Research

, Volume: 21( 1)Design of Fermenter and Fluidized Bed Bioreactor

- *Correspondence:

- Ramesh Chandragiri

Department of Biotechnology, Jawaharlal Nehru Technological University, Hyderabad, Telangana, India

Tel: 9642170918

E-mail: rameshchandragiri0@gmail.com

Received: November 12, 2022, Manuscript No. TSIJCS-22-79624; Editor assigned: November 15, 2022, PreQC No. TSIJCS-22-79624 (PQ); Reviewed: November 29, 2022, QC No. TSIJCS-22-79624; Revised: February 24, 2023, Manuscript No. TSIJCS-22-79624 (R); Published: March 02, 2023, DOI: 10.37532/0972-768X.2023.21(1).430

Citation: Chandragiri R, Chakravarthy N. Design of Fermenter and Fluidized Bed Bioreactor. Int J Chem Sci. 2023;21(1):430.

Abstract

The influences of ambient conditions and treated has to done by cell level perspective of mass transfer and heat transfer by microbial system. The effects considered are (i) consumption of substrates, (ii) output of products, (iii) production of heat and (iv) aggregation and direct influenced by microbial environment conditions. The drawback of environmental control is treated for the case of a stirred tank fermenter and the control parameters considered are system geometry, aeration rate, intensity of agitation, temperature, pressure, nutrient supply, pH and other parameters involving, dilution rate in continuous systems and foaming. Design of fermenters and automation of fermentations does not provide a detailed insight. Fluidized bed bioreactors as well as development of knowhow for production of a variety of food enzymes (typically used on small food products like peas, shrimp or sliced vegetables,) have led to the commercial exploitation of the technology by industry.

Keywords

Components of fermenter; Ideal fermenter; Fluidized bed bioreactor; Consumption of substrates; Foaming

Introduction

Biotechnology is more than 8000 years of human experience using living organisms and the process of fermentation to make products such as bread, cheese, beer and wine. Today biotechnology is applied to manufacturing processes used in health care, food and agriculture, industrial and environmental cleanup, among other applications. The design of fermentation equipment has evolved in a largely empirical manner [1].

The earliest fermentations required only basic standards of hygiene, either because of the nature of the substrate or because the vigor of the desired organism exceeded that of potential competitors or because the products of fermentation were restrictions or because the expected shelf life of the product was short. Even with these products the transition from domestic art to commercial practice required improved standards to increase shelf life and to maintain acceptably consistent standards of product quality, but equipment and process control remained essentially simple. Some sophistication occurred with the development of pure culture techniques in beer making, but the first really fastidious fermentation, the manufacture of acetone and butanol, was initiated on a large scale less than sixty years ago [2-4].

In this system the maintenance of a strictly anaerobic environment was essential. This provided protection against a wide range of contaminants requiring atmospheric oxygen and the principal hazard was contamination by bacteriophage. The next major development was the adaptation of submerged culture techniques for the production of penicillin, rapidly followed by processes for other antibiotics, vitamins, amino acids and the conversion of steroids. These processes have been developed over the past thirty years or so and have attracted the combined attention of microbiologists, biochemists and engineers to resolve a variety of problems in order to improve both yields and process efficiency. More recently, a good deal of attention has been devoted to problems associated with the replacement of batch processes by continuous processes, and the utilization of gaseous and liquid hydrocarbons as substrates, instead of the traditional carbohydrates [5]. The latter processes, in particular, have stimulated investigations into the use of fermenter configurations other than the agitated cylindrical vessel which has been almost universally adopted for aerobic microbial processes and for some anaerobic processes. Among the new configurations, two in particular the air lift and the towers have been exploited commercially and have attracted the attention of research workers.

Materials and Methods

Design of fermenter

Components of fermenter:

• Basic component includes drive motor, heaters, pump, etc.

• Vessels and accessories.

• Peripheral equipment (reagent bottles).

• Instrumentation and sensors.

