Original Article

, Volume: 11( 2)Mechanical and Dynamic Behaviour of Epoxy/MWCNTS and Epoxy/Al2O3 Nanocomposites

- *Correspondence:

- Mohammed SM, Mechanical Engineering Department, Shoubra Faculty of Engineering, Benha University, Cairo, Egypt, Tel: +841673326268; E-mail: eng.shaimaa2012@gmail.com

Received: November 16, 2017; Accepted: November 30, 2017; Published: December 07, 2017

Citation: Mohammed SM, Gamil M, Mohammed SS, et al. Mechanical and Dynamic Behaviour of Epoxy/Mwcnts and Epoxy/Al2O3 Nanocomposites. Nano Sci Nano Technol. 2017;11(2):121

Abstract

The mechanical and dynamic behaviors of Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites were investigated in this study. Tensile and impact properties were measured for the two nanocomposites. Free vibration test was applied to measure frequency responses and damping factors. The results showed a reduction in the mechanical properties as well as the damping factors. Frequency response and damping factor was strongly affected by the weight percent of the nanofillers. MWCNTs enhanced the bonding between the Epoxy resin and nanotubes causing reduction in the ability to dissipate energy and improvement in stiffness. The results also demonstrated that, the natural frequency of nanocomposites was increased by increasing the weight percent of nanofillers. The damping factor has the same down trend with the mechanical properties of the nanocomposites.

Keywords

Nanocomposites; Tensile properties; Natural frequency; Damping factor

Introduction

In the recent years, there is a great attention toward nanocomposite techniques to enhance the performance, mechanical and dynamic properties [1,2]. Especially, the polymeric matrix based nanocomposites reinforced with small percentages of strong nanofillers. Recognizing of their unique properties, it has been used for a wide range of applications such as aerospace industries, aircraft, coating, automotive, and marine engineering [3]. Among various types of polymeric matrices, Epoxy resin is the most polymer matrix used for advanced nanocomposite. The Epoxy matrix exhibit high stiffness and good adhesion to the embedded reinforcement.

Recent research articles focus on polymeric matrix embedded with MWCNTs. They offer more advantages and attracting scientific and industrial interest due to their unique characteristics [4]. Addition of small amount of MWCNTs to the polymeric matrix can improve the nanocomposites stiffness. However, large specific surface areas of MWCNTs caused the ability to agglomerate, which decline the nanocomposites strength as the results of inhomogeneous dispersion and stress concentration in the polymer matrix [5]. It is recognized that carbon nanoparticles enhance the yield and fracture strength of polymeric matrix [6-9]. However, Laurenzi et al. [10] showed the reduction of tensile properties of MWCNTs reinforced Epoxy matrix.

Ceramic-polymer nanocomposites have a great potential for industrial applications. They combine hardness, stiffness and wear resistance of ceramics and elasticity of polymer [11]. Nanomaterials defined as the nanoparticles with dimensions smaller than 100 nm [12]. Many studies demonstrated that nanomaterials exhibit enhanced properties, which forward with increasing the contents of nanoparticles [13]. Ceramic nanoparticles such as Al2O3 play an important role in the nanocomposite techniques due to their ability to enhance the mechanical characteristics. Their nanometer scale and extra ordinary characteristics make them unique nanofillers for multifunctional composites and structures [14]. Many researchers study the influence of nanoparticles on the nanocomposite properties. Devendra et al. [15] showed the reduction of tensile and impact properties of Epoxy matrix with addition of various amounts of Al2O3.

During the past years, it has become most important to resist impact noise and vibration. From this point of view, mechanical dampers have been investigated and developed and so, the utilization of damping materials is a key point to produce efficient damping to eliminate vibration and noise. Damping materials must have good ability to reduce strain energy when subjected to vibratory loads. They have been widely used in the high performance structural applications fields such as construction, aerospace, marine, etc. Damping is a significant modal parameter for the structures design in which cyclic loading and vibration control are critical. Damping affected by different environmental parameters, such as amplitude of stress, frequency, static preload and temperature. Damping affected also by grain size, corrosion fatigue, number of fatigue cycles and porosity [16].

Few researchers investigated the effect of MWCNTs and Al2O3 on the damping properties of polymeric composites. Kordani et al. [14] investigated the enhanced natural frequency of polymeric nanocomposites reinforced with various wt% of MWCNTs. Shiuh et al. showed the reduction in damping ratio with increasing of MWCNTs wt% into Epoxy matrix. Man et al. [17] investigated the declining of both toughness and damping properties with incorporation of MWCNTs into polymer based nanocomposites. Khashaba [18] studied the improvement of frequency of Epoxy/Al2O3 nanocomposites.

In the present investigation, the mechanical and dynamic behavior of the Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites were studied. The effect of nanocomposites wt% on the mechanical properties, natural frequency and damping factor was investigated. The results showed reduction in the damping properties with toughness and tensile strength.

