64.

- Weinberg JB. Nitric oxide synthase 2 and cyclooxygenase 2 interactions in inflammation. Immunol Res. 2000:22:319-42.

- Anti-inflammatory activity of essential oil extracted fromChamaecyparisobtusa (Sieb. etZucc.) wood kor. J Pharmacogn. 2017;48:18-24.

- Shin MK, Hong JH, Hur SS, et al. Extraction of β-carotene in co-solvent induced SFE process. Food EngProg 2002;6:301-7.

- Marimuthu P, Wu CL, Chang HT, et al. Antioxidant activity of the ethanolic extract from the bark of Chamaecyparisobtusa var. formosana. J Sci Food Agric. 2008;88:1400-5.

- Ju YW, Son MH, Lee JS, et al. Supercritical CO2 extraction of sesame oil with high content of Tocopherol. The Korean Society For Biotechnology And Bioengineering (KSBB Journal) 2005;20: 210-14.

- Cho SE. Anti-oxidative, anti-inflammatory and immunomodulatory effects of Chamaecyparisobtusa leaves extracts for atopic dermatitis. Department of Bioengineering Graduate-School of Konkuk University. 2012.

- Botelho JRS, Medeiros NG, Rodrigues AMC, et al. Production of black sesame (Seesamumindicum L.) seeds extract by supercritical fluid extraction: Isotherms of global yield and determination of total fatty acids. III IberoAmerican Conference on Supercritical Fluids, Cartagena de Indias (Colombia). 2013.

- Kim JW, Choi WS, Lee SS, et al. Comparative study on the composition of essential oil by supercritical carbon dioxide extraction and hydro-distillation from Chamaecyparisobtusaleaves. Journal of the Korean Wood Science and Technology. 2015;43:494-503.

- Doker O, Salgin U, Yildiz N, et al. Extraction of sesame seed oil using supercritical CO2 and mathematical modeling. J Food Eng. 2010:97:360-66.