Original Article

, Volume: 6( 1)An Experimental Insight into Thermoacoustic Smoldering

- *Correspondence:

- Vinayak M , Assistant Professor, Department of Aerospace Engineering, SRM University, Chennai, Tamil Nadu, India, Tel: 09840599069; E-mail: vinn99@gmail.com

Received: March 16, 2016; Accepted: April 17, 2017; Published: April 20, 2017

Citation: Pratik T, Vikram R, Vinayak M. An Experimental Insight into Thermoacoustic Smoldering. J Space Explor. 2017;6(1):119.

Abstract

Most of the combustion processes are accompanied by sound which significantly affects the progression. The work attempts to gain physical insight into the acoustic-thermal energy interaction and related implications on smoldering combustion. Thorough experiments were carried on incense stick with systematic variation of surface orientation and distance between sound source and fuel for a fixed frequency sound. The acoustic effect was observed and evaluated with variation in fuel regression rates under diverse conditions. Spreading process on a thin solid fuel under conditions of varying surface orientation and constant exposure to sound varies significantly. The change due to acoustics follow similar trend as without with upward and downward spread undergoing maximum effect. The resultant heterogeneous heat transfer owing to change in localized temperature and velocity fields is explored. The thermoacoustics interaction significantly increase the forward heat transfer with varying source separation distance. The maximum acoustic effect occurs at an intermediate sound source location whereas, the minimum effect was evaluated to occur with nearby placement of sound source. Two distinct zones are established based on external sound source location indicating no effect) and drastic rise for upward and downward spread.

Keywords

Acoustics; External sound source; Forward heat transfer; Regression rate; Smoldering; Surface orientation

Introduction

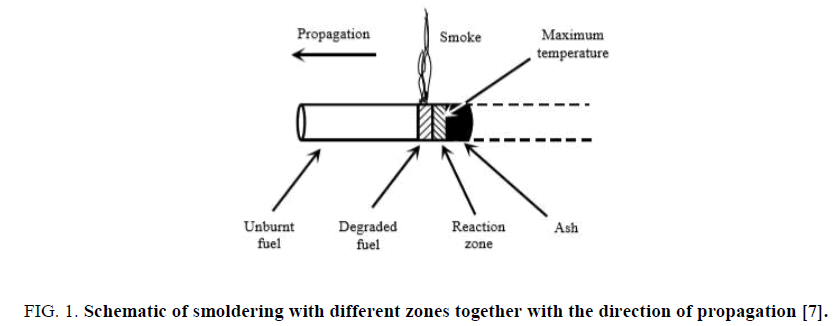

Smoldering fires are detected as the most serious hazard to functional engineering systems on earth and in space operations. The phenomenon embodies twofold behavior of practical utility and stern hazards with issues yet to be thoroughly addressed. Unlike flaming, smoldering characterizes a slow low-temperature combustion which manifests as a potential source of substantial fire hazards generating momentous loss of nature, resources, economy, and fire deaths. Smoldering initiates almost all the fires including compartment fires, forest fires, dust explosions and fire safety concern aboard space facilities as the absence of gravity is known to promote smoldering propagation. Uniqueness of smoldering reflects in, easy initiation by weak heat sources, high conversion of fuel to toxic products (particularly CO), can shortly cause transition to flaming combustion and difficult to detect and extinguish. The interest in smoldering combustion is driven by the need to have enhanced understanding of the phenomenon. Thermochemically, physics of smoldering states, self-sustained combustion owed to heat generated by an exothermic reaction between oxygen and a solid fuel. Materials are known to thermally decompose on exposure to heat. Combustion comprises of solid fuel degradation in presence of oxygen whereas, in absence of oxygen leads to pyrolysis which is an endothermic reaction. The propagation of smoldering ignition front is well known to develop in three different zones viz., degradation, smoldering reaction and ash (Figure. 1). As a process, all three zones contribute proportionally in propagation of ignition front. The maximum temperature occurs in reaction zone due to the smoldering combustion of the fuel. The solid fuel is degraded and post combustion consists of form ash which prevents heat loss. A part of thermal energy released in combustion is transferred to the unburnt fuel known as Forward heat transfer. This heat transfer preheats the unburnt fuel and maintains smoldering front propagation.

Figure 1: Schematic of smoldering with different zones together with the direction of propagation [7].

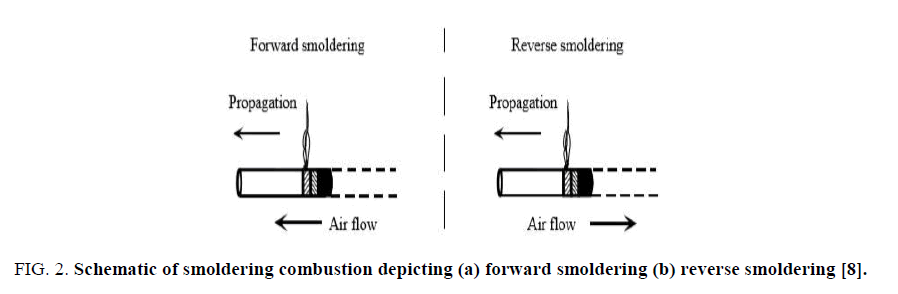

Smoldering combustion is broadly studied and defined according to the direction in which the smolder reaction propagates relative to the oxidizer flow (Figure. 2), classified as: Forward smoldering where the air moves in the same direction as the smoldering front and Reverse smoldering where the air moves in the opposite direction of the smoldering front.