Experimental Procedure

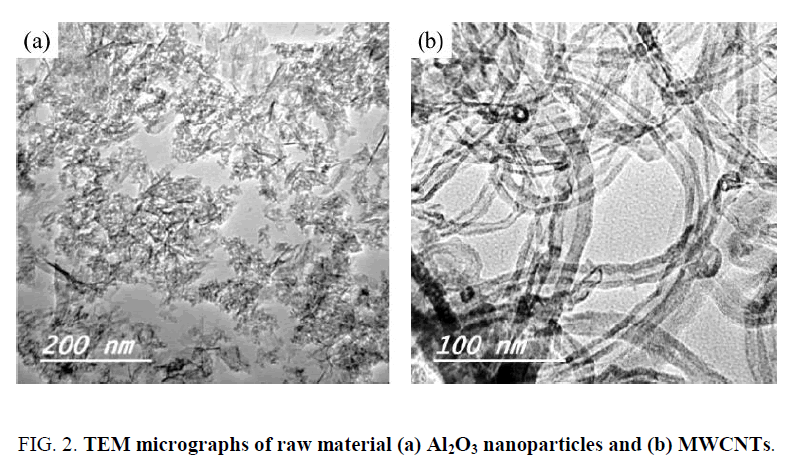

Epoxy resin (Kemapoxy 150) was used as a polymeric matrix in this study with general chemical formula shown in Figure 1. Nanocomposites were prepared by adding MWCNTs with inner and outer diameters of 20 nm and 30 nm, respectively, and Al2O3 nanoparticles have an average diameter of 10 nm. Figure 2 (a) and (b) shows TEM image of Al2O3 nanoparticles and MWCNTs, respectively. It was found from Figure 2 (a) that Al2O3 nanoparticles are almost needle and irregular spherical shape, also the size of nano Al2O3 is well proportioned. Figure 2 (b) shows that the purified MWCNTs show smooth and uniform surface morphology, the outer diameters were almost consistent with the data provided by the supplier. Nanofillers with 0.25 wt%, 0.5 wt%, 0.75 wt% and 1 wt% were added to the resin to prepare nanocomposites and then stirred mechanically for twenty minutes at room temperature, using SUPERMIX homogenizer (model DEPOSE), then the hardener was added to the mixture by the ratio 2:1 by weight and then stirred mechanically again for ten minutes. The mixture poured in a silicon moulds have dimensions suitable for the required test according to test standards. Finally, the mixture was allowed to fully harden at room temperature for 7 days according to the specification of the Epoxy matrix.

Figure 1: The chemical formula of the Epoxy mer [19].

Tensile test of the nanocomposites was performed according to ASTM D 638-03 standard, using the (Instron) universal testing machine with a load cell of 5 KN and a constant speed of 10 mm/min. Three specimens for each condition were tested. The load displacement results were analyzed to calculate the tensile strength of nanocomposite specimens.

Charpy impact test was performed according to DIN-ISO179. The impact strength of the composites was measured using notched specimen with rectangular dimensions of 80 × 10 × 4 mm3. Charpy impact strength-testing machine (HIT 50P Zwick/Roell) was used with a pendulum energy 0.5 Joule and angle of inclination (fall angle) 106.38o at room temperature. The distance between the supports was set to 60 mm. three specimens of each condition were tested and the average values of the data are reported.

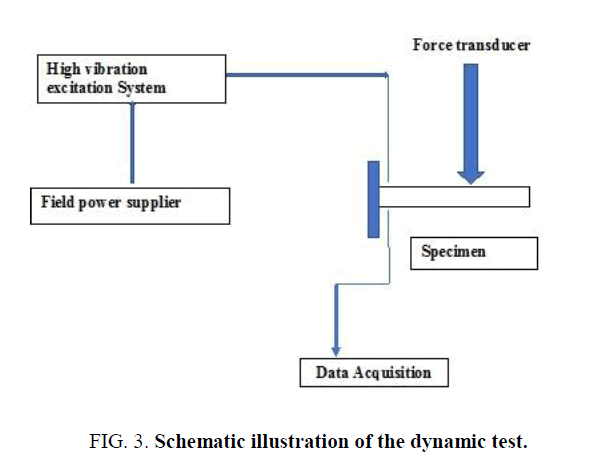

Rectangular specimens having 200 × 20 × 4 mm3 were examined. The composite beam without nanofillers and the nanocomposite beam with MWCNTs and Al2O3 were used as samples for the damping test. To investigate the damping factor and natural frequency characteristics, an experimental study were performed using vibration testing equipment illustrated in Figure 3. A force transducer (BK8230) was attached from one side of the specimen to measure the input force. An accelerometer (DeltaTron-4507 B) was attached from the other side of the sample to detect acceleration. Data Acquisition, software for vibration analysis (LabVIEW) and computer to display the result analysis also attached. The sample was in a free-free boundary condition and also excited by a shaker (BK4828). The frequency response function (FRFs) was examined using an Analyzer in a conventional modal testing procedure.

