Original Article

, Volume: 16( 1)Experimental Investigation of Heat Transfer Characteristics in a Circular Tube Fitted with Triangular-Cut Twisted Tape (TCTT) Inserts

- *Correspondence:

- Sivakumar K, Research Scholar, Department of Mechanical Engineering, Bharath University, Chennai, India, Tel: 044-2229 0742; E-mail: sivakssv@gmail.com

Received: January 12, 2018; Accepted: January 30, 2018; Published: February 03, 2018

Citation: Sivakumar K, Rajan K. Experimental Investigation of Heat Transfer Characteristics in a Circular Tube Fitted with Triangular-Cut Twisted Tape (TCTT) Inserts. Int J Chem Sci. 2018;16(1):244

Abstract

An experiment was conducted to investigate the friction factor characteristics and heat transfer characteristics of a concentric tube with triangular cut twisted tape (TCTT) insert with twist ratio Y is 5.4 and depth of triangular cut was 1.2 cm were studied for laminar flow. This investigation also to find the Nusselt number, heat transfer coefficient and Reynolds number. The heat transfer enhancement was caused with the flow of fluid between the plain twisted tapes and twisted tape with triangular cut (TCTT). The experimental value of plain tube and triangular cut twisted tape obtained from the experimental work and these two-statistical data were compared with the results. The results shows that the heat transfer rate enhancement of induced with plain and with the increase of Reynolds number, TCTT inserts was increases. The Reynolds numbers were varied in the range of 5710 to 18366. At analogous of Reynolds number with Nusselt numbers in the tube with triangular-cut twisted tape insert were enhanced by 1.1 to 1.3 times compared to that of plain twisted tape tube. The configuration of TCTT insert offered higher friction factor and heat transfer rate than the plain twisted inserts.

Keywords

Triangular-cut twisted; Heat transfer rate; Plain twisted; Twist ratio; Friction factor

Introduction

Heat exchangers have used for several industrial and engineering applications to improve the performance of heat exchanger devices for enhancement of heat transfer. A majority of heat exchangers used in chemical processing plants, air conditioning equipment, thermal power plants, etc. The heat transfer augmentation techniques are generally classified into three categories namely, Active techniques and Passive techniques and compared techniques. Salman et al. [1] have investigated in a circular tube fitted with Quadrant-cut twisted tape inserts by using CFD analysis of the heat transfer and friction factor characteristic. Al Amin et al. [2] investigating the heat transfer enhancement using a rotating twisted tape insert. Date and Saha [3] investigated in a tube fitted with regularly spaced twisted tape elements of the heat transfer. Salam et al. [4] discussed the heat transfer enhancement using twisted tape insert in a tube. Bodius et al. [5] have studied the heat transfer enhancement using rectangular-cut twisted tape insert in a tube. Pratik and Warkhedkar [6] were studied about the Heat Transfer Enhancement using Elliptical-Cut Twisted Tape Inserts in a Tube. Durga Prasad et al. [7] investigated the trapezoidal-cut twisted tape insert using Al2O3/water nanofluidT1, T2, T3, T4, to find the surface in a double pipe u-tube heat exchanger. Salman et al. [8] have discussed with V-cut twisted tape inserts of the numerical investigation of heat transfer and friction factor characteristic in a circular tube. Naga Sarada et al. [9] have analyzed the enhancement of heat transfer using twisted tape inserts varying width, were correlation are developed for friction factors and Nusselt number for a fully developed turbulent swirl flow. Chang et al [10] have predicting the pressure drop and heat transfer in tube with broken twisted tape inserts with varying twist ratio. Sivashanmugam [11] were discussed the experimental studies of laminar flow through a tube fitted on heat transfer and friction factor characteristic. Eiasma-ard et al. [12] discussed in a circular tube fitted twisted tape insert the convective heat transfer.

Murugesan et al. [13] have analyses the turbulent flow heat transfer in tube fitted with square cut twisted tape. Sarma et al. [14] approach the heat transfer analysis in tube with twisted tape inserts. Monheit et al. [15] studied about the experimental investigation of the twisted tape inserts. Promvonge et al. [16] has analyses the heat transfer behavior on twisted tape inserts. Duplesis et al. [17] analyses using twisted tape inserts, the experimental studies on heat transfer augmentation techniques. Salman et al. [18] were studied about the numerical investigation in a circular tube fitted with V cut twisted tape inserts of heat transfer and friction factor characteristics. Saha et al. [19] investigated of laminar flow in a tube fitted with regularly spaced twisted tape elements the heat transfer. Gnielinski et al. [20] analyses the new equations for heat and mass transfer in turbulent pipe flow and channel flow. The twisted tape inserts were discussed in many literature surveys of the heat transfer and friction factor characteristics [21-30].