Figure 2: Schematic of smoldering combustion depicting (a) forward smoldering (b) reverse smoldering [8].

In a reverse smoldering, the oxygen reaches the reaction zone by moving through the unburnt fuel and the degradation zone whereas, heat is transported from the burning to the unburnt region. The heat transfer is primarily by conduction and radiation and the opposed air movement prevents heat transfer by convection. In a forward smoldering fire, the air moves in the same direction as the smoldering reaction zone. As a result, forward heat transfer is assisted and thus oxidation of the fuel continues until all the fuel is consumed. Thus, enhanced pre-heating of the unburnt fuel causes the ignition front to accelerate.

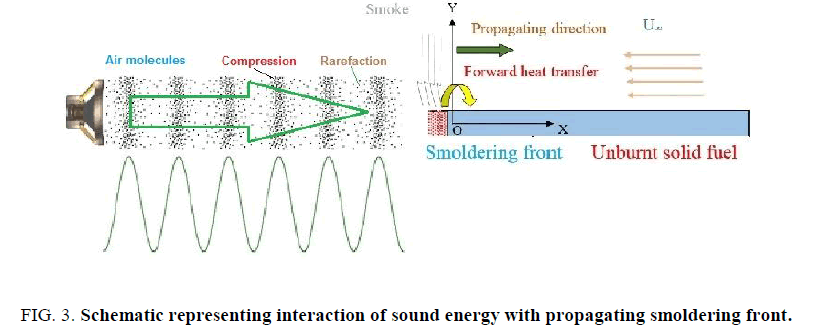

An important aspect in attention is the existence of sound in combustion processes. The occurrence or presence of sound affects the ignition and thus propagation process. Sound epitomizes energy with periodic variation of pressure, density and temperature in terms of pressure wave (periodic air displacement) involving periodic molecular compression and expansion termed as Infrasound (20 Hz to 200 Hz) and Ultrasound (20 kHz to 100 kHz). For smoldering process, acoustics exposure is likely to result in periodic changes in the speed of chemical processes thus heterogenous heat and mass transfer with reflected in the altered propagation rates (Figure. 3). In due interaction, if more heat is released during the half period of high pressure, energy will be transferred from the combustion to the sound and vice versa.

Figure 3: Schematic representing interaction of sound energy with propagating smoldering front.

Research efforts have sprawled over a century with Semenov [1] highlighting the chemical Kinetics and chemical reactions. Significant smoldering combustion contributions are documented with Palmer [2], Browne [3] Bowes et al., [4], followed by stepwise advancement and development in understanding of the smoldering combustion reported in reviews like Kinbara et al., [5], Moussa et al., [6], Ohlemiller [7-12], Beever [13], Jones et. al., [14], Leach et. al., [15], Babrauskas [16], Rein [17,18], Hagen [19] up to the end of the century. The scientific works on inter energy interactions have been stretched in the last decade with appreciable advancements in thermoacoustics on the flame sound interaction. Chiu et al. [6] analyzed the turbulent combustion of premixed fuel and liquid fuel droplets and a unified theory of noise generation and amplification was developed. The investigation focused on the far field noise features and the mechanism of sound generation, dispersion, and transmission in the vicinity of an open flame. The acoustic intensity generated by a turbulent premixed flame was found to be a function of the aero thermochemical parameters and the flame structural factor. Noise amplification by acoustic instability contributed significantly to the combustion noise in high performance ducted spray combustors. Rein et al. [20] developed a one-dimensional computational model of smoldering combustion to predict the experimental observations in both reverse and forward propagation. The chemistry was modelled with a 5-step mechanism, so the model was able to predict qualitatively and quantitatively the smoldering behavior replicating the most important features of the process. Kampen [21] developed an efficient numerical algorithms to check combustion systems for their sensitivity to thermoacoustic instabilities. The work was based on the modern industrial gas turbine designs, for so-called thermo-acoustic instabilities, which arise from the interaction of heat and sound. The work highlighted, the flame transfer function representing dynamic relationship between a fluctuation in the inlet conditions of a flame and its acoustic response. The turbulent fluctuations in the flame was noted to act as a sound source, producing a sound field in the combustor and in the burner, upstream of the flame causing inlet properties of the flame to fluctuate, resulting in an acoustic response of the flame.

Rein [22] provided a synopsis of smouldering combustion complications in diverse disciplines. More emphasis was laid on the fact that the existing smoldering acquaintance cannot provide good understanding and that there is a need to conjunct more experimental and theoretical studies for improved understanding especially on the issues of ignition, extinction and the transition to flaming. Krivokorytov et. al. [23] assessed acoustic oscillations influence on the characteristics of diffusion flame (hydrocarbons combustion). The stipulation of nitrogen oxides concentration in the combustion products on the acoustic signal frequency was evaluated in view of the ecological safety aspect. Dowling and Mahmoudi [24] addressed entailing issue of confinement of combustion noise. They stated the general characteristics of direct and indirect noise. Tiwari et al. [25] detailed the expression for effect of controlling parameter surface orientation on regression rates for reverse and forward smoldering modes. Unlike conventional studies, result highlighted the maximum forward heat transfer enhancement at 45° for reverse and at 270° for forward smoldering modes. The study detailed investigation of an external heat source effect on the smoldering process. The work established a reconnection that similar to the flame, smoldering exhibits sensitiveness to an external energy source presence in near vicinity. Dowling [26] investigated the interaction between vortices, sound and combustion leading to self-excited oscillations of large amplitudes that invite structural damage. It was noted that, any small unsteadiness in the rate of combustion is a source of sound, generating pressure and velocity fluctuations. However, the velocity fluctuations perturb the flame, thereby altering the instantaneous rate of heat release. Instability was accounted possible because while acoustic waves perturb the combustion, the unsteady combustion generates yet more sound [27].