Results and Discussion

Tensile strength of the nanocomposites

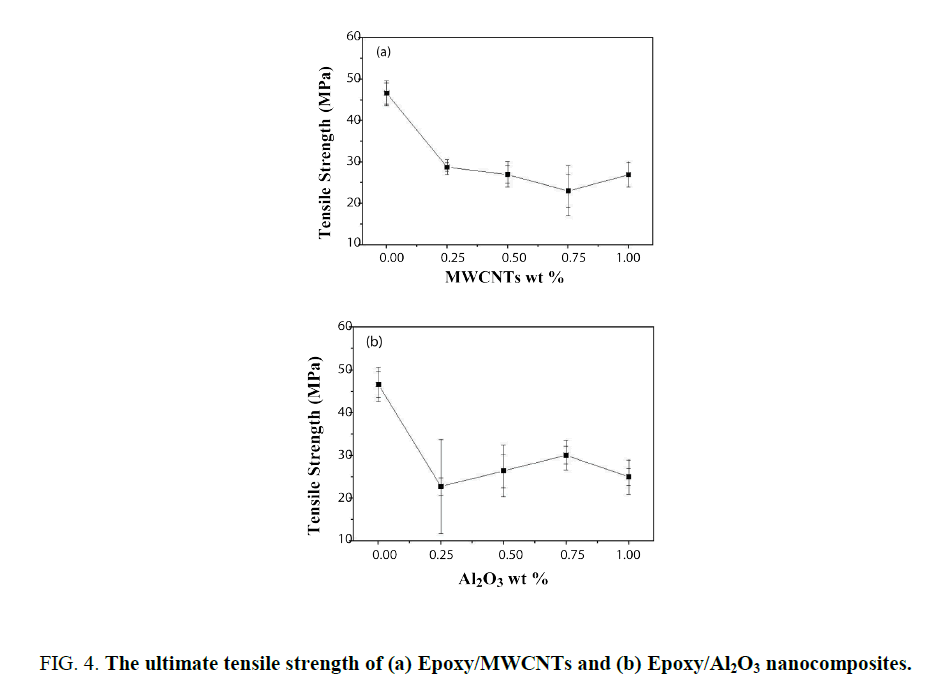

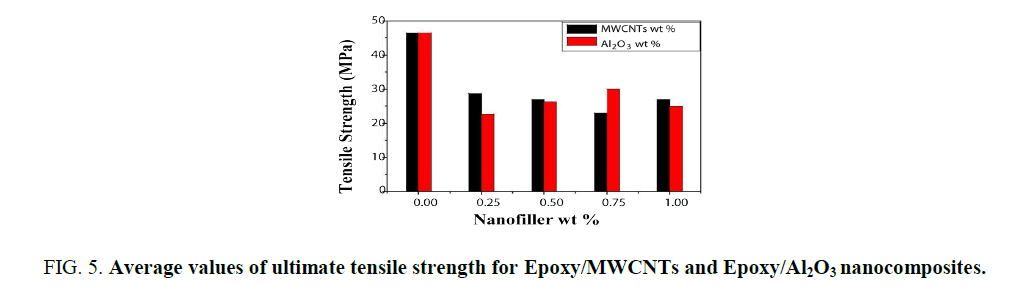

Table 1 shows the mechanical and dynamic properties of the two nanocomposites. The tabulated results show a reduction in damping factor with respect to toughness reduction. Figure 4. (a) and (b) show the ultimate tensile strength of Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites, respectively, for various wt%. Figure 5. shows the average tensile results of the neat Epoxy and the two nanocomposites. Generally, the results revealed that dispersion of both MWCNTs and Al2O3 nanopaticles tend to reduce the ultimate tensile strength of the nanocomposites. The Epoxy/MWCNTs nanocomposites exhibited slightly higher tensile strength when compared with the Epoxy/Al2O3 nanocomposites. The tensile strength of Epoxy/Al2O3 increased with increasing the Al2O3 nanoparticles up to 0.75 wt% and then decreased at 1 wt%. The increasing was due to the homogenous distribution of the hard-ceramic nanoparticles into the Epoxy matrix. On the other hand, the decreasing at 1 wt% was due to the excess nanofiller in the nanocomposites which cause damage matrix continuity and void formation. These results are in agreement with Gojny et al. [20].

Figure 5: Average values of ultimate tensile strength for Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites.

| Composite type | Tensile strength (MPa) | Strain at break | Impact energy (KJ) | Frequency (Hz) | Damping ratio % |

|---|---|---|---|---|---|

| Neat Epoxy | 46.59 | 0.053 | 60 | 313 | 3.37 |

| Epoxy/0.25 wt% MWCNTs | 28.79 | 0.033 | 57 | 492 | 3.21 |

| Epoxy/0.5 wt% MWCNTs | 27.02 | 0.0307 | 54 | 472 | 3.2 |

| Epoxy/0.75 wt% MWCNTs | 23.08 | 0.029 | 52 | 406 | 2.89 |

| Epoxy/1 wt% MWCNTs | 26.98 | 0.027 | 50 | 390 | 1.89 |

| Epoxy/0.25 wt% Al2O3 | 22.77 | 0.024 | 58 | 1136 | 3.1 |

| Epoxy/0.5 wt% Al2O3 | 26.4 | 0.03 | 58 | 928 | 2.8 |

| Epoxy/0.75 wt% Al2O3 | 30.07 | 0.034 | 56 | 922 | 2.4 |

| Epoxy/1 wt% Al2O3 | 25 | 0.0323 | 52 | 751 | 1.68 |

Table 1: Mechanical and dynamic properties of Epoxy nanocomposites.