Experimental

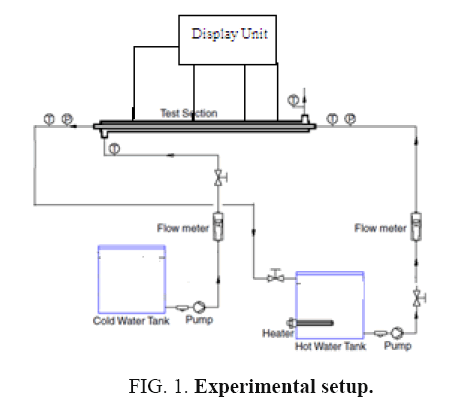

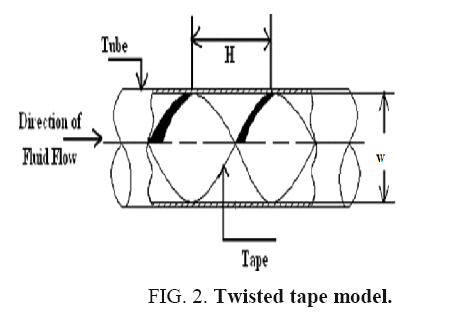

The configuration of geometry of the tube with a thickness (t) 0.075 cm, length (L) 220 cm is used for experimental investigation. In a double pipe heat exchanger as the heat transfer test section to minimize heat loss to the surrounding this is insulated. It consists of two concentric tubes in which hot water flows through the inner tube and cold water flows outer tube in flow through annulus. The outer tube is made of a cast iron having inside and outside diameters of 28 mm and 32 mm respectively. The inner tube made of an aluminum having inside and outside diameters of 20 mm and 18 mm respectively. Water is supplied to the pipe from the water loop, an electrical heater controlled by adjusting the voltage, a stirrer and flow meter is placed in the path of the water supply.

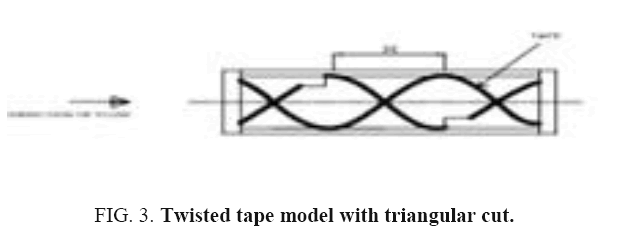

The temperature sensors were used to measure the outlet temperature of hot and cold fluid and Four thermocouples were used T1, T2, T3, T4, to find the surface temperature of heat exchanger and data was recorded using data acquisition unit. The cold water is supplied from storage tank into the outer tube and hot water is supplied in the inner tube. The flow meter and pressure gauge were used to measure the mass flow rate of hot fluid and cold fluid flow. The volumetric flow rates of the hot and cold fluid were adjusted by control valves, situated before the inlet ports and experimental reading was taken with different flow rates for obtained the different experimental data. The experimental data occurred for plain twisted tape and triangular-cut twisted tape (TCT). The temperature of the inlet and outlet of hot and Coldwater data’s were gathered. The experimental configuration illustrated in Figure 1-3.

Figure 3: Twisted tape model with triangular cut.

The experimental set-up consists of:

1. Electrical heater

2. Pressure gauge

3. Temperature indicator

4. Flow meter

5. Display unit

Double pipe heat exchanger with twisted tape.