Smoldering fires diversity have associated several aspects not understood by the fire safety community viz., smoldering decomposition under varying conditions and influences. This has necessitated research efforts motivated by the need to have better combustion and improved fire safety by understanding of the governing mechanisms under diverse conditions. One of the fire inhibition method is through use of an external influence to eliminate spread. A spreading flame interaction with an external sound source have been comprehensively explored however, smoldering spread response to an external sound is an aspect yet to be investigated thoroughly. Acoustics is likely to alter the localized field around ignition front thus affecting pyrolysis of fuel resulting in reformed smoldering spreading rates. The extent of change is very likely to vary with the key controlling parameters viz., sound frequency, surface orientation, and source distance. The increase or decrease of regression rate can have significant effects and applications in engineering background. Present work, experimentally explores the implications of acoustic effects on smoldering spread in view of prevention and efficient utilization. The specific objectives of the study are:

• To study acoustic effects on the smoldering regression rates.

• To examine the effect of governing parameters.

Experimental Setup and Solution Methodology

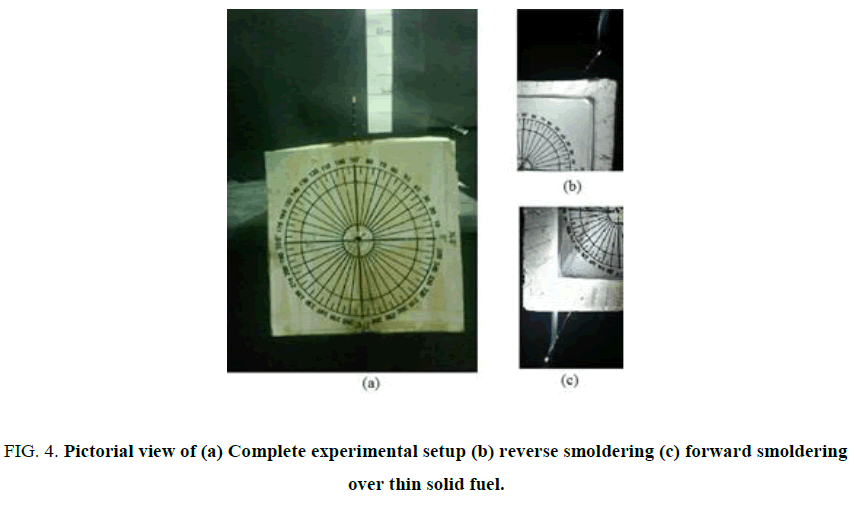

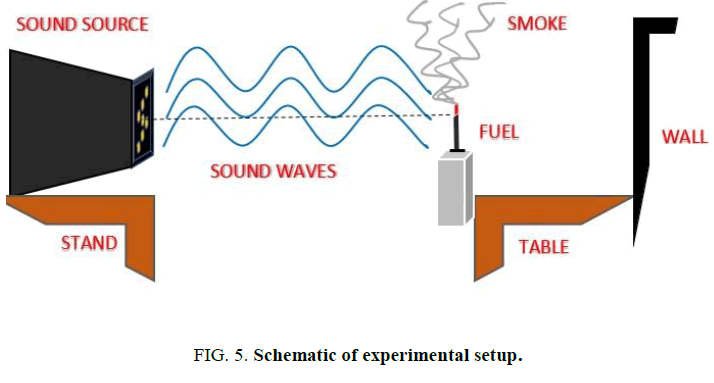

An experimental setup was upraised for the present study (Figure. 4) comprising of a hard thermocol with protractor fixed on it and firmly supported in front of a table by thin iron sticks pierced through thermocol with additional weight to support the assembly. The acoustic effect was generated with a frequency generator using computer and notable speakers. The experiments were thoroughly carried out in a quiescent room under normal gravity conditions. Marked dark sheets were used for flow visualization to capture the smoke pattern (Figure. 5). An optical setup was made to obtain shadowgraph of the propagating front which was digitally video graphed. The solid fuel assembly comprised of dried incense sticks in 6.9 cm × 0.20 cm specification. The incense sticks composition is sawdust (30%), charcoal (30%) and cow dung (38.5%) and incense chemical (1.5%). The fuel strips were marked at regular intervals of 1.5 cm to track the smoldering front propagation with time.

Figure 4: Pictorial view of (a) Complete experimental setup (b) reverse smoldering (c) forward smoldering over thin solid fuel.