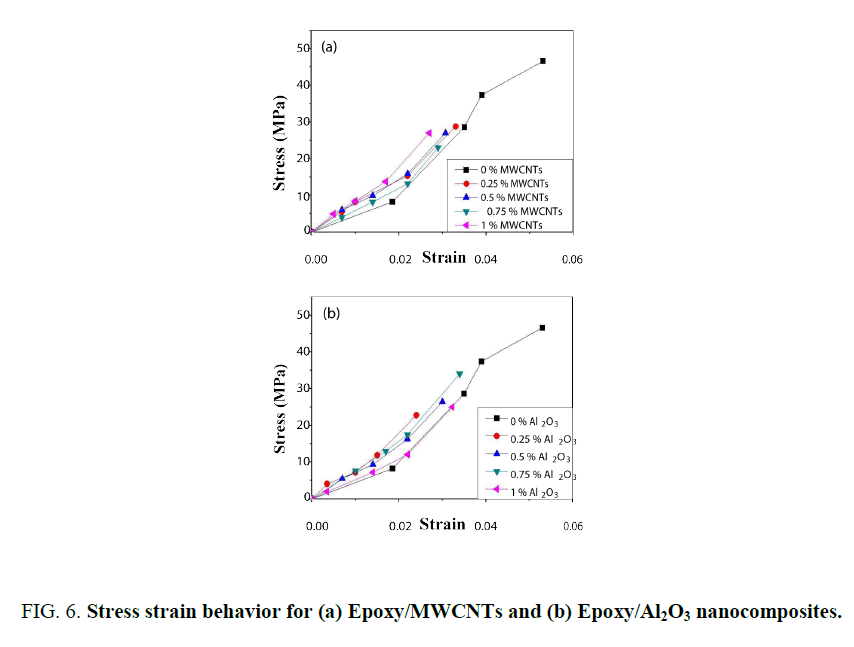

Figure 6 (a) and (b) shows the stress strain behavior of Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites. The results show that the breaking strain was declined with the nanofillers addition. Little effect in breaking strain was observed for excess wt. % of nanofillers as shown in Figure 5 (a) and (b). The reduction in strain might be due to incorporation of rigid nanofillers into a polymeric matrix; this indicates the brittle behavior of the nanocomposites due the formation of nano defect results in regional stress concentration in the matrix.

Figure 6: Stress strain behavior for (a) Epoxy/MWCNTs and (b) Epoxy/Al2O3 nanocomposites.Stress strain behavior for (a) Epoxy/MWCNTs and (b) Epoxy/Al2O3 nanocomposites.

