Research

, Volume: 11( 7) DOI: 10.37532/2320-6756.2023.11(6).358Radioactivity: Shielding Materials

- *Correspondence:

- Entesser Farhan Salman

Department of Physics,

University of Babylon,

Kirkuk,

Iraq,

E-mail: bsc.entisar.farhan@uobabylon.edu.iq

Received date: 03-July-2023, Manuscript No. tspa-23-101115; Editor assigned: 07-July-2023, Pre-QC No. tspa-23-101115 (PQ); Reviewed: 21-July-2023, QC No. tspa-23-101115 (Q); Revised: 03-August-2023, Manuscript No. tspa-23-101115 (R); Published: 31-August-2023, DOI: 10.37532/2320-6756.2023.11(6).358

Citation: Salman EF, Shakir AA. Radioactivity: Shielding Materials. J. Phys. Astron. 2023;11(7): 358.

Abstract

When the rays pass through an absorbing medium such as the human body or any other organism, part of the energy of these rays is transferred to this medium. The amount of energy transferred, even in small proportions, may constitute biological damage. To reduce the risk, workers in the radiation field wear armoured coats made of protective rubber. To protect them from radiation. Attenuation or shielding of gamma radiation are an important component of radiation, safety programs aiming to reduce personnel exposure to ionizing radiation. Attenuation data for use shielding materials is commonly available in many resources such as lead and polymer composites. Polymers are high molecular weight compounds composed of units called monomers. Numerous molecules are regularly attached to each other by chemical bonds and form polymers. Polymers are used in many areas such as building materials, adhesives, electronic tool parts, insulating materials, metal materials, insulation materials, textile and paper industries.

Keywords

Shielding materials; Attenuation coefficient; Radiation; Gamma ray; X-ray

Introduction

The continuance of advance in nuclear technology led to make the radiation sources interposition in many relevant fields such as cultivation industry medicine nuclear power cohort and scientific research so the nuclear shields used to decrease the exposure to nuclear radiation and their secondary interactions with the material and to reduce the effects on human tissue. Most of these shields are made from different types of materials depending on the energy type of radiation accessibility of the shielding material. The polymerbased composites such as polyethylene polystyrene and epoxy have been selected in the field of radiation protection. In the recent years composite materials are employed in the gammaray shielding and showed good efficiency in this field. Composite materials are multiphase materials that are obtained by artificial combination of different materials so as to attain properties that the individual components by themselves cannot attain [1,2].

Materials and Methods

Gamma ray

High energy electromagnetic radiation typically emitted from the atomic nucleus during nuclear decay processes. From the properties, gamma ray: Electrically neutral, travel with the velocity of light. Penetration power is very large. It is about hundred times larger than that of alpha rays. Produce feeble fluorescence travel at the speed of light. Could only be stopped by a thick sheet of lead, steel, concrete or several meters of water. Cobalt-60, caesium-137, zinc-65 and radium-22 are gamma emitters [3,4].

X-ray

Fundamentally the same as gamma rays, but originating from electrons outside the atomic nucleus. Some resources may also distinguish gamma rays and x-rays based on energy. X-rays properties are given. They have a shorter wavelength of the electromagnetic spectrum. Requires high voltage to produce x-rays. They are used to capture the human skeleton defects. They travel in a straight line and do not carry an electric charge with them. They are capable of travelling in a vacuum [5,6].

α-partical: α-partical is emitted during the decay process. Such nuclei have high proton to neutron ratio. α-particles are quiet stable in their configuration with two protons and two neutrons. Protons to neutron ratio is reduced in the parent nucleus decay by altering the Z. So the parent and the daughter atoms are chemically different elements [7,8].

The capacity of the α-particle to penetrate materials is not very great, it usually penetrates no more than a few centimetres in air and is absorbed by a relatively small thickness of paper or human skin. However, because of their speed and size, they are capable of ionising a large number of atoms over a very short range of penetration. This makes them relatively harmless for most sources that are about a metre or more away, as the radiation is easily absorbed by the air. But if the radiation sources are close to sensitive organs α-particle radiation is extremely dangerous [9,10].