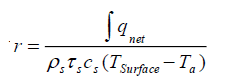

Prior to the experimentation, the fuel strip is cut at the top to enable uniform horizontal ignition across the width. Fuel specimen strips are ignited by exposing it to a pilot flame and special care is taken to remove the moisture which can affect ignition and front spread rate. Every experiment was carried out within 5 minutes to bring room atmosphere back to normally. The readings were taken thrice for same distance and stopwatch was used to measure the split times across the markers. The regression rate (r) is estimated using linear method as:

(1)

(1)

Where, ls ” is length of fuel taken (here, 1.5 cm) and tav ” is the time taken for all three marked distances. From classical theory of ignition spread, assuming unity width of fuel the regression rate (r) is defined by energy balance as:

(2)

(2)

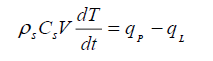

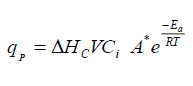

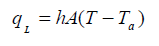

Where, “  ” is Net integrated heat transfer per unit time per unit area to the unburnt fuel, cs ” is Solid-phase specific heat, ρs ” is Solid fuel thickness,τs ” is Solid fuel density, TSurface ” is Surface temperature, Ta ” is Ambient temperature. Ignition is primarily transition from a non-reactive material decomposition to a self-sustained reactive combustion. This transition is owing to an imbalance between the heat production and heat loss which relates to the energy stored in a volume as: Stored energy change = Energy Production-Energy loss

” is Net integrated heat transfer per unit time per unit area to the unburnt fuel, cs ” is Solid-phase specific heat, ρs ” is Solid fuel thickness,τs ” is Solid fuel density, TSurface ” is Surface temperature, Ta ” is Ambient temperature. Ignition is primarily transition from a non-reactive material decomposition to a self-sustained reactive combustion. This transition is owing to an imbalance between the heat production and heat loss which relates to the energy stored in a volume as: Stored energy change = Energy Production-Energy loss

(3)

(3)

The energy production is based on an Arrhenius approximation as:

(4)

(4)

The associated heat energy loss is taken by assuming constant concentration of reactants in the volume (material not consumed prior to ignition) (Ci) indicating a uniform temperature.:

(5)

(5)

Where, qP ” is the Energy production, qL ” represents Energy loss, V” is the volume, T” is the temperature and t” represents time, ΔHC ” is the heat of combustion, Ci ” represents the Concentration of reactants, A* ” is the Pre-exponential factor, Ea ” is the Activation energy, R ” is the Universal gas constant., h ” is the convection factor.

Results

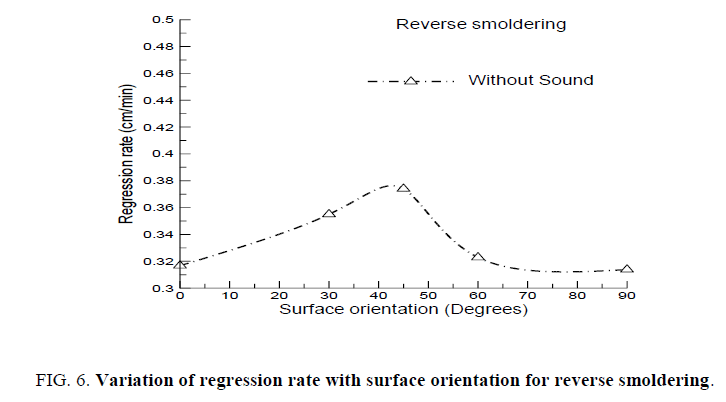

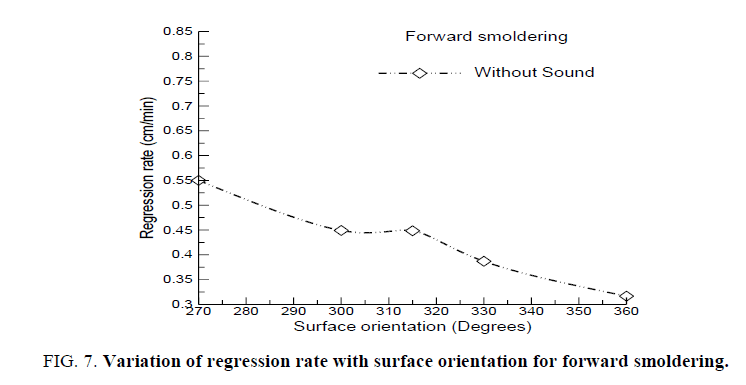

Systematic experiments were carried out to understand acoustic effects on smoldering combustion in purely convective environment. Prior to the main study, experimental predictions were corroborated with the well-established smoldering studies. The effect of surface orientation on regression rates at selected orientations for reverse (Figure 6) and forward modes (Figure. 7) was assessed. According to classical heat transfer theory over thin solid fuels, the propagating front spreads by the heat feedback (forward heat transfer) from the burning to the unburnt solid fuel upstream. The extent of heat feedback is reflected in regression rates (equation 2). Experimentation show that both reverse and forward smoldering modes are affected by surface orientation variation with regression rate following a non-monotonic trend. For the case of reverse smoldering, at horizontal orientation, the buoyant velocity on the unburnt fuel surface is zero resulting in regression rates purely to be a product of conduction heat transfer to the unburnt fuel and ash. For vertical surface orientation, the heat transfer to the unburnt fuel is still primarily owing to conduction but the ash is in convective environment with high temperature buoyant smoke moving upward across it and reducing heat loss to surroundings. The regression rates are nearly same for both the horizontal and vertical orientations due to competing effects of two aspects viz., less smoke velocity resulting low heat loss from smoldering front to smoke and lower heat loss from ash to surrounding resulting in reduced heat loss from smoldering to ash. As the orientation surface orientation increases, both effect increases and reaches a peak value at an inclination of 45° representing minimum heat loss case for reverse smoldering. With further orientation increase, the conduction effect drops owing to buoyant smoke deviating upward and not heating the ash resulting in non-monotonic variation till vertical orientation. Similarly, for forward smoldering case, the buoyant convection assumes dominating role apart from conduction and radiation with maximum at 270°. Buoyant high temperature smoke carries heat moving parallel to fuel surface supplying additional energy and preheating. High regression rates can be attributed as a consequence of heightened cumulative heat transfer to the unburnt fuel. The conductive heat transfer is elevated by the presence of ash which is heated by the hot smoke. For upward spread, the convection is dominant and smoke gravitates upward with least contribution to the ash. The spread in this configuration is so fast that it is difficult to prevent forward smoldering fires in inclined orientations. The results also represent base case for the present work (without sound) and is utilized to compare with similar experiments performed with sound.