Impact energy of the nanocomposites

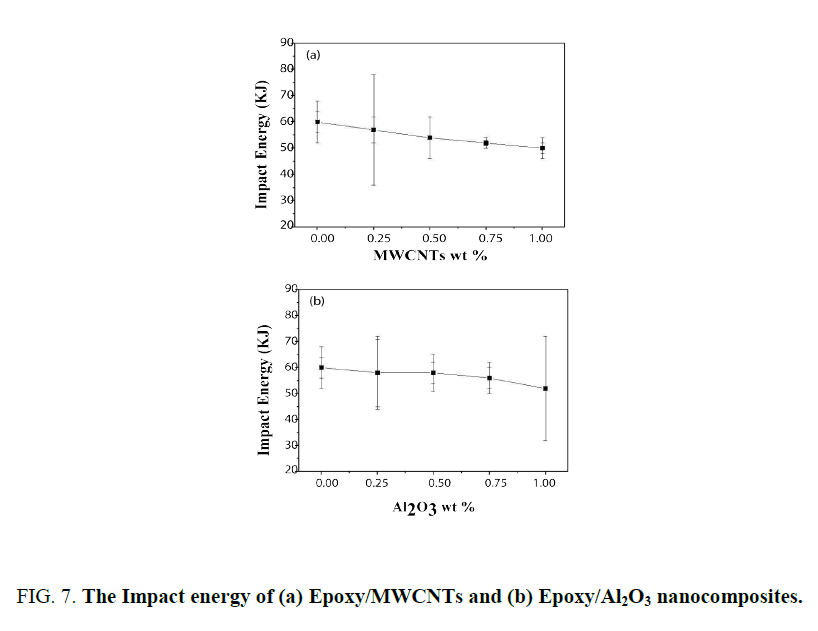

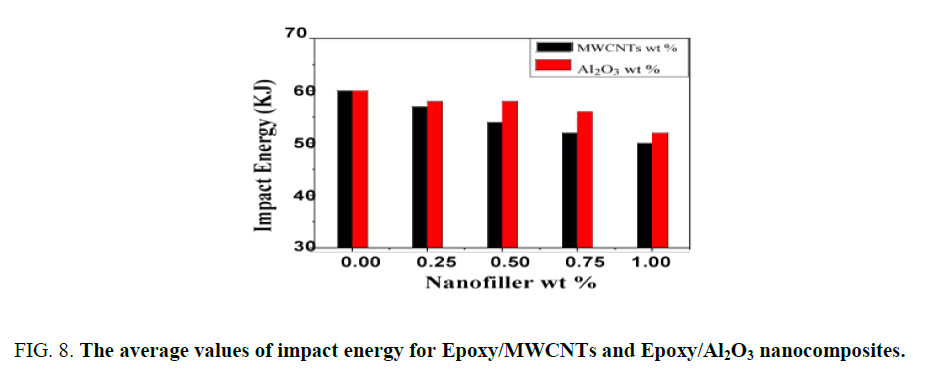

The impact behaviour of materials is directly related to the toughness [21]. Figure 7 (a) and (b) shows the impact energy of Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites, respectively, for various values of each sample. The variation of the average values of impact energy of the nanocomposites with the wt% of the nanofillers is illustrated in Figure 8. The results revealed that both Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites exhibit slightly lower impact energy than the neat Epoxy. Epoxy/Al2O3 nanocomposite exhibits higher impact energy than Epoxy/MWCNT nanocomposite. This is due to the good bonding strength between Al2O3 and matrix and that prevents the cracks initiation effectively.

Figure 7: The Impact energy of (a) Epoxy/MWCNTs and (b) Epoxy/Al2O3 nanocomposites.

Figure 8: The average values of impact energy for Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites.

The addition of MWCNTs tends to reduce the impact strength of the neat Epoxy. This may be due to the brittleness of the MWCNTs, their capability to form agglomerates, which caused stress concentrations. Similar results have been observed by Haiyan et al. [22]. Declined of Impact behaviour with addition of nanofillers may be explained that a polymer matrix with nanofillers loading has weak ability to absorb impact energy. This phenomenon is due to matrix continuity is interrupted by the fillers, and each fillers is a position of stress concentration, which can act as crack initiator and decrease the adhesion and ability of composite to absorb energy [15].

SEM micrograph of fracture surfaces

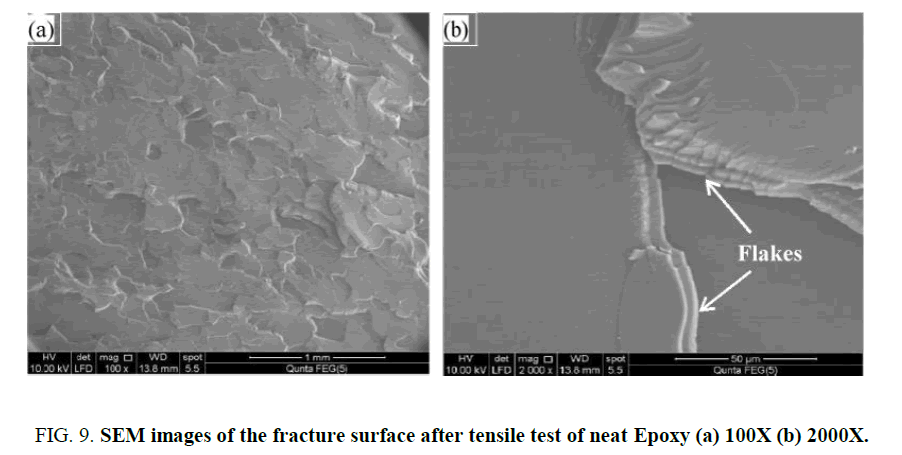

SEM examinations reflected detailed information about the cause of failure. The SEM images of tensile fracture surfaces of neat Epoxy and nanocomposites are shown in Figure 9 and 10 (a) smooth fracture surface was seen in Figure 9 at magnification of 100X and 2000X, respectively, which indicates a brittle fracture for the neat Epoxy.