Heat transfer rate was calculated

Q=m Cp (Tout–Tin) ............. (1)

Heat transfer coefficient can be calculated

h=q/(Tw –Tb) ............. (2)

Reynolds number was calculated

Re=UD/? ............. (3)

Nusselt number can be obtained

Nu=h D/K ............. (4)

Results and Discussion

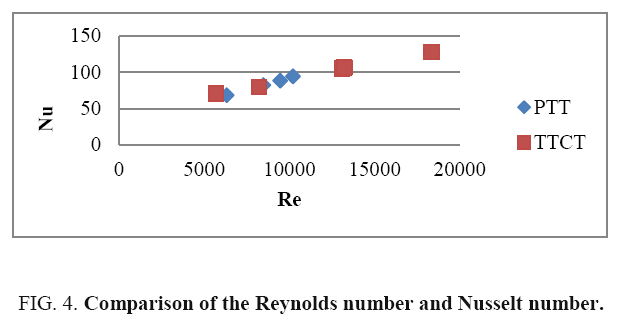

The measured data of friction factor and heat transfer for the plain twisted tape tube were collected and then these data were taken to compare the experimental set up of triangular-cut twisted tape inserts and over the range of Reynolds number 5710 to 18366 with measurement techniques. Figure 4 shows the comparison of Reynolds number and Nusselt number of experimental data of plain twisted tape (PTT) and triangular-cut twisted tape (TCTT). It is seen that, the Nusselt number with triangular-cut twisted tape inserts were gives higher values than the plain twisted tape inserts. With increases of Reynolds number the Nusselt number also increased. From the observation, the plain twisted tape Nusselt number increases from 68 to 107, but the TCTT Nusselt number increases from 70 to 128.

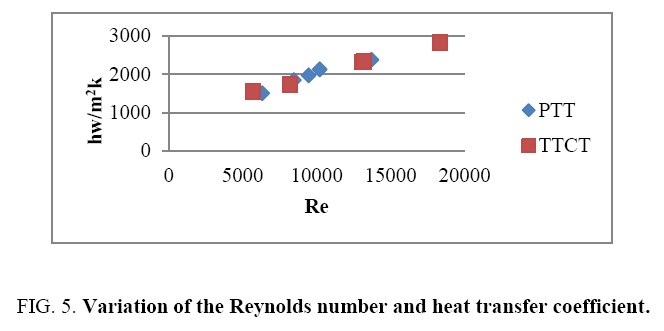

Errors were found to be in the range of +6% to +8%, At the comparable of Re and Nu with TCTT inserts were improved from 1.02 to 1.19 times compared with the plain twisted tape inserts (PTT). Figure 5 shows the variation of Reynolds number and heat transfer coefficient, at analogous of TCTT heat transfer coefficient increased with increases of Reynolds number and gives higher values than the PTT insert. Because of swirl flow generated by twisted tape was responsible the thermal boundary layer and increased mixing between the core and tube wall for thinning flows. The value of heat transfer coefficient for TCTT increased by 1.03 to 1.19 times enhanced than the PTT.