β-particles: Beta-particle radiation consists of fast moving electrons. Every β-particle carries either one negative or one positive electronic charge (± 1.6 × 10-19 coulomb: -e, +e). They are affected by electric and magnetic fields. The speed depends on the source, but it can be up to 90% of the speed of light. Β-particles can penetrate up to 1 m of air. They are stopped by a few millimetres of aluminium or perspex. Their ionising capacity is much less than that of α-radiation. They are very dangerous if ingested [11,12].

Interaction of radiation with the material

The ways in which the rays interact with the material vary depending on the type, extent and energy of these rays. In our subject, we discuss gama's interaction with the x-ray with the material [13,14].

Photoelectric effect: The complete transfer of energy from a gamma ray photon to an atomic electron of the shielding material. Photoelectric absorption is more common for lower energy gamma radiation (<500 keV) and for shielding materials constructed from high atomic number elements, such as tungsten, lead and bismuth [15].

Compton scattering: The transfer of part of the energy of a gamma ray photon to an atomic electron of the shielding material. After undergoing compton scattering, the gamma photon may undergo further scattering or absorption interactions with the shielding material and/or emerge from the shielding material with diminished energy. Compton scattering is predominant at relatively high gamma energies (500 keV-1500 keV) and for shielding constructed from low atomic weight materials.

Pair production: An interaction of a gamma ray photon with the nucleus of an atom which results in the creation of beta particle and a positron. The positron, then undergoes an annihilation reaction with an electron to produce two 511 keV gamma rays. The incident gamma radiation must have a minimum energy of 1022 keV to undergo pair production. Pair production becomes an important attenuation interaction for very high energy radiation (>1500 KeV).

Results and Discussion

Attenuation coefficient

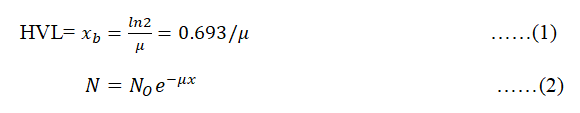

A magnitude that describes how simply electromagnetic radiation enters a material. The coefficient of attenuation (μ) can be represented by two units. 1) When measuring the thickness of the material (x) in cm, the calculated attenuation coefficient will be in units (cm-1) called the total linear attenuation coefficient (μ) and the total linear attenuation coefficient depends on the energy of the falling photon, the atomic number (z) of the attenuated medium and the mean density (ρ). 2) When the thickness of the attenuated medium (x) in mass units per unit area (g/cm2). The attenuation coefficient and the material density can be used to estimate the transmission of gamma radiation through a chosen thickness of shielding material or the thickness of a shielding material required to achieve a desired level of attenuation. Gamma attenuation coefficients are inversely dependent on gamma energy and directly proportional to the atomic number of the element from which the shielding material is constructed. It is normal when the rays pass in a certain material, the intensity of these rays will decrease and lose part of its energy as a result of losing it due to absorption by the material. The special thickness that attenuates the beam to 50% is called the half-value layer or.

For shielding materials were published data isn’t available, attenuation can be estimated through calculation. The attenuation of gamma radiation (shielding) can be described by the following equation:

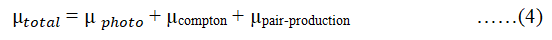

Where I=Intensity after shielding, Io=Incident intensity, μ=Mass absorption coefficient (cm2/g), ρ=Density of the shielding material (g/cm3) and t=Physical thickness of the shielding material (cm). A plot of the total mass attenuation coefficient vs. absorption coefficient (μ or μtotal) is actually the sum of the attenuation coefficients of photoelectric absorption, compton scattering and any other mechanism that is important for a given gamma energy:

| Material | Density (g/cm3) | Material | Density (g/cm3) |

|---|---|---|---|

| Water | 1 | TFlex®-Fe | 2.8 |

| Aluminum | 2.7 | TFlex®-50 | 3.8 |

| Iron | 7.86 | TFlex®-Bi | 4.7 |

| Copper | 8.96 | Flex®-W | 7.2 |

| Bismuth | 9.8 | - | - |

| Lead | 11.34 | - | - |

| Tungsten | 19.3 | - | - |

TABLE 1. Physical properties of shielding materials.