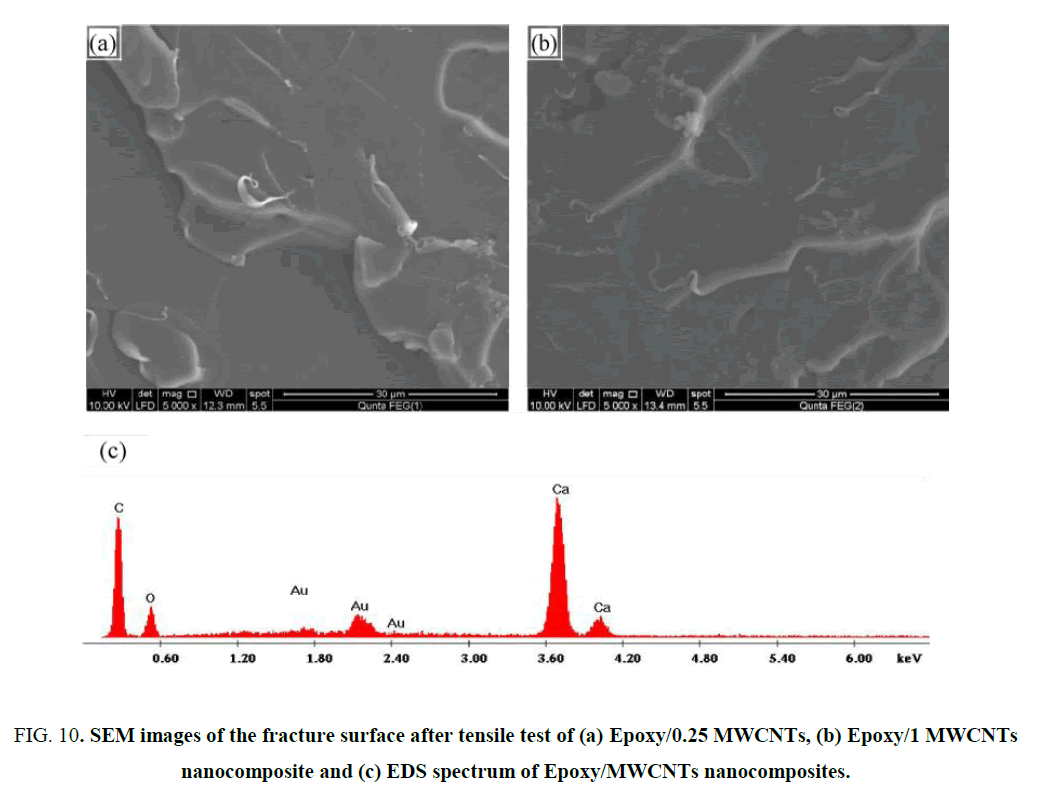

Figure 10 (a) and (b) shows the fracture behavior of Epoxy/0.25 MWCNTs and Epoxy/1 MWCNTs, respectively, the fracture surface becomes rough, as the surface indicates; a good random distribution of MWCNTs into the Epoxy matrix was achieved. The rough fracture surface of the Epoxy/MWCNTs nanocomposites is due to the crack propagation which prevents the transformation of stress from the matrix to the reinforcement. These cracks reduce the tensile strength of the nanocomposites with respect to the neat resin. Figure 10 (c) shows the EDS spectrum of MWCNTs nanocomposites, it was seen that the elements of MWCNTs with a wrapping layer contain calcium, carbon, oxygen and gold from the coating process. The agglomeration of impurities of calcium may cause reduction in tensile behaviour of the nanocomposites.

Figure 10: SEM images of the fracture surface after tensile test of (a) Epoxy/0.25 MWCNTs, (b) Epoxy/1 MWCNTs nanocomposite and (c) EDS spectrum of Epoxy/MWCNTs nanocomposites.