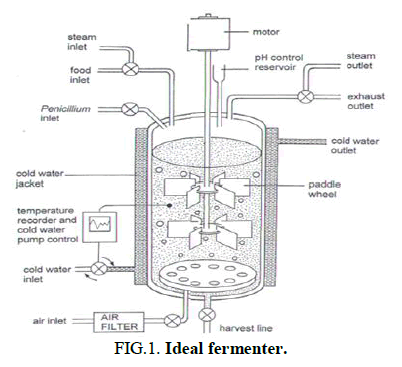

Various components of an ideal fermenter for batch process are (Figure 1):

Results and Discussion

Glass vessel (borosilicate glass)

Type 1: Glass vessel round or flat bottom with top plate. It can be sterilized by autoclaving and the largest diameter is 60 cm.

Type 2: Glass vessel flat bottom with top and bottom stainless steel plate. This type is used in in situ sterilization process and the largest diameter 30 cm.

Stainless steel

Stainless steel is used as vessel construction material with the following modifications,

• >4% chromium (at least 10%-13%) may be added.

• Film of thin hydrous oxide non-porous, continuous, self-healing, corrosion resistance.

• Inclusion of nickel improves engineering.

• Presence of molybdenum resistance to halogen salts, brine, sea water.

• Tungsten, silicone improves resistance.

Thickness of vessel should be increased with scale. Side plates have lower thickness than top and bottom plates. Top and bottom plate are hemispherical to withstand pressures.

Sealing: Sealing between top plate and vessel is an important criterion to maintain airtight condition, aseptic and containment. This sealing ensures tight joint in spite of expansion of vessel material during fermentation.

Baffles: Baffles are metal strips that prevent vortex formation around the walls of the vessel. This movement minimizes microbial growth on baffles and fermentation walls. If needed cooling coils may be attached to baffles.

Aeration system (sparger): Sparger is a device for introducing air into fermenter. Aeration provides sufficient oxygen for organism in the fermenter. Agitation is not required when aeration provides enough agitation which is the case air lift fermenter. But this is possible with only for medium with low viscosity and low total solids.

Exit gas cooler: Similar to liebig condenser, condenses the moisture from the exhaust gas in the fermenter. This removes as much moisture as possible from the gas leaving the fermenter and prevents excess fluid loss.

Agitation: Agitation provides uniform suspension of cells in homogenous nutrient medium. This agitation provides bulk fluid and gas phase mixing, air dispersion, facilitates oxygen transfer and heat transfer and uniform environment throughout the vessel.

Stirrer glands and bearings: The entry point of stirrer into fermenter may be from top to bottom or sides. Mostly used from bottom so that that leaves more space for entry ports on top. There are four types of stirrer glands and bearings are stuffing box, mechanical seal, magnetic drives (some animal cell cultures) and simple bush seals [6].

Check valves: Valves used to prevent accidental reversal flow of liquid or gas due to break down. There are three types swing check, lift check, combined stop and check.

Pressure control valves

These types of valves are used for two purposes.

• Pressure reduction.

• Pressure retaining.

Safety valve: There are types of safety valve by which the increase in pressure is released. They are:

• A spindle lifted from its seating against the pressure releases pressure.

• Bursting/rupturing of discs to release pressure.

In case of releasing the gas, the escaping gas must be treated before release.

Steam traps: This steam trap is important to remove any steam condensate. There are two components viz. valve and seat assembly and open/close device. The operation of the component is based on:

Density of fluid: A float (ball/bucket) float in water, sink in steam. When it floats it closes and when it sinks it opens the valve.

Temperature of fluid: It has water/alcohol mixture which senses the change in temperature. This mixture expands in hot steam and closes the valve. When it contracts in cool water opens the valve.

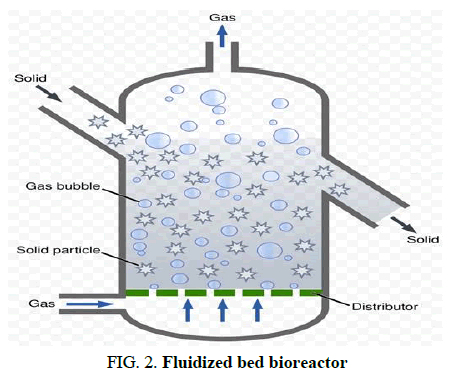

Kinetic effect of fluid in motion: If a low density steam is flowing it will be high velocity. The conversion of pressure energy into kinetic energy control the opening and closing (Figure 2).