Polymer composites for γ‑radiation shielding

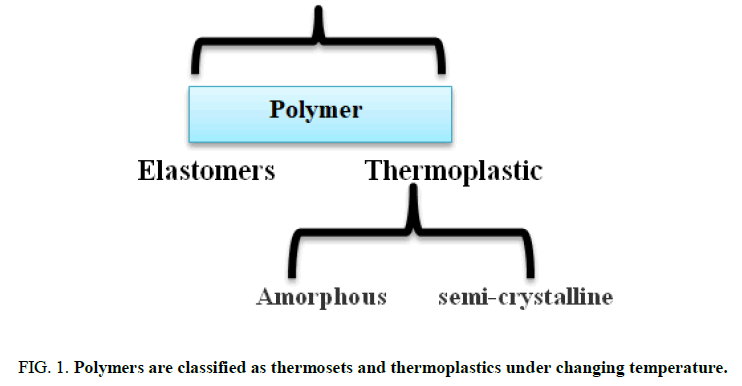

Special clothing has been used to protect medical personnel, doctors and nurses and their patients, to protect against direct and secondary radiation during diagnostic imaging, resonance imaging or scans in hospitals, clinics and dental offices. Use lead to protect against radiation. However, technological advances in radiation shielding materials have led to the production of two alternative materials, the lead-free radiation shield material. And lead compounds and nanomaterials or nano-lead. Polymers are substances containing a large number of structural units joined by the same type of linkage. These substances often form a chainlike structure. It has been approximately 60 years since researchers first began exposing polymeric materials to ionizing radiations and today, a substantial commercial industry is in place based on the processing of polymers with radiation. Polymers are of low atomic number and low density and thus lightweight materials. Polymers possess high durability and they are tough. Also, they are cost-effective, need low maintenance and stable over a wide temperature range. Based on processing under changing temperature, polymers are categorized as thermosets and thermoplastics as listed in the Figure 1, also thermoplastics including elastomers can be divided into semicrystalline and amorphous polymers. Both the thermoset and thermoplastic.

FIG 1: Polymers are classified as thermosets and thermoplastics under changing temperature.

Conclusion

An amorphous thermoplastic material has no specific molecular structure and is normally a solid, clear, stiff material with low shrinkage, for example, polystyrene. In comparison, a crystalline polymer has an systematized, “crystal-like” structure, but also comprises of amorphous material. It is usually known as a semi-crystalline thermoplastic material. These types of plastics are commonly tougher and less fragile compared to amorphous thermoplastics. It is also common for them to have a higher heat distortion temperature. Additionally, these plastics are translucent or opaque and have a high shrinkage. Several categories of materials have been used as radiation shielding barriers to keep a safe environment for everyday practice in all radiation conveniences. Several features can classify the proper shielding material to be used, including a high atomic number for gamma radiation shieldings such as (Ba), (Pb) and (Bi). Whereas elements of low atomic numbers are preferably used for neutron attenuation. However, many constraints burden the use of such modern shielding materials such as the cost, heaviness and toxicity. To improve the polymer performance and characteristics, a stiff material called filler can be added to the polymer matrix to form a polymer composite. The combination between the filler and the polymer matrix provokes the formation of a mixture that influences the polymer-composite properties by retaining the properties of both the filler and the polymer. The composite materials are named according to the reinforcement and the matrix material constituting them. There are many types of matrix materials such as metal matrix composites, polymer matrix composites, ceramic matrix composites and epoxy resin matrix composites. The availability of radiation shielding materials that can be moulded into specific shapes and used even at high temperatures is quite significant for medical and industrial procedures.