The smoldering process is elevated owing to strong convection preheating the unburnt fuel. As the surface orientation increases till horizontal, the convective effect drops to minimum at 360o or horizontal and is reflected in respective regression rates. The experimental results were validated with Tiwari et. al. [26] and matches reasonably well indicating that the setup and experimental predictions would be able to give good physical insight into the external acoustic effect on smoldering process.

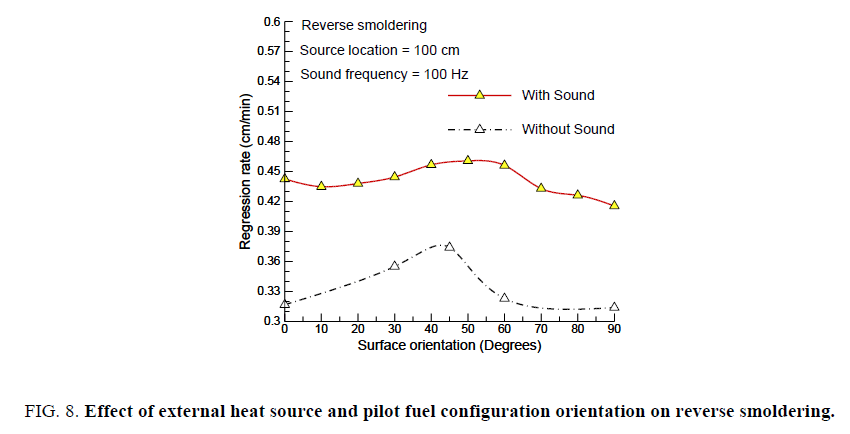

First, the acoustic effect on reverse smoldering with varying surface orientation is investigated. Figure. 8. shows the variation of regression rate with surface orientation in presence of an external sound source at a fixed distance for a selected frequency. Looking at the plot one can note that, sound significantly affects the reverse smoldering process. The effect of sound broadly follows the same trend as seen without the source. The acoustic effect was noted to reduce non-monotonicity of the regression rate curve and enhancing the regression rates for all surface orientations. Quantitatively, as surface orientation increases, the rate of change in regression rates drops and then rises gradually in the same range with further increase. The maximum regression rate change (rise) was observed to occur at surface orientation of 60° by ~42% whereas, the minimum rise was noted for 45° inclination by ~25%. In retrospect to the without sound case, a close rise of ~40% and ~36% were evaluated for horizontal and vertical orientations.

Figure 8: Effect of external heat source and pilot fuel configuration orientation on reverse smoldering.

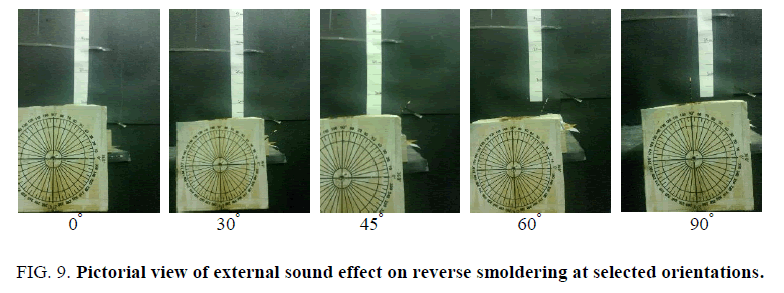

Figure. 9. shows the pictorial interpretation for selected reverse smoldering cases. The reduced convection contribution and significant role of ash in preventing heat loss can be seen. The change owing to the presence of sound is simplified in terms of energy added from sound to ignition front or lost from smoldering to sound (please refer equation 3). Reverse smoldering is known for reduced buoyant velocity (reduced heat loss) at horizontal and reduced heat loss owing to ash in vertical orientation. With acoustics, the enhanced effects but lower variance with respect to surface orientation is due to the dominating acoustic quantities effect over other parameters like magnitude of the convection velocity. Presence of sound strongly alters localized temperature and velocity flow field around the smoldering front zone causing significant energy transfer from sound to the ignition front. A part of this additional energy is subsidized to the higher forward heat transfer to the ignition front thus increasing chemical reaction rates to result in boosted regression rates.