Fluidized bed bioreactor

Fluidized Bed Bioreactors (FBB) has received increased attention in the recent years due to their advantages over other types of reactors. Most of the FBBs developed for biological systems involving cells as biocatalysts are three phase systems (solid, liquid and gas). The fundamentals of three phase fluidization phenomena have been comprehensively covered in chemical engineering literature. The FBBs are generally operated in co-current up flow with liquid as continuous phase and other more unusual configurations like the inverse three phase fluidized bed or gas solid fluidized bed are not of much importance. Usually fluidization is obtained either by external liquid re circulation or by gas fed to the reactor. In the case of immobilized enzymes the usual situation is of two phase systems involving solid and liquid but the use of aerobic biocatalyst necessitate introduction of gas (air) as the third phase. A differentiation between the three phase fluidized bed and the airlift bioreactor would be made on the basis that the latter have a physical internal arrangement (draft tube), which provides aerating and non-aerating zones. The circulatory motion of the liquid is induced due to the draft tube [7].

Mass transfer

The transfer of mass within the system is fundamental to the whole operation. More or less uniform distribution of substrate and product molecules in the bulk of the fluid and transfer between the bulk of the fluid and the microbial cells.

Largely governed by the forced convection and turbulence produced by agitation and the flow of gas, whereas transfer between the bulk and cells is determined by diffusional forces [8].

When supplied in a stream of air, as is usually the case, the equilibrium concentration in fermentation media is only of the order of five to ten times the limiting concentration, even in the absence of microbial activity. In an actively respiring culture this margin is further reduced.

Heat transfer

Heat is generated in submerged microbial systems, partly by the metabolic activity of the organisms and partly as a result of the mechanical work performed by the agitator and by the gas bubbles as they expand in passing from the sparger to the head space above the culture. In mechanically agitated systems the work performed by gas expansion is usually a small proportion of the total.

In one important respect the process of heat transfer differs from that of mass transfer. Whereas mass transfer takes place throughout the whole of the dispersion, the interchange of heat with the surroundings takes place at well defined and fixed boundaries.

Conclusion

Biological activity depends basically on the microenvironment surrounding each cell. In practice, control of the microenvironment must be exercised rather indirectly through control of the overall conditions in the apparatus in which the process is conducted.

Fuller knowledge of physical conditions in microbial cultures and of their effects on biological activity will help to resolve these issues and to improve both equipment and process design.

There seems no reason to believe that the sparged, agitated, baffled vessel will be displaced from its position of preeminence, but better characterization may lead to better exploitation and to the identification on rational grounds of situations in which radically different types of contacting equipment may be justified.

Fluidized bed bioreactors have huge potential in a wide range of bioprocesses, due to their essential advantages and also to the possibilities that they offer to the engineers to change their design in order to enhance their performance. However, they are also more complex and need to be well characterized in order to obtain a reliable as comparatively as air lift fermenter, batch st irred fermenter and also packed bed reactor and stable performance.

Three phase hydrodynamics and a good knowledge of the immobilized biocatalyst behavior are the key problem to attain successfully such a characterization and also to develop useful models for design, operation, control and scale up of fluidized bed bioreactors.

References

- Stanbury P, Whitaker A, Hall SJ. Principles of fermentation technology. 3rd edition, Pergamom Press, London, United Kingdom, 2016.

- Loucaides R, McManamey WJ. Mass transfer into simulated fermentation media. Chem Eng Sci. 1973;28(12):2165-2178.

[Crossref]

- Stanvury PF, Whitaker A. Principles of fermentation technology. 2nd Edition, Pergamom Press, London, United Kingdom, 1995.

- Yoshida F, Yamane Y, Yagi H. Mechanism of uptake of liquid hydrocarbons by microorganisms. Bioethanol Bioeng. 1971;13(2):215-228.

[Crossref] [Google Scholar] [PubMed]

- Bailey J, Ollis D. Biochemical engineering fundamentals. 2nd edition, McGraw Hill Book Compa, United States, 2017.

- Andrews GF, Przezdziecki J. Design of fluidized bed fermentors. Bioethanol Bioeng. 1986;28(6):802-810.

[Crossref] [Google Scholar] [PubMed]

- Godia F, Sola C. Fluidized bed bioreactors. Biotechnol Prog. 1995;11(5):479-497.

- Reiter M, Bluml G, Gaida T, et al. Modular integrated fluidized bed bioreactor technology. Biotechnology. 1991;9(11):1100-1102.

[Crossref] [Google Scholar] [PubMed]