Effect of cut depth and twist ratio on heat transfer and friction factor

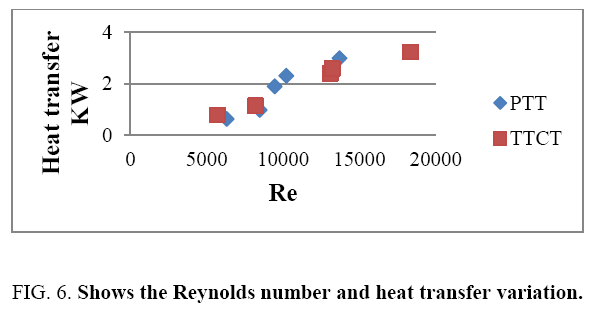

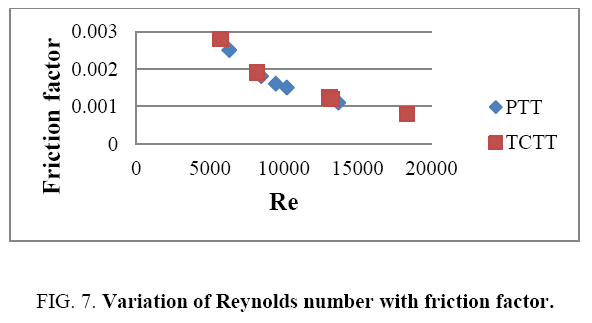

The experimental data of the friction factor and heat transfer of PTT and TCTT and these variation with a Reynolds number of twisted tape inserts with twist ratio y=5.4 is shown in Figure 6 and 7. It indicates that the heat transfer rate of PTT is higher than the TCTT insert. It is obvious that the narrow twist ratio yielded with TCTT offered higher values of heat transfer than the plain twisted tape inserts. For the given Reynolds number, the Nusselt number and heat transfer rate were enhanced with TCTT insert at comparable of PTT. The TCTT heat transfer rate is enhanced by 1.2 to 1.8 times with comparable than the PTT. The depth of cut was taken as by 0.5 cm and cut twisted tape was responsible for the tangential contact between secondary flow and the wall surface of the tube, additional disturbance which increased. This made the heat transfer rate is increases through the twisted flow and twisted cut tape flow. The errors to be found to be in the range of +8%. Figure 7 shows the comparison of Reynolds number and friction factor. The Reynolds number increased with decreasing the friction factor, because of the twisted tape inserts caused swirling flow in the tube; it is mainly due combined effect of swirl flow and turbulence generated by the alternate’s cuts in the twisted tape. It was observed that the friction factor was decreased by 1.12 to 0.72 times than the Plain twisted tape inserts (PTT).

Conclusion

An experimental investigation carried out for plain twisted tape and triangular twisted tape for measuring heat transfer rate, friction factor, Reynolds number and Nusselt number. The values of the heat transfer coefficient, Nusselt number and heat transfer rate for the tube with triangular-cut twisted tape were considerably higher than the values of plain twisted tape inserts. The experimental heat transfer rate of TCTT values were found to be 21% to 24% enhanced than the PTT. The results show the TCTT offered more heat transfer than the plain twisted tape inserts. The heat transfer enhancement of experimental record was validating with TCTT and PTT: and the results obtained for additional disturbance which increased the tangential contact between secondary flow and wall surface. The friction factor reduced with increase of Reynolds number, these reductions caused due to swirl flow taken between the cut depth and twist in tape. The Nusselt number was increased with increases of Reynolds number. The experimental values of Nusselt number was increased with 1.02 to 1.19 times. From the experimental results of the plain twisted tape and triangular cut twisted tape, as the heat transfer rate increases by selecting optimum Reynolds number and twisted ratios. The smaller twist ratio can be used for the operation of the twisted tape, whenever higher heat transfer rate is required. The lower twist ratio enhances the heat transfer due to increases in transverse fluid motion.

References

- Salman SD, KadhumAAH,TakriffMS, et al. CFD analysis of heat transfer and friction factor characteristics in a circular tube fitted with quadrant cut twisted tape inserts. Mathematical Problems in Engineering.HindawiPublishing Corporation; 2013.

- Amin A,Mohamud Z, IslamNB,et al. Proceedings of 4thGlobal Engineering, Science and Technology Conference27-28 December, BIAM Foundation, Dhaka, Bangladesh.

- Date AW,Saha SK. Numerical prediction of laminar flow and heat transfer in a tube fitted with regularly spaced twisted tape elements. Int JFluid Flow. 1990;11:346-54.

- Salam B, Biswas S,Bhuiya MMK. Heat transfer enhancement in a tube using twisted tape insert.Proceedings ofthe 13th Asian Congress of Fluid Mechanics. 2010;pp:835-8.

- Bodius Salam B, BiswasS,Saha S, et al. Heat transfer Enhancementin a tube usingrectangular-cut twisted tape insert. International Conference on Thermal Engineering5th BSME Science Direct 2013;56:96-103.

- Ganorkar PP,WarkhedkarRM. Heat transfer enhancement in a tube using elliptical-cut twisted tape inserts. SSRG Int J MechEng (SSRG-IJME). 2015;2:5.

- Durga Prasad PV, DeepakK.Investigation of trapezoidal-cut twisted tape insert in a double pipe U-tube heat exchanger using Al2O3/waternanofluid.2nd International Conference on Nanomaterials and Technologies (CNT) Science Direct. 2015;10:50-63.

- SalmanSD, KadhumAAH, TakriffMS, et al. Numerical investigation of heat transfer and friction factor characteristics in a circular tube fitted with V-cut twisted tape inserts. Mathematical Problems in Engineering.HindawiPublishing Corporation. 2013;pp:1.

- Naga Sarada S, Rama Raju AVS, Kalyani RadhaK, et al. Enhancement of heat transfer using varying width twisted tape inserts. Int J EngSci Technol. 2015;6:107-18.

- Chang SW, Yang TL,Liou JS. Heat transfer and pressure drop in tube with broken twisted tape insert. ExpTher Fluid Sci. 2007;2:489.