The overall acoustic dominance can be ascribed to the sound source being fixed. Since in reverse smoldering, the smoke does not contribute to the forward heat transfer and, the post fuel region is dominated by the acoustics replicated by little effect of change in regression rate with the surface orientation.

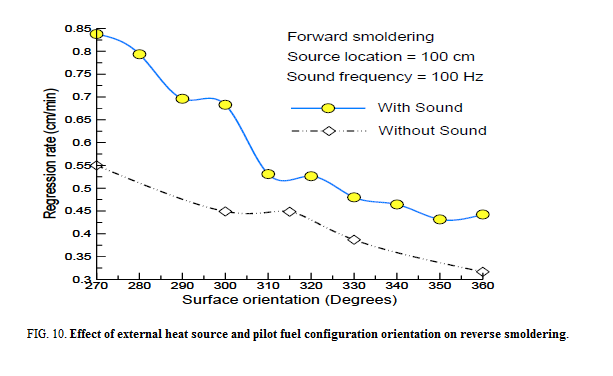

Forward smoldering mode dominates spreading phenomenon by the ensuing higher regression rates owing to the strong convection currents. The presence of an external sound source in immediate vicinity strongly affects the forward smoldering combustion (Figure. 10). The regression rates follow similar monotonic drop with increase in surface orientation as without sound case however, acoustics was noted to support higher regression rates at all the surface orientations. Quantitatively, maximum rate of change(rise) was noted for upward spread (270°) of ~53% and minimum at an inclined surface orientation of 315° 18%. With increase in surface orientation, the rate of change of regression rate drops considerably till 315° followed by an invariant rise.

Figure 10: Effect of external heat source and pilot fuel configuration orientation on reverse smoldering.

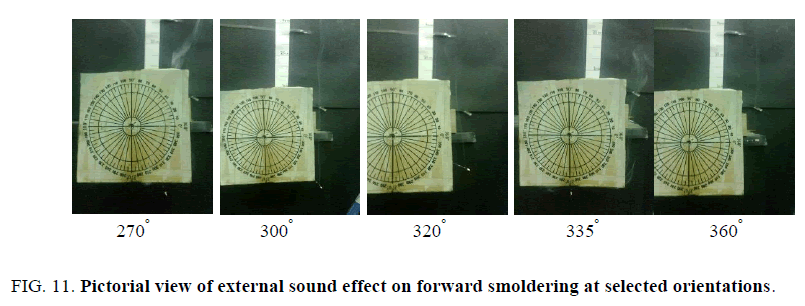

Pictorial view of the forward smoldering at selected surface orientations show the direction of smoke and varying flow field (Figure. 11). Careful observation of the flow patterns was carried out and compared with the similar cases of without sound. The effect of acoustics is to enhance heat transfer to the fuel, which acts in concordance with the smoke resulting in very high regression rates. The effect reduces at higher orientations (nearing horizontal) due to diminishing effect of smoke induced heat. Which indicates the entire effect is due to acoustics alone. As estimated experimentally, acoustics from an external sound source at a fixed location and for a fixed frequency with varying surface orientation results primarily acting as a potential Heat Source” with energy being transferred from sound to the smoldering front. The acoustic effects dominate reverse smoldering process and assists convection currents in forward smoldering. It is important to note that the above stated observations were accounted for fixed external source distance and sound frequency. This demands the role of external sound source location to be probed. Next, the sound source location effect was investigated on downward and upward spread smoldering process. Figure. 12 shows the regression rates variation with varying separation distance between sound source and smoldering pilot fuel for downward spread (90°in comparison to without sound case.

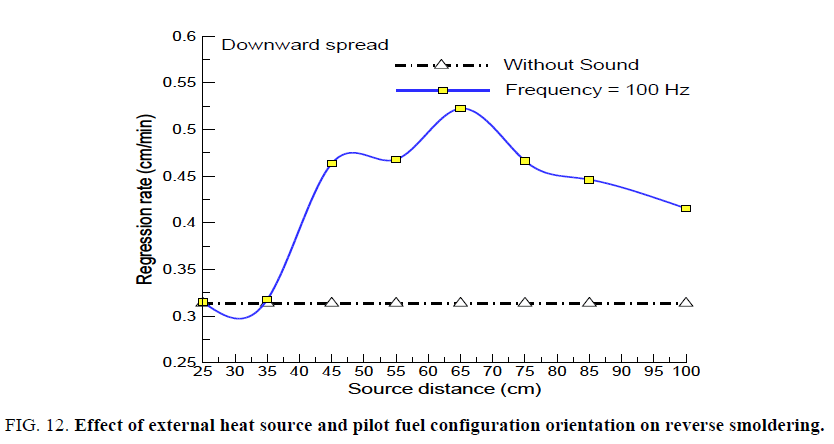

Figure 12: Effect of external heat source and pilot fuel configuration orientation on reverse smoldering.