The resistance of a material to radiation is attributed to many factors such as the type of radiation used, the rate of absorbed dose, radiation exposure (pulsed or continuous), area and size of the material, the surrounding environment (pressure, temperature, electric or magnetic field. But in inorganic materials, the radiation resistance depends on the type of chemical bond and crystal structure of the material. Due to relatively high processing ability and durability, polymer composite materials are vastly used in various fields of industry. Since 1916, the first polymer composite was used as a phenol-formaldehyde resin (wood flour) by bakelite. Recently, about 10,000 fillers are known and used. The main duty of the filler is to provide the material with special properties and cost effectiveness. Composites of polymer materials are superior due to their merits in flexibility, low cost, workability, mechanical stability, high aspect ratio. Also, the research studies confirmed that composite materials not only are better in radiation resistance, but also have thermal stability and high mechanical properties. Numerous studies have reported the use of polymer composites as gamma-radiation shields.

References

- Hashim AK, Najam LA, Mohammed EJ, et al. Estimation of radon exhalation rate, radium activity and uranium concentration in biscuit samples in Iraq. Iran J Med Phys. 2019;16(2):152-157.

- Loginov YP, Kazak AA, Yakubyshina LI. The yield rate and quality of tubers of early ripening potato varieties in the conditions of organic agriculture of the Tyumen region. Ann Agri Bio Res. 2019;24(1):76-81.

- Jain AN, Nicholls A. Recommendations for evaluation of computational methods. J Comp Aided Mol Des. 2008;22:133-139.

[Crossref] [Google Scholar] [PubMed]

- Imbabi MS, Carrigan C, McKenna S. Trends and developments in green cement and concrete technology. Int J Sustain Built Environ. 2012;1(2):194-216.

- Gowda S, Krishnaveni S, Yashoda T, et al. Photon mass attenuation coefficients, effective atomic numbers and electron densities of some thermoluminescent dosimetric compounds. Pramana. 2004;63:529-541.

- Chaiphaksa W, Limkitjaroenporn P, Kim HJ, et al. The mass attenuation coefficients, effective atomic numbers and effective electron densities for GAGG: Ce and CaMoO4 scintillators. Prog Nucl Energy. 2016;92:48-53.

- Ladhaf BM, Pawar PP. Studies on mass energy-absorption coefficients and effective atomic energy-absorption cross sections for carbohydrates. Radia Phys Chem. 2015;109:89-94.

- Taqi AH, Khalil HJ. An investigation on gamma attenuation of soil and oil-soil samples. J Radia Res Appl Sci. 2017;10(3):252-261.

- Madbouly AM, Atta ER. Comparative study between lead oxide and lead nitrate polymer as gamma-radiation shielding materials. J Env Pro. 2016;7(2):268-276.

- Fujii Y, Taniguchi N, Itoh K, et al. A new method for attenuation coefficient measurement in the liver: Comparison with the spectral shift central frequency method. J Ultrasound Med. 2002;21(7):783-788.

[Crossref] [Google Scholar] [PubMed]

- Oleksy M, Heneczkowski M, Galina H. Chemosetting resins containing fillers. I. Unsaturated polyester resin compositions containing modified smectites. J Appl Polym Sci. 2005;96(3):793-801.

- Aubry M, Cantu R, Dvorak J, et al. Summary and agreement statement of the first International Conference on Concussion in Sport, Vienna 2001. Br J Sports Med. 2002;30(2):57-63.

[Crossref] [Google Scholar] [PubMed]

- Babu MS, Somashekar RK, Kumar SA, et al. Concentration of uranium levels in groundwater. Int J Sci Environ Technol. 2000;5:263-266.

- Amelino-Camelia G. Doubly-special relativity: First results and key open problems. Int J Mod Phys B D. 2002;11(10):1643-1669.

- Shakir AA, Salman EF, Shakir AJ, et al. Optical properties of polyvinyl alcohol membrane with n-HAp for bio-medical applications. Prensa Med Argent. 2019;105(11):836-841.