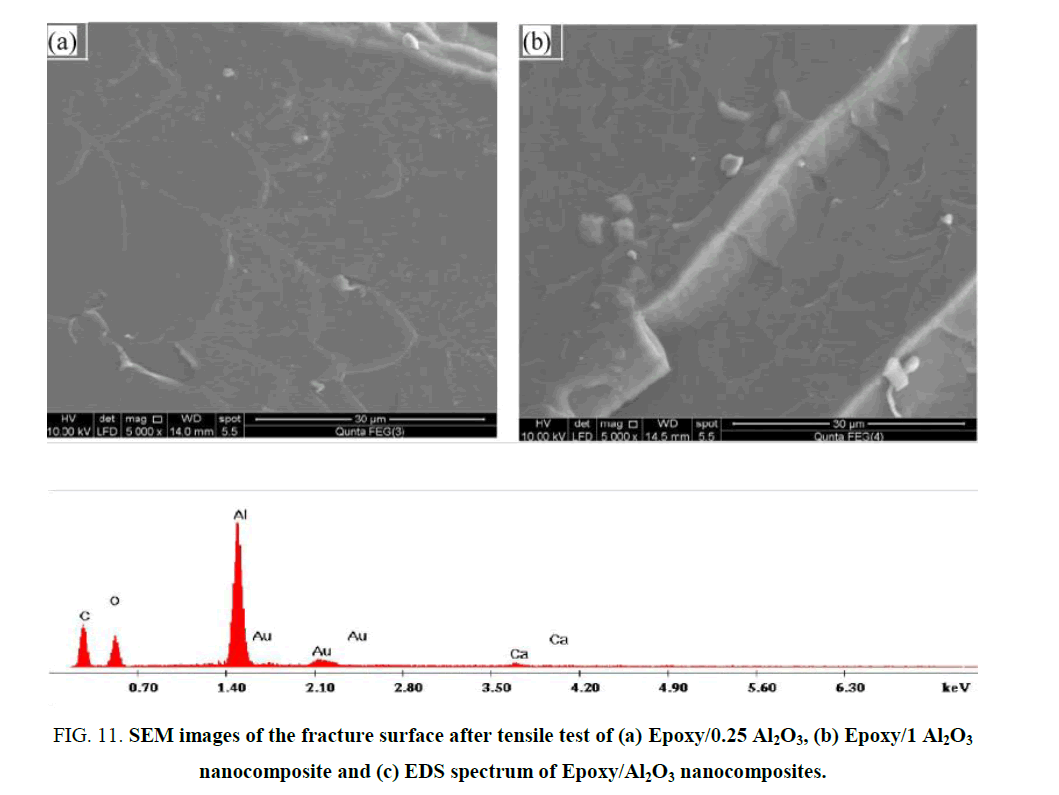

Figure 11. (a) and (b) shows the SEM micrographs of Epoxy/0.25% Al2O3 and Epoxy/1% Al2O3 nanocomposite, respectively. It can be noted that the brighter zone reflected the Al2O3 nanofiller while, the grey zone is the Epoxy matrix. When 0.25 wt% of nanoparticles was added into the composite, mostly area covered with the polymer phase as seen in Figure 11 (a). However, distribution of Al2O3 nanoparticles can be obtained when the content of Al2O3 nanoparticles is increased for 1 wt% as illustrated in Figure 11 (b). Figure 11 (c) shows the EDS spectrum of Al2O3 nanocomposites, it was seen that the elements of Al2O3 with very small amounts of calcium, carbon, oxygen and gold from the coating process.

Figure 11: SEM images of the fracture surface after tensile test of (a) Epoxy/0.25 Al2O3, (b) Epoxy/1 Al2O3 nanocomposite and (c) EDS spectrum of Epoxy/Al2O3 nanocomposites.

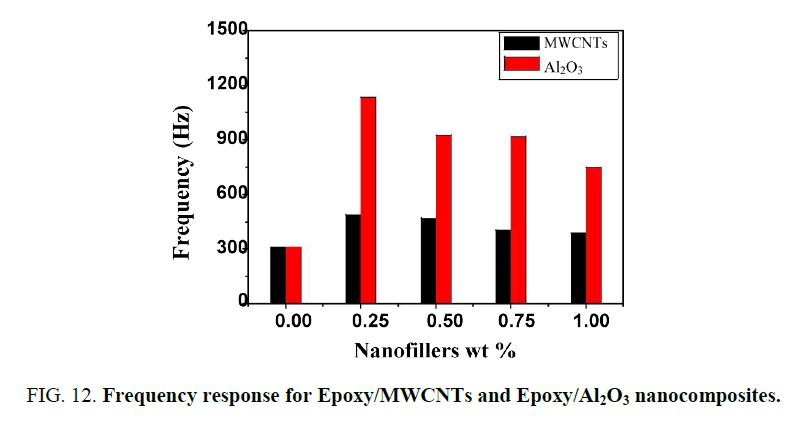

Figure 12. illustrated the variation of frequency response with increasing wt% for the two nanocomposites. It can be observed in these results, that the dynamic characteristics vary significantly after nanofillers addition. Frequency response enhanced with addition of MWCNTs and Al2O3 nanoparticles to the Epoxy matrix. It is clarifying that MWCNTs increase the natural frequency of the Epoxy matrix. The adhesion between MWCNTs and Epoxy matrix is the most important factor affects the stiffness. Higher stiffness leads to a higher natural frequency of the Epoxy/MWCNT nanocomposites [5]. Although it slowly reduced by adding 1 wt% of MWCNTs but it still higher than the neat Epoxy matrix value. Addition of Al2O3 nanoparticles to the Epoxy matrix increased the natural frequency. The comparison between the two nanocomposites demonstrates that the natural frequencies of the Epoxy/Al2O3 nanocomposite are much higher than those of the Epoxy/MWCNTs nanocomposite. These results demonstrate an advantage of nanocomposite natural frequency over neat Epoxy matrix.

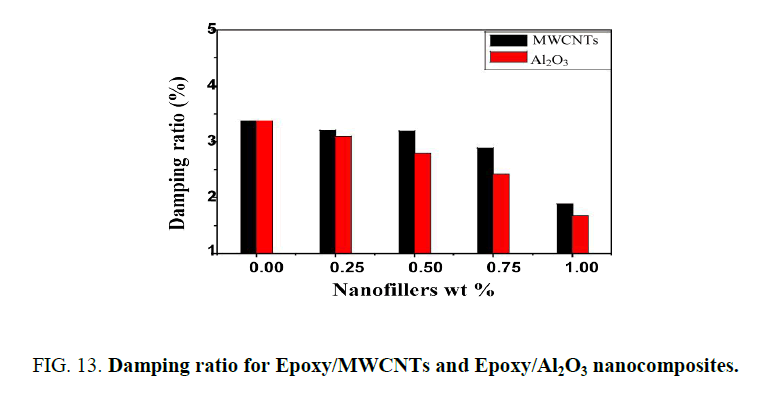

Variation of damping ratios of the nanocomposites with addition of nanofillers wt% are illustrated in Figure 13. It can be observed that the damping ratio decreased with addition of MWCNTs and Al2O3 nanoparticles to the Epoxy matrix. MWCNTs enhanced the bonding between the Epoxy resin and nanotubes causing reduction in the ability to dissipate energy and improvement in the stiffness. Good adhesion between Al2O3 nanoparticles and Epoxy matrix caused less dissipation of energy and a smaller damping ratio for the nanocomposites [5]. These results are reflected by the mechanical results shown in Figure 6 and 8.