The Heat Source” effect of acoustics can be noted to emerge with source location. Systematic variation in source location for a fixed frequency was noted to result in a non-monotonic regression rate variation. Reduction in separation distance reports a rise in regression rate till peak (here, 65 cm representing ~67% rise) and drop with further decrease to the minimum value (here, 25 cm representing nearly similar to the without sound). In comparison to the acoustic effect with source placed at 100 cm, reduction in separation distance results in enhanced regression rate till 42 cm following a non-monotonic trend. Further reduction in separation distance drops regression rate to the lowest viz., without source. Two standard neutralizing locations exist where regression rate matches without sound (here, 25 cm and 35 cm) for the same sound frequency. Enhanced regression rate till a selected distance (here, 42 cm) suggests additional energy transfer from sound to ignition front (as compared to source at 100 cm for fixed frequency) and drop with further reduction as sound source comes closer to the ignition front indicating the sound source location as a key controlling parameter of smoldering. Downward spread under sound influence is controlled by the strong acoustics and upward moving hot smoke supplying heat to ash which prevents heat loss. The additional rise in regression rate as source is bought closer to pilot fuel may be attributed to the development of strong gradients pressure, temperature and velocity flow field across immediate vicinity of ignition front. The interactions are likely to be more intensely associated to the compression front of the sound wave resulting in the acoustics effect dominance reflected in regression rate. The drop-in regression rate with reduction in source separation distance till minimum (25 cm), indicates the drop in acoustic effect owing to enhanced interaction of rarefaction part. Similar to the compression front interactions and resultant localized field development, the intensity of rarefaction-smoldering front interaction intensifies as source comes closer to the smoldering fuel. The acoustic effect can be noticed till 35 cm with regression rate higher than without sound. The variations in these compression-rarefaction interactions (acoustic strength) with smoldering front are noted with the upgoing smoke patterns.

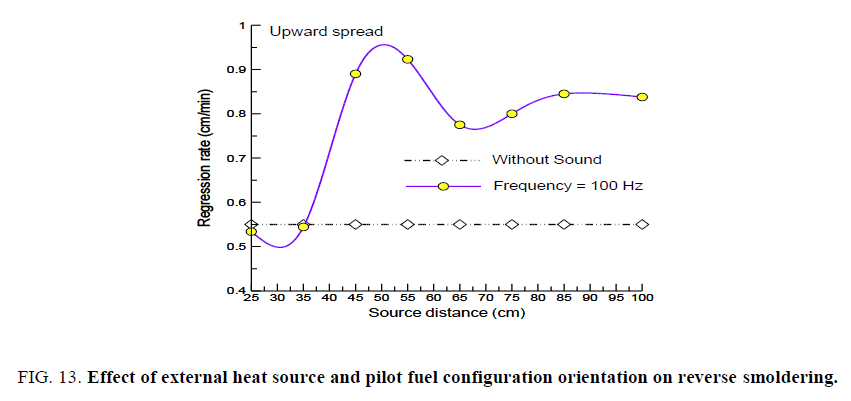

For upward spread, trend similar to downward spread was noticed with acoustics Heat Source” effect with varying source location (Figure. 13). Reduction in separation distance reports a rise in regression rate till peak (here, 50 cm representing ~68% rise) and drop with further decrease to the minimum value (here, 25 cm representing ~3% drop) than without sound. In comparison to the acoustic effect at 100 cm, separation distance reduction results in a non-monotonic trend with recurrently low regression rate values. Enhanced regression rates were noted for separation distance range of 45 cm to 65 cm and 85 cm to 95 cm than acoustics effect at 100 cm. For remaining source location under study, drop in regression rates was noticed. Similar to the downward spread, the nearest zone to the smoldering front viz., 25 cm to 35 cm, results in regression rate nearly equal to the without sound on the lower side. Two source location zones were established for cases of downward and upward spread viz., a neutralizing zone with regression rates nearly same as without sound (25 cm to 35 cm) and abrupt rise zone representing drastic rise in regression rate (35 cm to 50 cm for the same sound frequency. Upward spread is dominated by the strong convection currents and assisted by the external sound source at a fixed separation distance for a fixed frequency. The variation in regression rate with reduction in separation distance indicates sound source location as a governing parameter. Nearby placement of external sound source reduces regression rate for both upward and downward spread indicating minimized acoustic effect owing to excessive heat loss from smoldering front to the sound. With further increase in separation distance, a sudden rise was noticed indicating evolving acoustics effect to the ignition process.

Figure 13: Effect of external heat source and pilot fuel configuration orientation on reverse smoldering.

Conclusion

An experimental exploration was carried out on incense sticks to identify the merits of acoustic effects on smoldering combustion. Reverse and forward smoldering modes were investigated with controlling parameters viz., fuel surface orientation and sound source distance for a fixed frequency. The specific conclusions of the study details that:

• Smoldering combustion is severely affected by the presence of an external sound source.

• Acoustic effect dominates in reverse smoldering resulting in noteworthy rise at all orientations. The maximum and minimum effect was observed at surface inclination of 60° and 45° respectively whereas, the horizontal and vertical orientations experience a significant close range rise.

• Forward smoldering experiences higher regression rate change due to conjunction of sturdy convective heat transfer assisted by the acoustic effects. The change due to acoustics follow similar trend as without. The maximum and minimum change was noted at 270° and 315°. The rate of change drops from upward spread to the minimum and then rises gradually to become invariant till horizontal orientation.

• Formation of strong gradient grounded localized temperature and velocity fields in the immediate vicinity of smoldering controls the relevant energy transfer and consequently the chemical reaction rate decides the acoustic effect outcome under subjected condition.