- SivashanmugamP,NagarajanPK. Studies on heat transfer and friction factor characteristics of laminar flow through a circular tube fitted with right and left helical screw-tape inserts.ExpTherm Fluid Sci. 2007;32:192-7.

- Eiasma-ard S,Thianpong C,Eiasma-ardP. Convective heat transfer in a circular tube fitted with short length twisted tape inserts. IntComm of Heat and Mass Transfer. 2006;33:1225-33.

- Murugesan P, MayilsamyK, SureshS.Turbulent heat transfer and pressure drop in tube in tube fitted with square cut twisted tape. Fluid Flow and Transport Phenomena. 2010;14:609-17.

- SarmaPK, KishorePS, RaoVD, et al. A Combined approach to predict friction coefficients and convective heat transfer characteristic in a tube with twisted tape inserts for wide range of Re and Pr.Int J Therm Sci. 2005;44:393-8.

- MonheitM. Experimental evaluation of the convective characteristic of tubes with twisted tape insert.Advances in Enhanced Heat Transfer. ASME, New York. 1987;11-8.

- Promvonge P,Eiasma-ardS. Heat transfer behaviors in a tube with combined conical-ring and twisted tape insert. IntComm in Heat and Mass Transfer. 2007:34:849-59.

- Duplesis JP,Kroeger DG. Numerical prediction of laminar flow with heat transfer in tube with twisted tape insert.Proceeding of the International Conference on Numerical methods in Laminar and Turbulent flow. 1983;pp:775-85.

- SalmanSD, KadhumAAH, TakriffMS, et al. Numericalinvestigation ofheat transfer and friction factor characteristics in a circular tube fitted with V-cut twisted tape inserts. The Scientific World J. 2013;8.

- SahaG, GaitondeUN, DateAW. Heat transfer and pressure drop characteristic of laminar flow in a circular tube fitted with twisted tape element.Exp of Therm Fluid Sci. 1989;2:310-22.

- Gnielinski V.New equations for heat transfer and mass transfer in turbulent pipe flow and channel flow. IntChem Eng. 1976;16:359-68.

- HejaziV, Akhavan-BehabadiMAM,AfshariA. Experimental investigation of twisted tape inserts performance on condensation heat transfer enhancement and pressure drop. IntComm in Heat and Mass Transfer. 2010;37:1376-87.

- SyamSundarL, SharmaKV.Turbulent heat transfer and friction factor of Al2O3 Nanofluid in circular tube with twisted tape inserts. Int J Heat and Mass Transf. 2010;53:1409-16.

- Eiamsa-ard S, NivesrangsanP, ChokphoemphunS, et al. Influence of combined non-uniform wire coil and twisted tape inserts on thermal performance characteristic.IntComm Heat Trans. 2010;37:850-6.

- Sarma PK, Subramanyam T, Kishore PS, et al. Laminar convective heat transfer with twisted tape inserts in a tube.Int J Therm Sci. 2003;42:821-8.

- Jaisankar S, Radhakrishnan TK, Sheeba KN, et al. Experimental studies on heat transfer and friction factor characteristics of thermosyphon solar water heater system fitted with left-right twisted tapes. International JApp Eng Res. 2008;3(8):1091-103.

- Al-Fahed S,Chakroun W. Effect of tube-tape clearance on heat transfer for fully developed turbulent flow in a horizontal isothermal tube. Int J Heat Fluid Flow. 17:2:173-8.

- Al-Fahed S,Chamra L M, Chatroun W. Pressure drop and heat transfer comparison for both micro fin tube and twisted tape inserts in laminar flow. ExpTherm Fluid Sci. 1998;18:4:323-33.

- Akhavan-Behabadi MA, Jamali-Asthiani M. Effect of twisted tape insert on heat transfer and pressure drop in horizontal evaporators for the flow of R-134. Int J Ref. 2009;32(5):922-30.

- Sivashanmugam P, Suresh S. Experimental studies on heat transfer and friction factor characteristics of turbulent flow through a circular tube fitted with tape inserts. ChemEngProcess. 2007:46:1292-8.

- ManglikaRM,BerglesAE. Swril flow heat transfer and pressure drop with twisted tape inserts. Advances in Heat Transfer. 2003;36:183-266.