Conclusion

Two different types of nanofillers MWCNTs and Al2O3 were used in this study. The effect of MWCNTs and Al2O3 on the mechanical properties was studied. The dynamic behavior of the nanocomposites was investigated using free vibration test. Addition of MWCNTs and Al2O3 to the Epoxy matrix leads to decline the tensile and impact strength of the nanocomposites. Incorporation of rigid nanofillers into a polymeric matrix indicates the brittle behavior of the nanocomposites which reduce the strain at break. The natural frequency of Epoxy/MWCNTs and Epoxy/Al2O3 nanocomposites increased with increasing both MWCNTs and Al2O3 loading while the damping ratio decreased. Good adhesion between the MWCNTs and Epoxy matrix caused higher stiffness which lead to higher natural frequency and lower damping ratio from the neat Epoxy matrix.

Acknowledgment

The authors are thankful to Shoubra Faculty of Engineering, Benha University for providing financial and technical support for carrying out this study.

References

- Kolsi L, Hussein AK, Borjini M, et al. Computational analysis of three-dimensional unsteady natural convection and entropy generation in a cubical enclosure filled with water-Al2O3 nanofluid. Arab J Sci Eng. 2014;39:7483-93.

- Hussein AK, Bakier M, Ben Hamida M, et al. Magneto-hydrodynamic natural convection in an inclined T-shaped enclosure for different nanofluids and subjected to a uniform heat source. Alex Eng J. 2016;55:2157-69.

- Nhuapeng W, Thamjare W, Kumfu S, et al. Fabrication and mechanical properties of silicon carbide nanowires/Epoxy resin composites. Curr Appl Phys. 2008;8:295-99.

- Haiyan C, Jacobs O, Wu W, et al. Effect of dispersion method on tribological properties of carbon nanotube reinforced Epoxy resin composites. Polym Test. 2007;26:351-60.

- Chuan HS, Lai YC. Dynamic behavior of nanocomposites reinforced with multi-walled carbon nanotubes (MWCNTs). Materials. 2013;6:2274-84.

- Laurenzi S, Pastore R, Giannini G, et al. Experimental study of impact resistance in multi-walled carbon nanotube reinforced Epoxy. Compos Struct. 2013;99:62-68.

- Wicks SS, Villoria RG, Wardle BL. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos Sci Technol. 2010;70:20-28.

- Kostopoulos V, Baltopoulos A, Karapappas P, et al. Impact and after-impact properties of carbon fibre reinforced composites enhanced with multi-wall carbon nanotubes. Compos Sci Technol. 2010;70:553-63.

- Grimmer CS, Dharan CKH. Enhancement of delamination fatigue resistance in carbon nanotube reinforced glass fiber/polymer composites. Compos Sci Technol. 2010;70:901-08.

- Laurenzia S, Bottib S, Rufolonic A, et al. Fracture mechanisms in Epoxy composites reinforced with carbon nanotubes. Procedia Engineer. 2014;88:157-64.

- Salazar JMG, Barrena MI, Morales G, et al. Compression strength and wear resistance of ceramic foams-polymer composites. Mater Lett. 2006;60:1687-92.

- Hussein AK, Hussain S. Heatline visualization of natural convection heat transfer in an inclined wavy cavity filled with nanofluids and subjected to a discrete isoflux heating from its left sidewall. Alex Eng J. 2016;55:169-86.

- Ahmed S, Hussein AK, Mohammed H, et al. Boundary layer flow and heat transfer due to permeable stretching tube in the presence of heat source/sink utilizing nanofluids. Appl Math Comput. 2014;238:149-62.

- Kordani N, Fereidoon A, Ashoori M. Damping augmentation of nanocomposites using carbon nanotube/Epoxy. Soc Exp Mech Inc. 2010.

- Devendra K, Rangaswamy T. Strength characterization of E-glass fiber reinforced Epoxy composites with filler materials. J Miner Mate Charact Eng. 2013;1:353-7.

- Youssef EKES, Mahmoud ST, El-Betar FAA, et al. Dynamic behaviour of cast A356/Al2O3 aluminum metal matrix nanocomposite. Mater Sci Appli. 2012;3:815-20.

- Man YH, Li ZC, Zhang ZJ, et al. Interface-Dependent Mechanical Properties in MWNT-Filled Polycarbonate. Mater Tran. 2009;50:1355-59.

- Khashaba UA. Nanoparticle type effects on flexural, interfacial and vibration properties of GFRE composites. Chinese J Aeronaut. 2016;29:520-533.

- Wetzel B, Haupert F, Zhang QM. Epoxy nanocomposites with high mechanical and tribological performance. Compos Sci Technol. 2003;63:2055-67.

- Gojny FH, Nastalczyk J, Roslaniec Z, et al. Surface modified multi-walled carbon nanotubes in CNT/Epoxy-composites. Chem Phys Lett. 2003;370:820-4.

- El-Bitar T, Gamil M, Mousa I, et al. Development of Carbon: Low Alloy Steel Grades for Low Temperature Applications. Mate Sci Eng A. 2011;528:6039-44.

- Chena H, Jacobsb O, Wua W, et al. Effect of dispersion method on tribological properties of carbon nanotube reinforced Epoxy resin composites. Polym Test. 2007;26:351-60.