• External sound source location is the governing parameter which directs the acoustic effect on selected cases of downward and upward spread. Reduction in separation distance results in positive acoustic effect (additional regression rate rise) for smoldering combustion till maximum value and then drops to minimum value (without sound). The maximum acoustic effect was noted occur at an intermediate sound source location whereas, the minimum effect was evaluated to occur with nearby placement of sound source for both cases of downward and upward spread. Two distinct zones were established based on external sound source location indicating no effect (nearby placement) and drastic rise (next to no effect zone) for upward and downward spread. The intensity of compression-rarefaction front interaction with smoldering front varies with source location and primarily controls the energy transfer.

Application of the work

Almost all combustion processes are accompanied by the presence of sound. The division is external (outside) and internal (produced due to combustion). The low speed combustion experiments are noted to neglect the acoustic effects. Smoldering poses serious hazards on operational engineering systems on earth and in space. Utilization of sound for better combustion offers an attractive alternative. Present work would be very useful for scientific, engineering, practical and functional applications involving smoldering combustion and mitigation on earth and in space. The work offers seamless physical insight into acoustic effects on smoldering combustion being more harmful than the normal combustion with abrupt rise and demands proper attention and prevention. These results can be used in various terrestrial and space applications viz., to design, validate, test engineering systems, smoldering combustion alerts, prevention from expectedly transition to fires, minimizing smoldering damages, hazards, saving life and environmental pollution control.

References

- Semenov NN. “Chemical Kinetics and Chemical Reactions”. Clarendon Press, Oxford; 1935.

- Palmer KN. “Smoldering combustion in dusts and ?brous materials”. Combust Flame. 1957;2(6):129-54.

- Browne FL. “Theories of the combustion of wood and its control”. Tech Rep. 2136, USDA Forest Products Laboratory; 1958.

- Bowes PC, Thomas PH. “Ignition and extinction phenomena accompanying oxygen-dependent self-heating of porous bodies”. Combust Flame. 1966;10(3):221-30.

- Kinbara T, Endo H, Sega S. “Downward propagation of smoldering combustion through solid materials”. SympInt Combust. 1967;11(1):525-31.

- Moussa NA, Toong TY, Garris C. “A Mechanism of smoldering of cellulosic materials”. SympInt Combust. 1977;16(1):1447–57.

- Ohlemiller TJ, Rogers FE. “A survey of several factors in?uencing smoldering combustion in ?exible and rigid polymer foams”. J Fire Flammabl. 1978;9(4):489-509.

- Ohlemiller TJ. “Smoldering combustion hazards of thermal insulation materials”. Tech Rep NBSIR 81-2350, National Bureau of Standards; 1981.

- Ohlemiller TJ, Lucca DA. “An experimental comparison of forward and reverse smolder propagation in permeable fuel beds”. Combust Flame. 1983;3(12):131-147.

- Ohlemiller TJ. “Modeling of smoldering combustion propagation”. Prog. Energy Combust. Sci. 1985;11(4):277–310.

- Ohlemiller TJ. “Smoldering combustion”. Tech. Rep. 85-3294, National Bureau of Standards; 1986.

- Drysdale D. “An Introduction to Fire Dynamics”, 2ed Wiley, Chichester; 1999:261-89p.

- Beever PF. “Initiation and propagation of smoldering reactions (Ph.D. thesis)”. University of Leeds; 1986.

- Jones JC, Wake GC. “Measured activation-energies of ignition of solid materials”. J ChemTechnolBiotechnol. 1990;48(2):209-16.

- Leach SV, Rein G, Ellzey JL, et al. “Kinetic and fuel property effects on forward smoldering combustion”. Combust Flame. 2000;120:346-58.

- Babrauskas, V. “Ignition Handbook: Principles and Applications to Fire Safety Engineering, Fire Investigation, Risk Management and Forensic Science”. Fire Science Publishers/SFPE, Issaquah, WA; 2003:302-04p.

- Rein G. Computational model of forward and opposed smoldering combustion with improved chemical kinetics; 2005.

- Kampen JV. “Acoustic pressure oscillations induced by Confined Turbulent Premixed natural gas flames”. PhD thesis, University of Twente, Enschede, Netherlands; 2006.

- Hagen BC. “Onset of smoldering and transition to ?aming ?re”, PhD Thesis, Department of Physics and Technology, University of Bergen; 2013.

- Ohlemiller TJ. “Smoldering combustion propagation through a permeable horizontal fuel layer”. Combust Flame. 1990;81(9):341-53.

- Rein G. “Smouldering combustion phenomena in science and technology”. International Review of Chemical Engineering. 2009;13-18.

- Krivokorytov MS, Golub VV, Volodin VV. “The Effect of Acoustic Oscillations on Diffusion Combustion of Methane”. Tech Phys Lett. 2012;38(5):478-80.

- Dowling, AP, Mahmoudi Y. “Combustion noise”. Proc Combust Inst. 2014;35:65-100.

- Tiwari P, Malhotra V. Proceeding of International Conference on Emerging Trends in Engineering and Technology, Hyderabad, India; 2016.

- Dowling AP. “Vortices, sound and flames a damaging combination”. Aeronaut j. 2016;104:105-16.

- Tse SD, Anthenien RA, Fernandez-Pello AC, et al. “An application of ultrasonic tomographic imaging to study smoldering combustion”. Combust Flame. 1999;116:120-35.

- Chiu HH, Summerfield M. “Theory of Combustion Noise”, Aerospace and Mechanical Sciences Report, Princeton University, Princeton, New Jersey; 1973.